I was inspired by the previous post concerning ceramic heaters for hot plate SMT soldering. I sought out another method and found PTC heaters, cheap heaters encased in aluminum that self regulated their max temperature. I bought one that was a max temperature of 230C and found that it would reflow SMT parts very well...and for just $10 from Amazon!

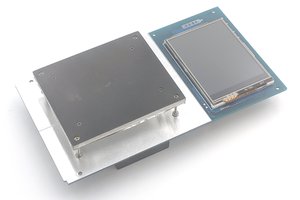

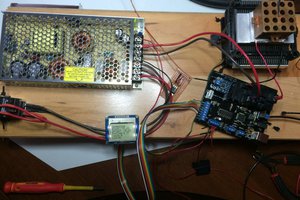

Experimental setup:

I used a 200W 110V PTC Heater with a regulated temp of 230C. I used an old Pentium II heatsink as a stand for the heater. I used a power cord scavenged from a broken rice cooker as the mains hookup. I tied the power cord and heater together with screw terminals.

I documented my test results in the first project log. In short, the PTC heater is a very economical and simple way to get started with hot plate SMT soldering small PCB boards.

Analog Two

Analog Two

Vitaly

Vitaly

Katherina Baranova

Katherina Baranova

SAYANTAN PAL

SAYANTAN PAL