Ridiculously advanced air quality monitoring station, enclosed in a compact aluminium body for rugged design, it has sensors for Gamma radiation, formaldehyde, CO2, tVOC Air quality +temperature, barometric pressure, air humidity, and a laser scattering sensor for PM2.5 particulate matter. The A3 also comes in 4 variants, with the same sensors but offering different connectivity options: Ethernet, Wifi, GSM (with a data sim card) and LoraWAN.

Detection interval

– background Gamma Radiation: 0 .. 9999μSv/h

– PM1.0/2.5/10.0 particulate matter: 0 .. 1000μg/m³

– formaldehyde: 0..5ppm

– CO2 400..5000ppm

– air temperature: -40 .. +85C

– air humidity: 0 .. 100% RH

– air quality / VOC: 0..100mg/m³ reducing gases and 0..10mg/m³ oxidising gases

– barometric pressure: 300 .. 1100hPa

– HW105+ only: noise pollution: 30dBA .. 130dBA

May 2017 - HW105

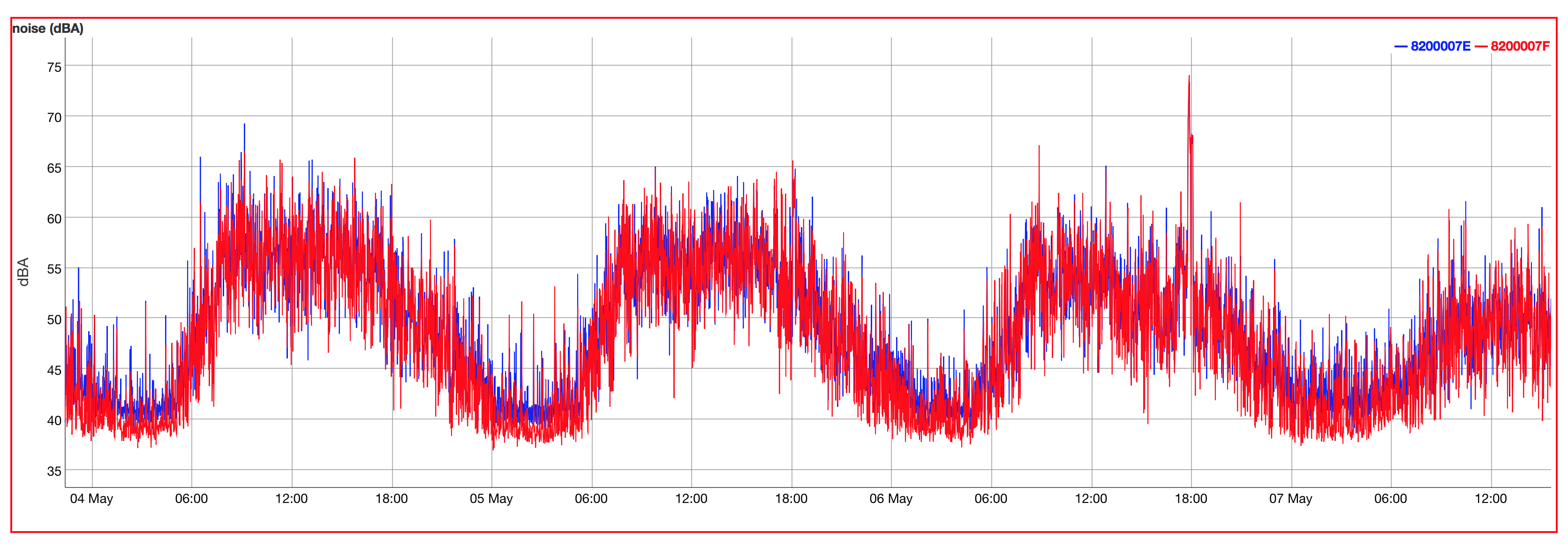

Finally, both attempts that failed in HW104 were brought to a solution. A sound amplifier circuit based on MAX4466 allowed good dBA noise calculations, while a new VOC sensor was tested, with excellent results. Finally, the uRADMonitor A3 has noise pollution detection capabilities:

Picture shows elevated readings due to auto traffic during day, with data from two nearby units functioning concomitantly.

