I made a satisfactory toggle (divide by 2) circuit that will run from a 5 Hz clock:

Here is a video showing an attempt at making a divide by 3 circuit:

The three large SP2ST relays are not very consistent in operation. They have 4 throws closing on a common pole, used as two throws with redundant paired contacts.

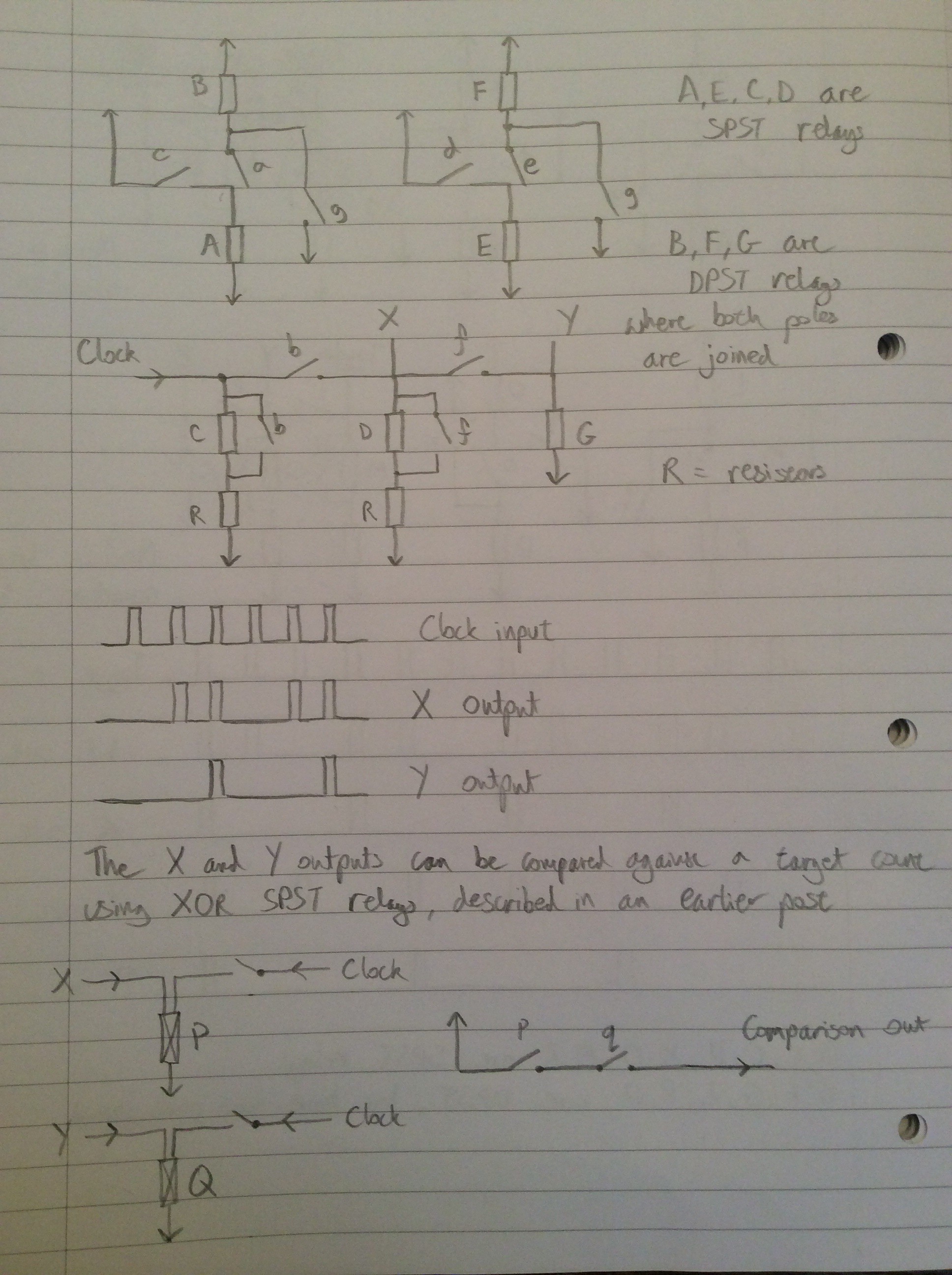

Here is a circuit diagram for the divide by 3 circuit:

A divide by four circuit can be made along similar lines.

