After a few weeks of calibration, it is time to show some pictures :)

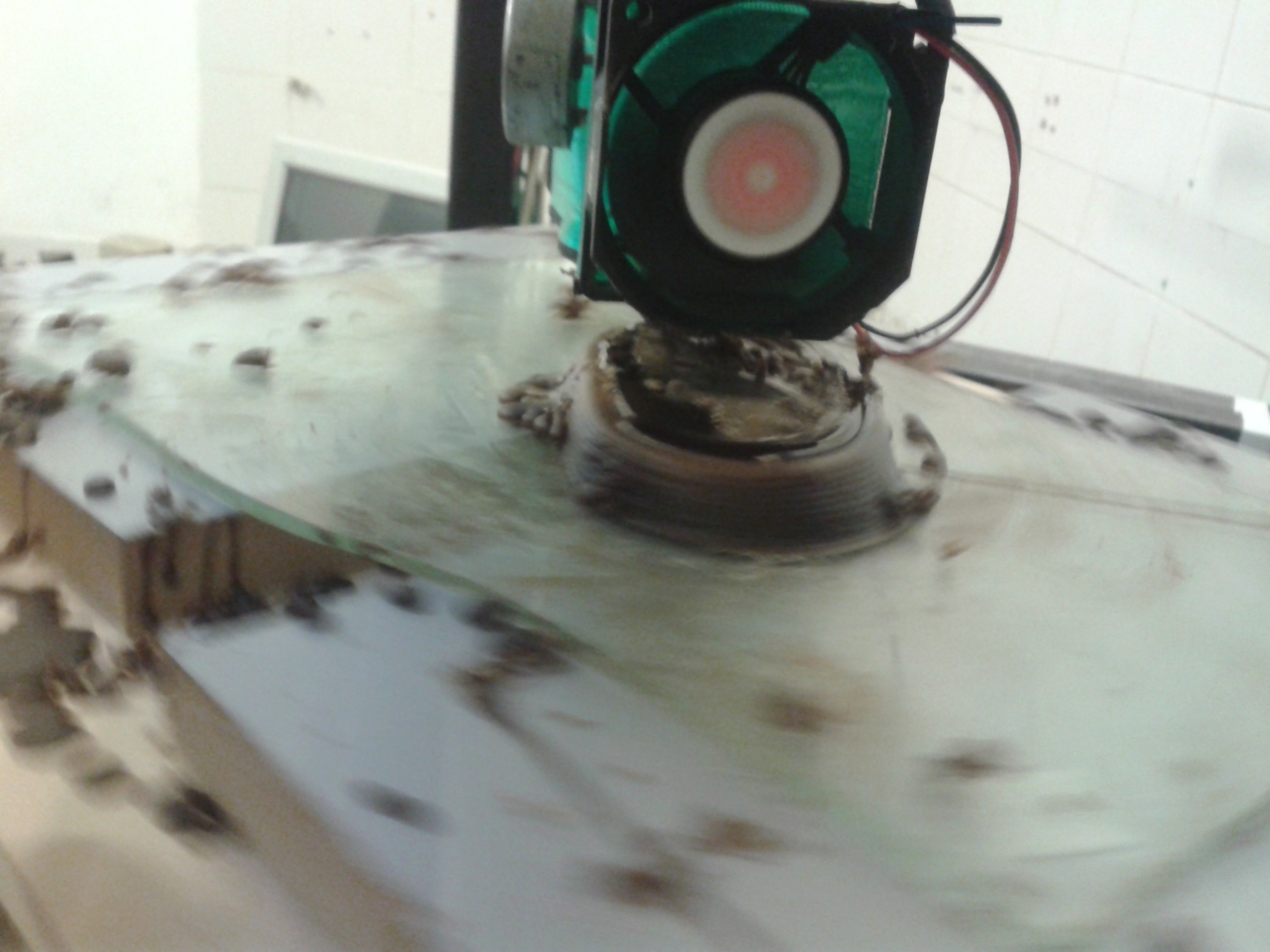

We made a cooling rig (in green) to help solidifying the wax.

Previous prints where fine only in small sizes buy our goal is printing big objects with it so we have to deal with the object temperature.

One of the biggest disadvantages of using wax as print material is the low melting point of 67C.

Ambient temperature does not help in cooling the print fast enough between layers so we had to add a cooling rig.

Once we added the rig we found another issue...the was is coming out almost liquid and blowing air will throw the wax away from the print.

Keeping the coolers below 50% power help controlling that and provide a better cooling.

This improved the print A LOT, but proved insufficient on big and solid prints.

The example below is 10mm high with 100% infill on every layer.

Some perimeters failed to solidify completely and where dropping from the object like seen on the left.

We are adding a peltier element to blow cold air and help cooling the wax.

Nice thing about printing with wax is that all mistakes can be remelted and reused :)

Here is a short video showing the issues we have when printing tall objects.

You'll see the top layer is not solid enough and we had to constantly remove molten material to keep going.

The biggest print we where able to complete was 250mm x 200mm x 75mm.

More news once we add the peltier to the cooling rig!

nfk

nfk

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.