Following up on our log “Today I Built a Vagina,” here is the progress we have made to our jig.

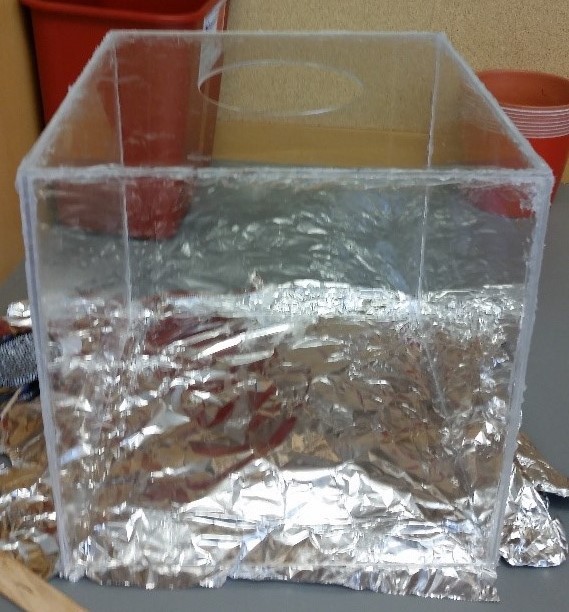

We created an enclosure for our experimental jig. This enclosure was cut from a 0.98” x 30” x 36” clear acrylic sheet. Using a laser cutter, we cut down the sheet into 6 panels measuring 10 x 10” each. One of the panels was cut to have an additional 3 in diameter hole in the center. A marine sealant was used to join the acrylic squares together, and the apparatus was left to dry for 24 hours. We used marine sealant to ensure that the enclosure would be leak-proof.

The PDMS structure made on June 23rd was recreated to add texture and slight angling to the inside of the “vaginal cavity” to better reflect anatomical measurements. A PDMS base (150mm diameter x 4mm thickness) was then added to the bottom of the vaginal structure to provide standing support. The “vaginal cavity” was joined with the enclosure (bottom panel with 3” diameter whole) using marine sealant.

A thermometer and aquatic heater were also added to the inside of the enclosure. Using this set up, we plan on filling the enclosure with water and heating it up to body temperature, allowing us to gauge heat sensitivity and its effects on our product.

We are using an IV bag, IV flow regulator, and various needle gauges to simulate the menstrual flow into the “vaginal cavity”. The needle will be inserted into the top of the “vaginal cavity,” and the gravity/flow regulator will regulate “flow” from the IV bag. We are currently using saline as our “flow” material, but are looking into more accurate approximations of menstrual fluid to test with as well.

Katherine

Katherine

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.