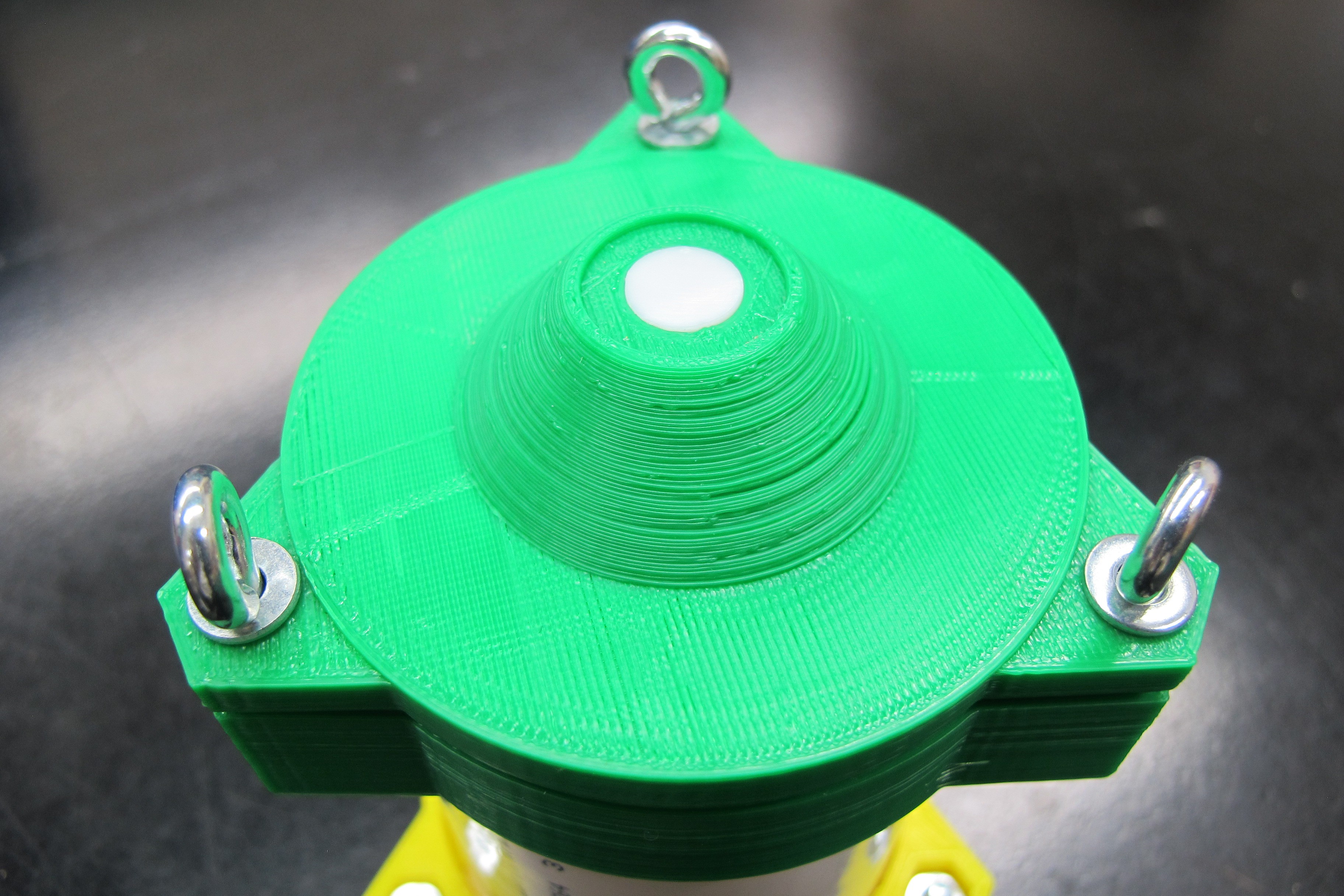

Short log here but as I laid out in the project description my plan is is to use 3D printed parts to build the water proof enclosure for the profiler that will contain all the electronics. The base station, which I have not discussed very much will also built with 3D printed parts and needs to be waterproof as well. Several weeks ago I printed some parts using PLA to do some strength and waterproofing tested. The images below show the collar and cap for the top of the profiler which has an opening for the downwelling irradiance sensor.