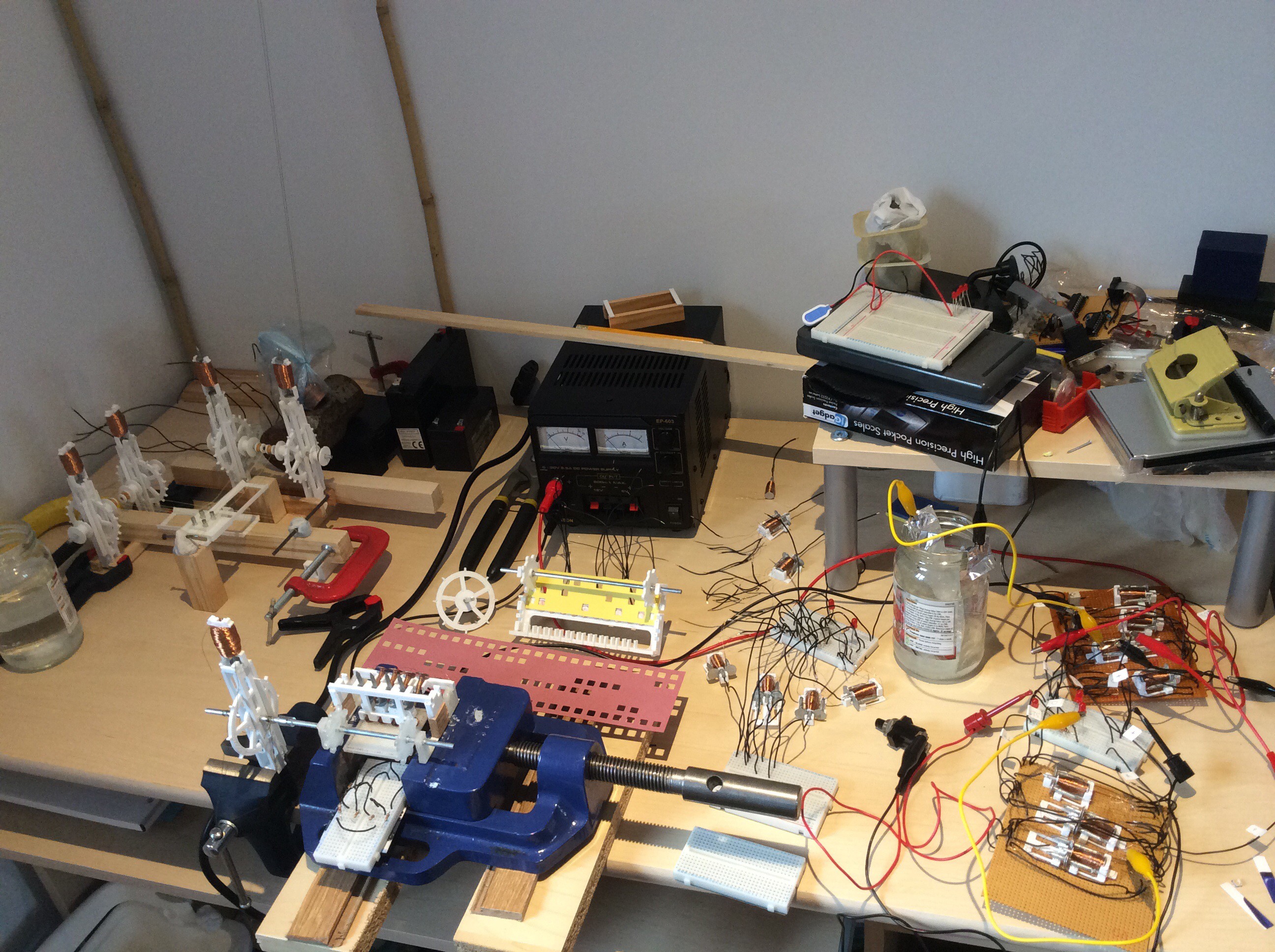

I didn't make a working prototype plotter before the Hackaday Prize deadline, here's a photo that illustrates progress made:

Apart from not meeting that deadline, I'm pleased with how the project is going. After several rethinks, the control circuit design is much simpler than it was when I started thinking about it in January without sacrificing much functionality - I initially thought I'd need over 100 relays, now I think I'll need about 20. The motors work well enough to be used to drive the axes and the punched card reader. I've made a simple, working, axis movement mechanism. The punched card reader worked after only a couple of design iterations (but I haven't properly assessed how reliable it is). I'm pleased with the simplicity of the motors and the speed at which they can be stepped (at least 8 Hz) and the rate at which prototype DIY relay circuits can be clocked (at least 5 Hz).

I need to go back to the drawing board for the relays, and spend time improving them and reducing the time that it takes to make them. One way of reducing the construction time could be to make a 3D printed coil winder that can wind several coils at once. I also want to investigate using copper or silver as contact materials, which should give better performance than galvanized nails. I also found that the clout nails I used sometimes have sharp protrusions on the shaft side of the nail head, I believe that in a few cases these were sharp enough to cut through the enamel on the copper wire and cause the coil to make contact with the nail, which I didn't notice until I came to use them.

will.stevens

will.stevens

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.