To make it more scalable we are finding ways to cut down the cost of the components. Most of the components can't be changed such as camera, Rpi and lens (already using a plastic lens instead of glass lens) this left us with the mirrors.

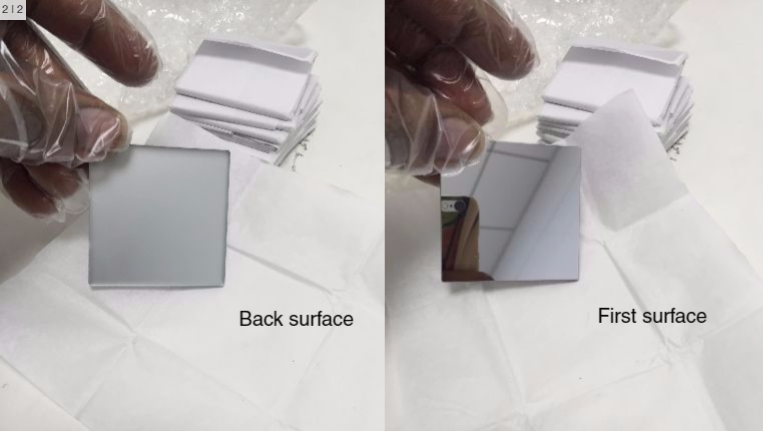

The present mirrors cost us $42 each that are from Edmund optics and we have two mirrors which is a lot. These mirrors are front end mirrors with first surface reflection which helps get optically perfect reflections and prevents getting ghost images. So we thought of converting a regular mirror into a first surface mirror. For doing that we should remove the protective layer at the back side of the mirror. So we used a paint stripper to remove the paint from the normal mirror and cleaned them to get a perfect clear glass.

But the paint removal process removed the reflective aluminium coating which reduced the reflectivity thus striking off the idea.

We searched with many local vendors for those mirrors and we found a provider for single surface front end mirrors form opticsindia which are locally manufactured. This is costing us $6 each. This cuts down the cost to a larger extent.

Sandeep

Sandeep

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.