February 2017 - HW104

I wanted to add a sound sensor, and find an alternative to the VOC detection currently implemented with the BME680 from Bosch. I tried an electret microphone amplifier circuit and the GM502B sensor, but wasn't happy with the results. Design dropped.

September 2016 - HW103

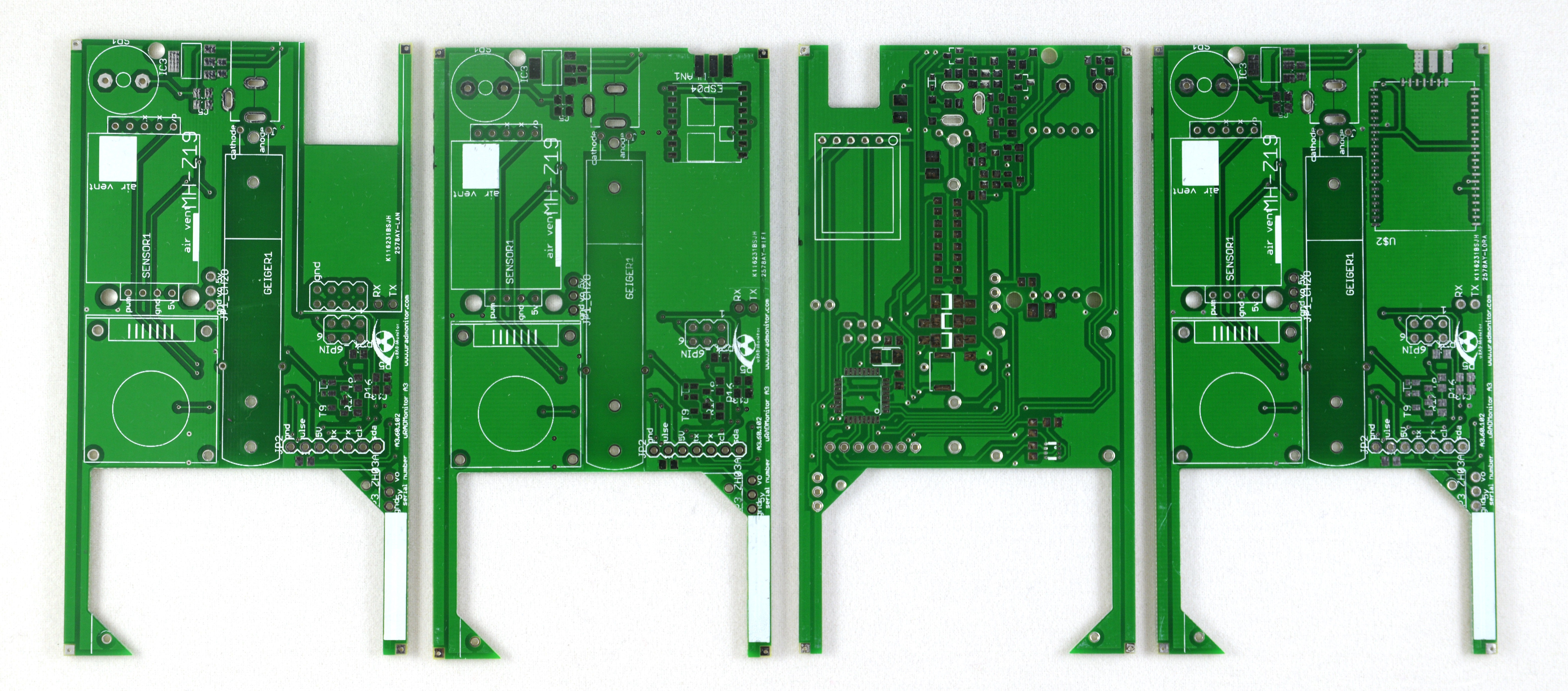

This variant was a success. 4 PCB versions to hold the same sensors but offer 4 different connectivity options: Ethernet (via enc28j60), Wifi (via ESP8266-ESP04), GSM (via SIM800) and LoraWAN (via RN2483 / RN2903).

