Thermopiles and pyroelectric sensors basically rely on turning the light that hits them into heat and then inferring the laser power by how much the sensor has heated. From a laser *power* point of view this is nice, because they are not that sensitive to what wavelength the light is save for the variation in reflectivity of the sensor.

Photodioes are a bit more tricky. Lasers have a wavelength, and with that wavelength an energy per photon:So the energy per photon is Planck's constant * the speed of light / wavelength.

Photodiodes count photons, not energy.

To get the photon into the photodiode one must couple the light into the semiconductor crystal to have a chance to absorb the light. Some of the incident light will be reflected.

The

amount of a wave that is reflected from any interface between two

materials depends on the impedance mismatch between the two materials.

In optics the typical way to parameterizethe

impedance is the index of refraction. The index of refraction of

silicon is around 3.4, and the index of refraction of air is nominally

1. Fresnel's equations allow

the calculation of how much light will reflect off the surface. To

minimize this problem photodiodes are anti-reflective coated. Light

photovoltaic solar cells this often makes them look blue. The

anti-reflective coating is a thin film that typically is a quarter

wavelength of the wavelength of light the user most cares about.

If the photon goes into the semiconductor that makes up the diode it might get absorbed. The probablity of this increase the larger the energy of the photon. If it is absorbed it creates an electron-hole pair. If that electron-hole pair makes it out of the diode you get some current.

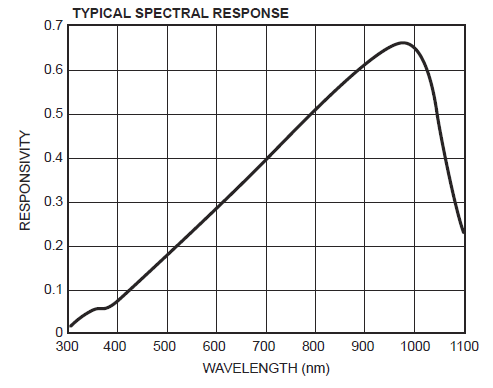

All of these considerations result in a optical response function for a photodiode. A typical response for a silicon photodiode is shown below:

The response above is that of ODD-12W. Which is fairly typical of a silicon photodiode. Different anti-reflective coatings shift this around a bit. The responsivity of the diode is often plotted in A/W, here it is a relative scaling of A/W with respect to a fixed point at 632 nm where they report a typical value of 0.40 A/W.

The function peaks at high wavelength because for each W of power at those wavelengths there are more photons. The silicon meanwhile absorbs them less well, and the reflectance off the surface of the diode changes. These are the three main factors that produce the shape above.

If we want to use a photodiode to measure the power of a laser we must know the responsivity of the photodiode well at that wavelength. This almost certainly mean that the laser power meter will need calibration to be accurate. Although the datasheet's curve will get us close.

The reason I will choose to use a photodiode for this project is mainly because they are easy to work with and inexpensive. The main downsides are this complex responsivity function that requires careful calibration.

The photodiode I have initially settled on is ODD-12W. The characteristics I have looked for in my photodiode are:

(1) Low cost

(2) Large area

(3) Low dark current

The first is self-explanatory. The second is helpful if the laser beam gets large. Commercial power meters look to have photodiodes with diameters on order 6 mm. While these do exist from electronic part suppliers they are substantially more costly, as I result I choose a 4 mm diameter photodiode.

The laser parameter is the dark current. This is the current that the photodiode supplies when it is reversed biased and there is no light. Essentially it is scaling factor in the Shockley equation.

The reason it is important is that it represents a noise level of current that the diode produces. For the ODD-12W the typical value of dark current is 3 nA. This will set a lower bound on our ability to detect the laser power. Near 400 nm the responsivity function is nominally 0.1 A/W. (405 nm diode lasers are common). This implies that we would have a signal to noise ratio of 1 at an input power of nominally 30 nW. A 600 dollar detector (no sensor head) reports a minimum detectable power at 400 nm of 20 nW. So although this is not the lowest dark current photodiode available, it seems reasonable and will be the first detector I will try.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.