This project started as a fun project for a Scout group and then took over. Initially the goal was to make a simple, cheap and easily constructed project for the Scouts. Then reality happened. I realised that very few brush bots out there are autonomous, with hindsight I think that this is because of the irregularities created by using a brush and vibration motor combo. Inspired by the Kilobot project I continued.

The problem with the kilobot project is the robots aren't east to setup calibrate and use, they are much more capable than my design.

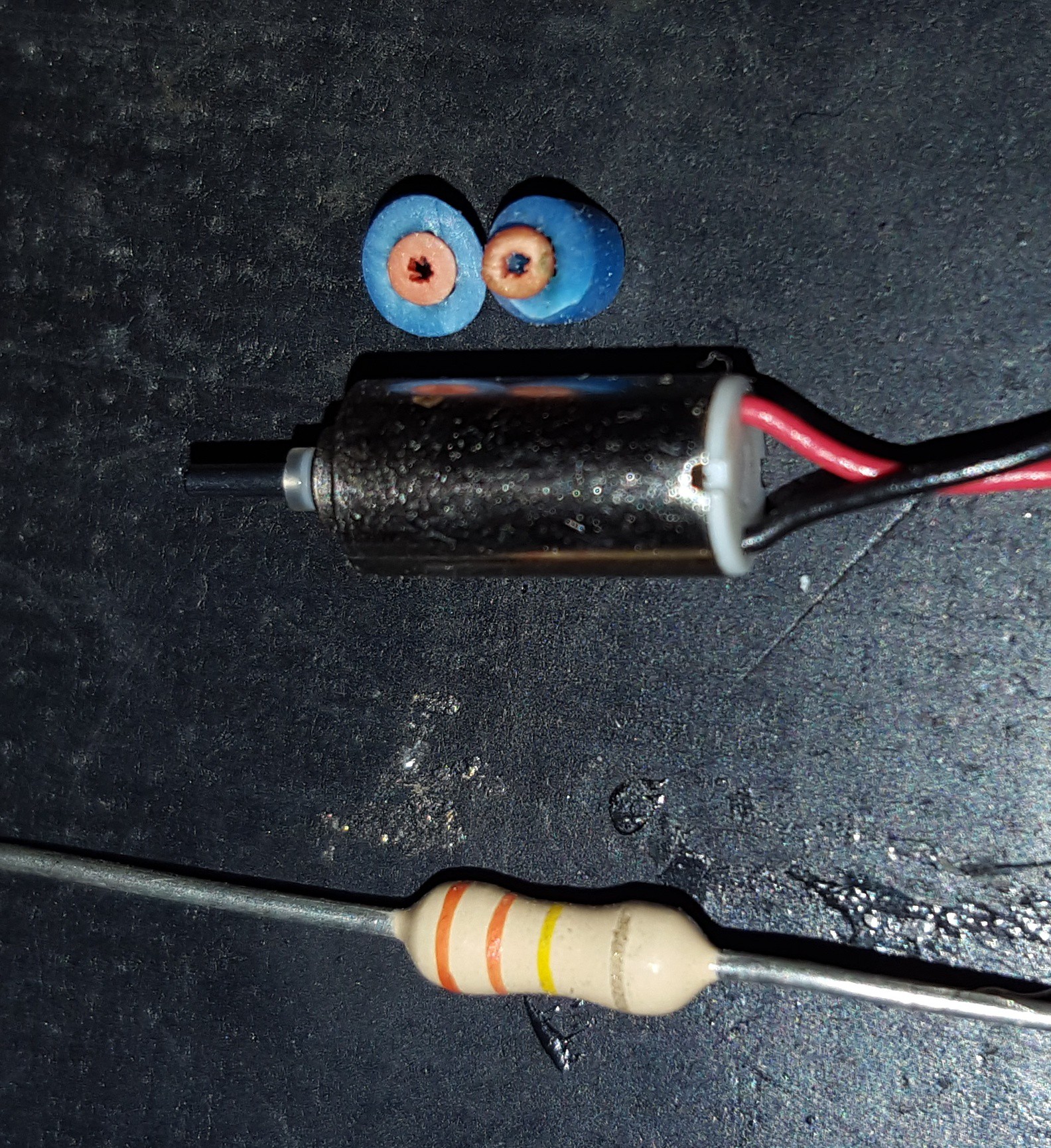

The kilobots use single pins in their design, my trials with these have been unimpressive, I've had much more success with brushes. I've tried many sorts of brushes from velvet to draught excluder, but tooth brushes work best for me.