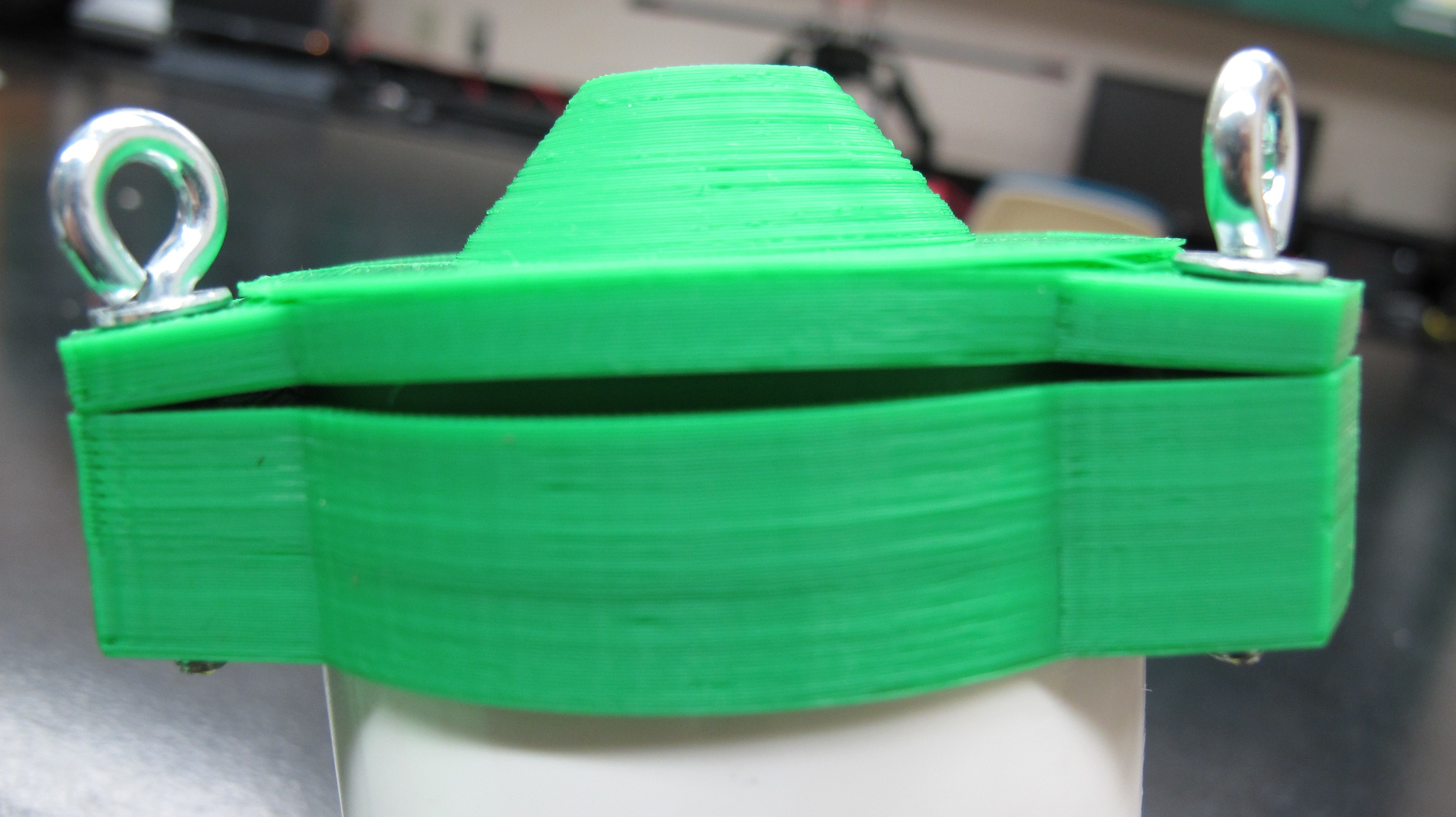

The eye bolts serve two purposes, first to tighten and clamp down against the collar to provide a watertight seal and as tie points for the line used to lower and raise the profiler. As you can seen from the images below the printed part straight off the bed is not strong enough to withstand the force of bolts and washer are putting on it and the layers splits.

