Etch-A-Whiteboard

Automated Precision Drawing for the Artistically Impaired

Nate Foss and Alex Hoganson

Automation and Robotics Research Lab

Thomas Jefferson High School for Science and Technology

2015-16

Table of Contents

Abstract 3

Introduction 4

Literature Review 5

Inspiration 5

Hardware Acquisition 5

Methodology and Results 6

Bill of Materials 6

Horizontal Axis 6

Vertical Axis 7

Pen Holder 7

Electronics 8

Code 8

Generating the Instruction File 8

Interpreting the Instruction File 9

Discussion 10

Problems Encountered 10

Broader Application 10

Conclusion 11

Final Comments 11

Resources 12

Appendices 13

- Holistic Visual Documentation 13

- Bill of Materials 14

- Hardware 15

- Electronics 21

G. Image Processing Code 22

H. Image Processing Results 25

I. Movement and Instruction File Reading 26

Abstract

Our project was designed in the context of aiding advanced, large-scale prototyping and drafting work. By creating a machine that can draw large-scale, real-world vectored images from any photograph, our research sought to enhance the artistic ‘skills’ of the average individual. We were inspired to create this drafting aid when we noticed the lack of such a helpful tool, and all the potential uses it could have. This automated drawing tool could revolutionize the classroom setting and change forever the way we make prototypes.

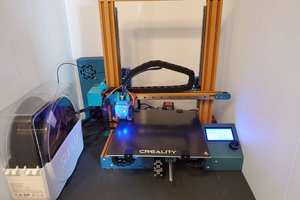

The key to successful implementation of this project was moving the pen around on the board exactly as we wished via the Raspberry Pi’s direction. Taking inspiration from 3D printers and laser cutters, we decided on the two rail system diagramed in figure C.1, with the addition of a pen holder to control if it drew when it moved or not. The two axes were horizontal, across the top of the whiteboard, and vertical, which moved across the board and moved the pen holder up and down it. The final product closely matches the diagram, and can be seen in figure C.2.

To accomplish this, the Etch-A-Whiteboard used sophisticated edge detection algorithms in conjunction with precise DC stepper motors. While constructing the Etch-A-Whiteboard, many problems were encountered and subsequently solved. Complications that were solved included unnecessarily heavy components, stepper motors with insufficient torque, large 3D printer tolerances, power supply problems, and analog linear actuator control mechanisms. However, the large time buffers built into the project during the design phase allowed these challenges to be overcome and still complete the Etch-A-Whiteboard on time.

The project terminated in a satisfactory state of functionality. The Etch-A-Whiteboard accurately renders instruction files to trace the edges of images with precise lines. Persistent problems included heat dissipation and logic voltage discrepancies.

Introduction

Our project was designed in the context of aiding advanced, large-scale prototyping and drafting work. By creating a machine that can draw large-scale, real-world vectored images from any photograph, our research sought to enhance the artistic ‘skills’ of the average individual. We were inspired to create this drafting aid when we noticed the lack of such a helpful tool, and all the potential uses it could have. This automated drawing tool could revolutionize the classroom setting and change forever the way we make prototypes.

Applications for this technology are many and varied. Its potential use in the classroom cannot be overstated. For example, envision an electronics professor who draws a circuitry diagram for his students. Although the diagram is well-made and understandable, it’s hand-drawn, and impossible for all his students to see at once. He could take a photo, and project it for his classroom- but that leaves his diagram unmalleable and static. But with such an automated drawing machine, he could perfectly reproduce that diagram on the whiteboard and chalkboard, yet still leave it open to editing, allowing everyone to study and learn optimally.

Similarly, consider a photo or diagram that’s simply too complicated for...

Read more »

g0ldenerd

g0ldenerd

John Opsahl

John Opsahl

Aaed Musa

Aaed Musa

Greg Duckworth

Greg Duckworth