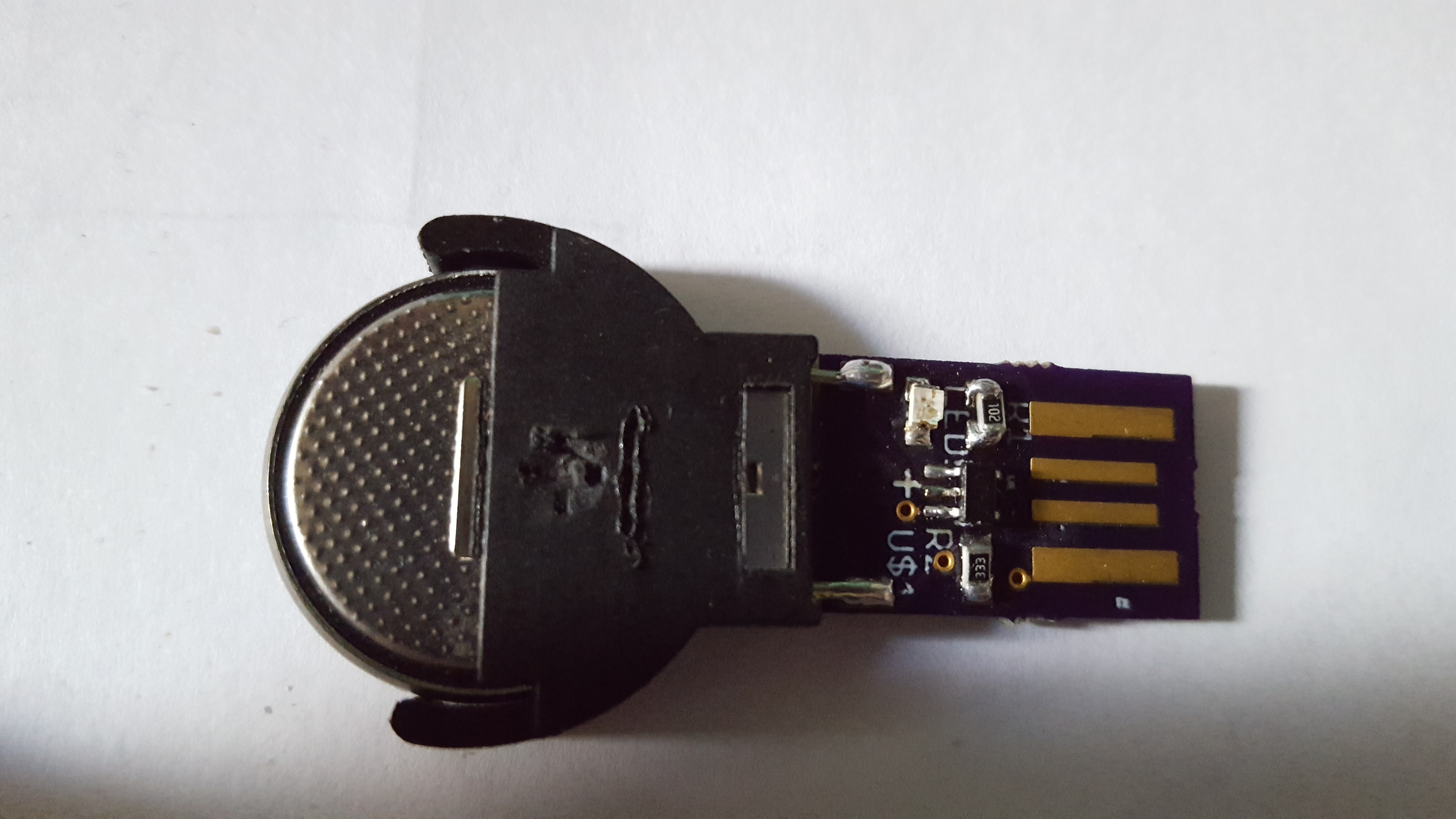

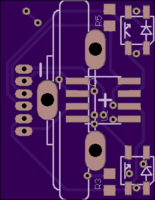

The problem with any sort of brush, its its operation is pretty much random exactly not what you want from a robot drive system, although the software does try to allow for this it isn't perfect. The decision to go to a small uP control rather then a discrete control solution was taken very early on to give me some fiddle room / processing with the signals. This has allowed me to have a Shmitt like responce on the IR detectors and PWM for the motors and with the latest boards a calibration "learn" mode.