The enclosure was reworked as well, to use a new profile that comes with wall mounting brackets. The one that came closer to my size requirements had a smaller width and this impacted the new PCBs. I also made two types of enclosures, one with a rectangular opening for the Ethernet cable connector, and one with a round hole to fit the SMA antenna connector, serving all 3 radio variants.

The enclosure was reworked as well, to use a new profile that comes with wall mounting brackets. The one that came closer to my size requirements had a smaller width and this impacted the new PCBs. I also made two types of enclosures, one with a rectangular opening for the Ethernet cable connector, and one with a round hole to fit the SMA antenna connector, serving all 3 radio variants.

The sensors in these units stayed the same. Bosch BME680 for temperature, pressure, humidity and VOC, the laser light scattering sensor for PM2.5, the NDIR CO2 sensor and the electrochemical formaldehyde sensor. The SI29BG Geiger tube remained responsible for the radiation readings. This tiny unit of about 11cm long, was therefore capable to measuring 8 air parameters, sending the data over 4 distinct channels: Ethernet, Wifi, GSM or LORAWAN.

The sensors in these units stayed the same. Bosch BME680 for temperature, pressure, humidity and VOC, the laser light scattering sensor for PM2.5, the NDIR CO2 sensor and the electrochemical formaldehyde sensor. The SI29BG Geiger tube remained responsible for the radiation readings. This tiny unit of about 11cm long, was therefore capable to measuring 8 air parameters, sending the data over 4 distinct channels: Ethernet, Wifi, GSM or LORAWAN.

The system drew the attention of Orange, and I started a partnership with them to install several such units in a few cities. One such example was the city of Alba Iulia, the first Romanian smart city, where 15 A3 units were installed in public transportation. The data is available online, here.

This became an excellent way to use my toys in the real life environment, but also to learn to raise up to the challenge of making everything work as expected. Some time after, the system is still functioning unattended, providing precious readings on the air quality. For a few months I was busy building by hand a few tens of these devices, running tests and making sure everything is perfect. But it was worth it, and I'm proud of the accomplishment.

This became an excellent way to use my toys in the real life environment, but also to learn to raise up to the challenge of making everything work as expected. Some time after, the system is still functioning unattended, providing precious readings on the air quality. For a few months I was busy building by hand a few tens of these devices, running tests and making sure everything is perfect. But it was worth it, and I'm proud of the accomplishment.