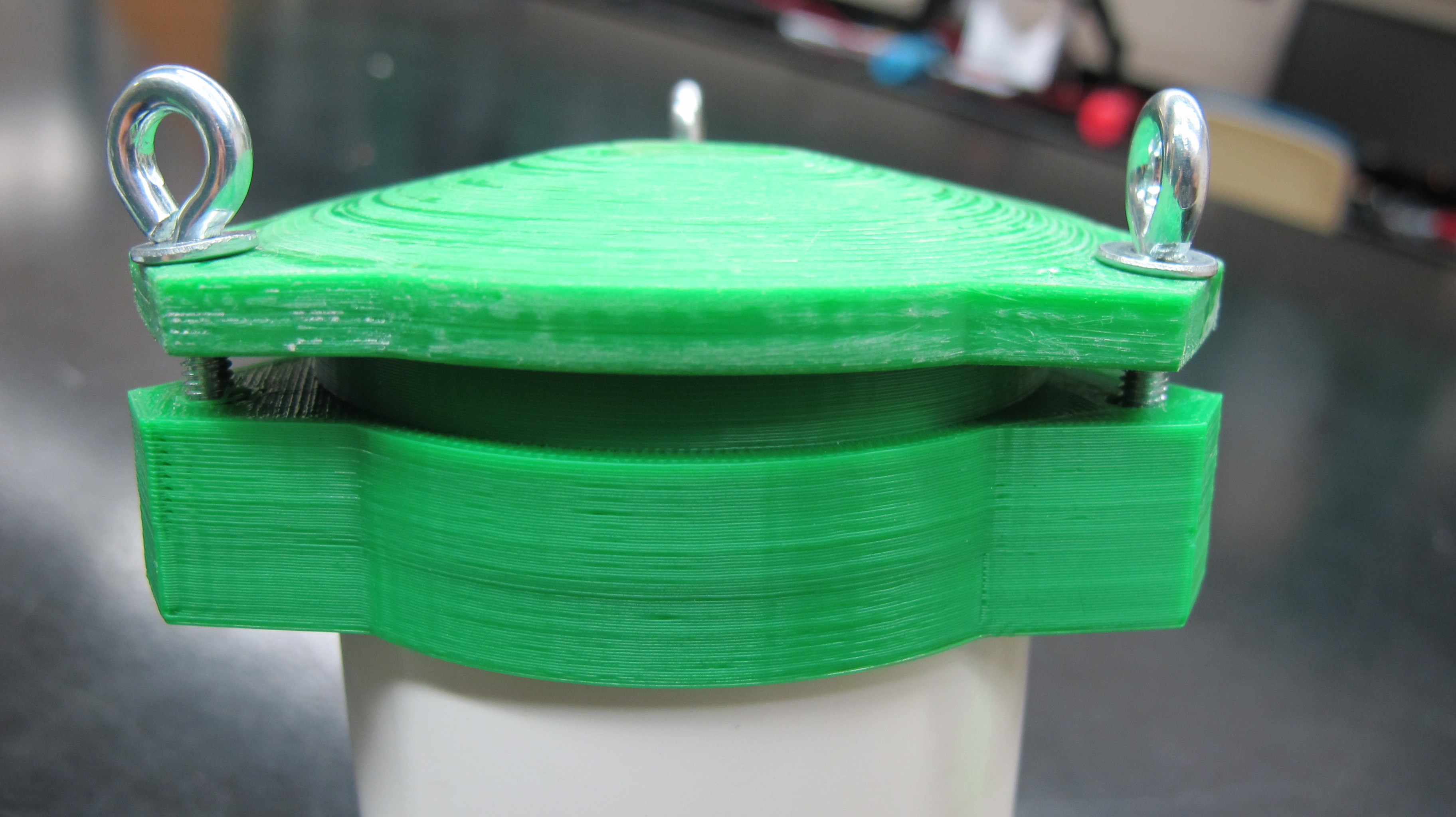

I then tested out a previous version of the cap that I coated in Bondo epoxy resin. It's impossible to tell from the picture below but the bolts were significantly tighter than from the previous test, in fact is was so tight that the collar, which contains the nut that the bolt threads into and was not coated in resin, begin to split.

These tests show promise for the resin coated parts in strengthening the the plastic. More updates on this to come as I continue to design the profiler body.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.