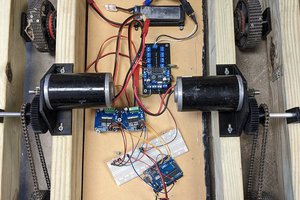

Although the main focus has been on a black line following brush robot, I would like to develop this into a small platform for any power train, motors, gears, wheels, lasers, Em drive etc.

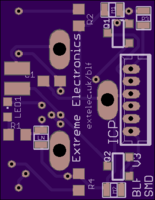

Extreme Electronics

Extreme Electronics

The Big One

The Big One

Oskar Weigl

Oskar Weigl

David

David

ironBit

ironBit

Some quick notes:

In the parts list:

LIR2023 should be LIR2032?

I am having a hard distinguishing/sourcing the following pieces. Could you link to some examples?

8pin DIP turned pin low level socket. (I don't know what 'turned pin low level' means)

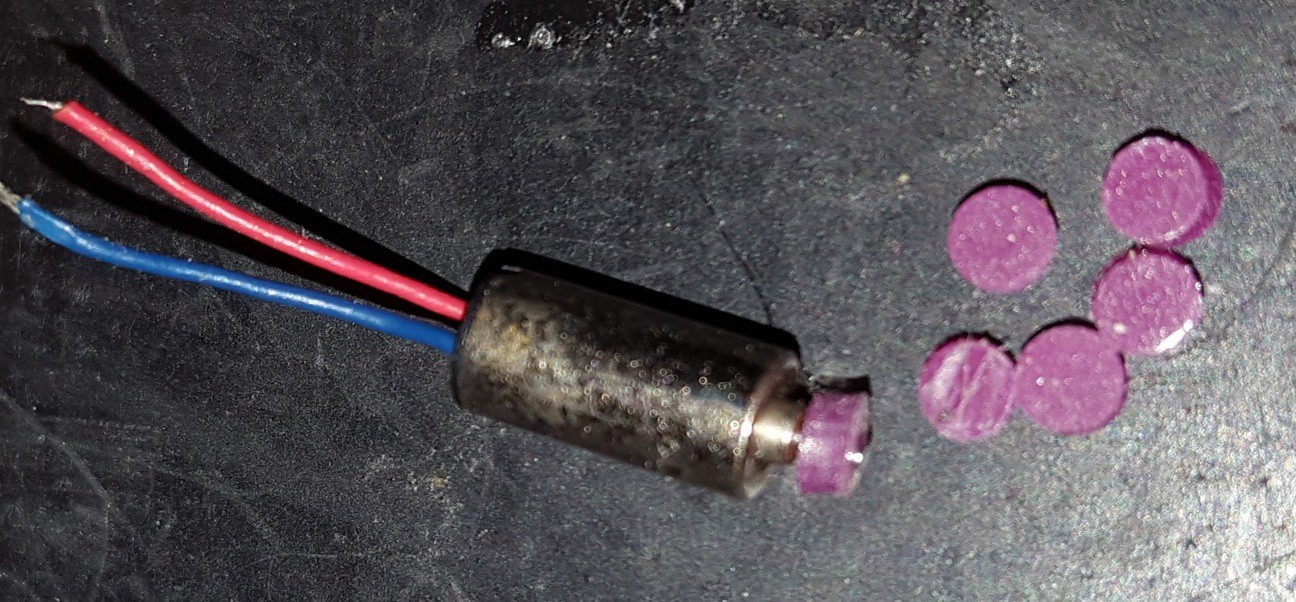

8mm Disk Vibration Motors (I can find 10mm motors all over but no 8mm)

Small details and I have already ordered a number of things that I believe will work. We will be building in a class setting so I want to make sure we get parts right. :)