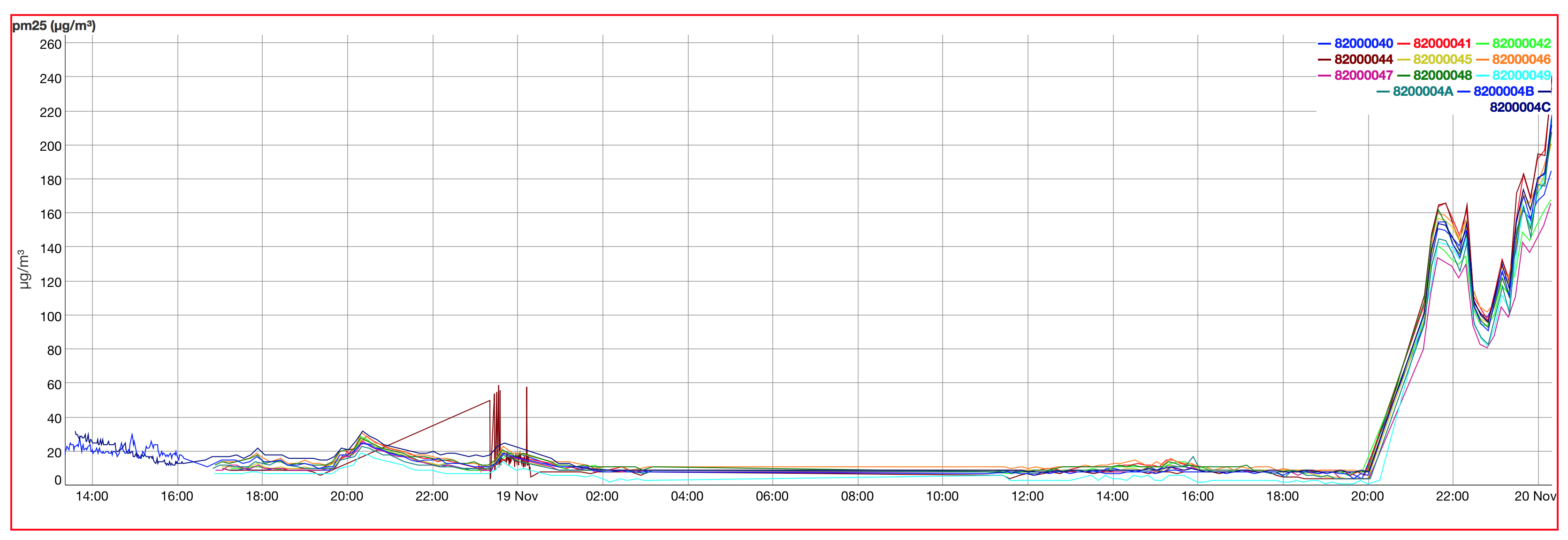

And talking about the data, here are some of the tests, showing the output from several devices running in parallel. These are PM2.5 measurements, counting particles as small as 2.5 microns in diameter, and you can see the devices agree on the values:

And talking about the data, here are some of the tests, showing the output from several devices running in parallel. These are PM2.5 measurements, counting particles as small as 2.5 microns in diameter, and you can see the devices agree on the values:

Sweet!

Sweet!

July 2016 - HW101, 102

These versions had some issues. First I tried to use the previous HW100 design, and add extra connectivity options: instead of the Ethernet module for wired connectivity, I needed more options: Wifi, GSM and LoraWAN. Replacing the Ethernet module with modems for the radio variants was easy, but I placed the 8MHz crystal oscillator too close to the High voltage inverter coil (used for the Geiger Tube circuit) and the system clock was getting some interference, causing endless trouble.

One solution was to disable external oscillator and go for the internal 8MHz variant, but I wasn't too happy about it. Then one of the sensor was updated to a different form, and didn't fit the previous footprint.

So all in one, I decided to redo the PCBs, paying extra attention to the small details.

May 2016 - HW100

This was the first iteration of this project. The circuit included a DC IN protection circuit, that would prevent any damage from reversed polarity or over voltage, as the units were designed to be installed in buses, using the voltage infrastructure there.

HW100 - The enclosure

Following the direction crystallised by the previous uRADMonitor devices, we’ve opted for a high quality rugged metallic enclosure made of anodised aluminium. I used a round aluminium profile, anodised black and with white silkprint.

Optional end plates include wall mounting sockets.

HW100 - The software

For this new model, we’re currently making changes to the way the information is being presented to the end user. The new measurements need more intuitive representation in regards to the air quality: a simple but informative dashboard, presenting an air quality index and the factors that can impact our health

The new model is currently in testing phase, and if all goes well should see production by the end of June 2016. The data collected by these units will have a signifiant relevance to human health and will help us understand pollution factors in cities, busy streets, offices, production centres and homes, contributing to an improved quality of life.

Radu Motisan

Radu Motisan