The Houston Mini Maker Faire last weekend went well. Thanks to everyone who stopped by. We spend the entire time answering questions. I was amazed at how many Hackaday readers came by and said hi. We have some pictures from the event here. If you have any pictures, we'd love to see them. Houston Mini Maker Faire

Another thing I've been working on is documentation on the propellers. I'd struggled during The Hackaday Prize on how best to document the propellers as part of Goliath. I finally decided that the best way was simply to have a separate project log for the propellers. So if you're looking for details on the propellers, check out Inexpensive Composite Propellers/Rotors (Project 3221). Like Goliath it's still a work in progress.

Now that I don't have the time crunch with The Hackaday Prize, I can take take a bit more time to fix some things. One thing I'd been meaning to fix was the starboard exhaust pipe. I'd initially made a mistake welding it together and placed it on the wrong side of the bracket. Later the problem was compounded when I lowered the engine an inch. This made it more obvious that there is a height difference between the two cylinders (3/4" to be exact). This made it so that the starboard exhaust pipe vibrates against the frame when running the engine, something that should be taken care of before I run the engine too much more.

To fix this I ground off the old weld, cut 3/4" off the pipe and tacked the flange back on. I tripled check the fit this time, finished the weld and I'm in the process of repainting the exhaust.

The pulleys have been reconfigured by replacing one of the toothed idlers with a flat belt idler. This is a nylon pulley instead of steel, it's lighter, but I'm not 100% confident it's really going to work well, but that's what testing is for. If this doesn't work I'm going to have to see about making some custom idler pulleys.

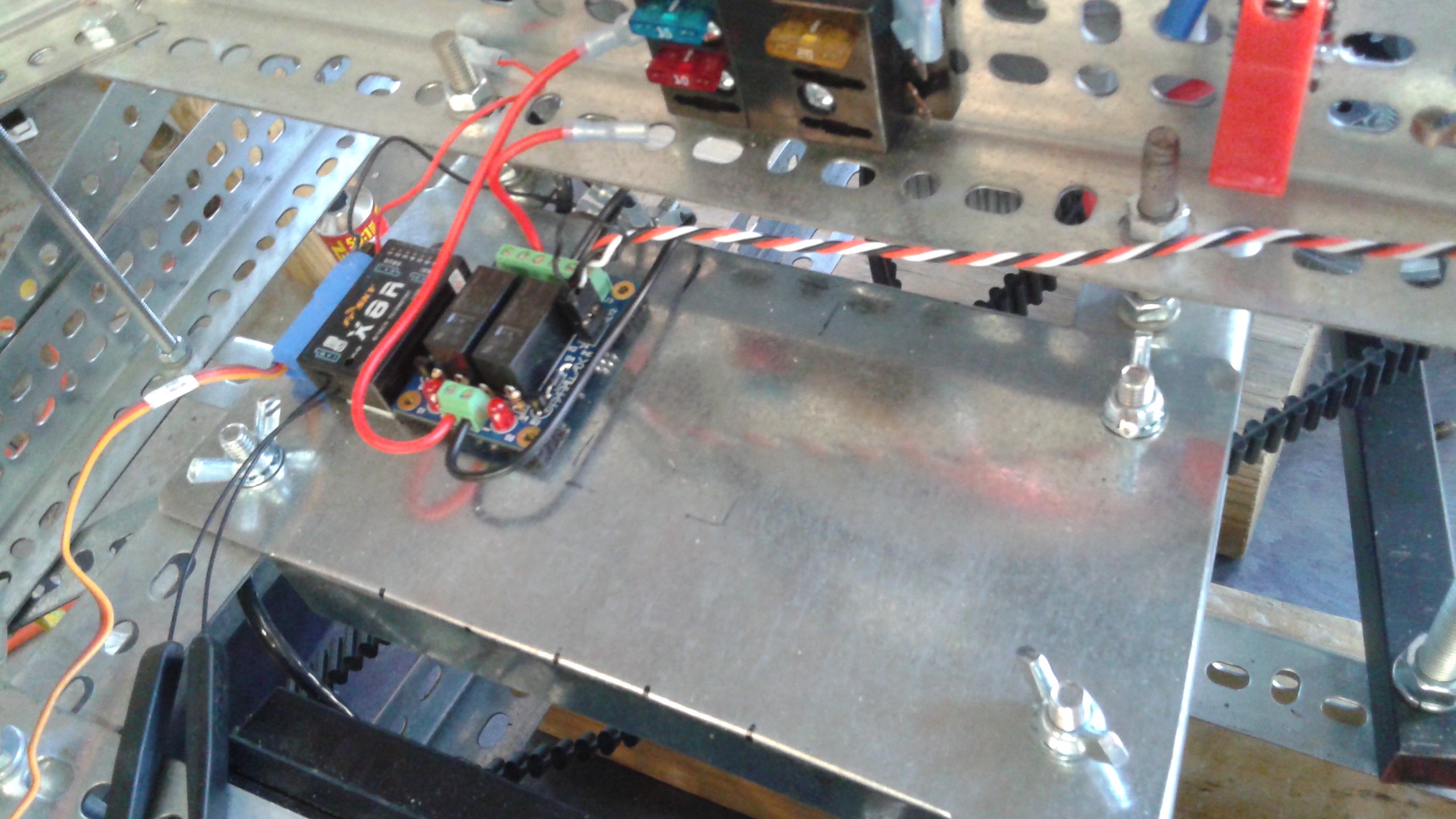

The other items I've been working on getting ready for the next test are the relays. I've added an electronics tray made of of thin galvanized steel and mounted using wing nuts. They are some neoprene washers to help dampen out vibration. I've started mounting some of the electronics using double sided tape, but I need to do some rearrangement. So far the receiver, relay board and BEC are mounted. The Pixhawk will mount on the center, below the fuse box.

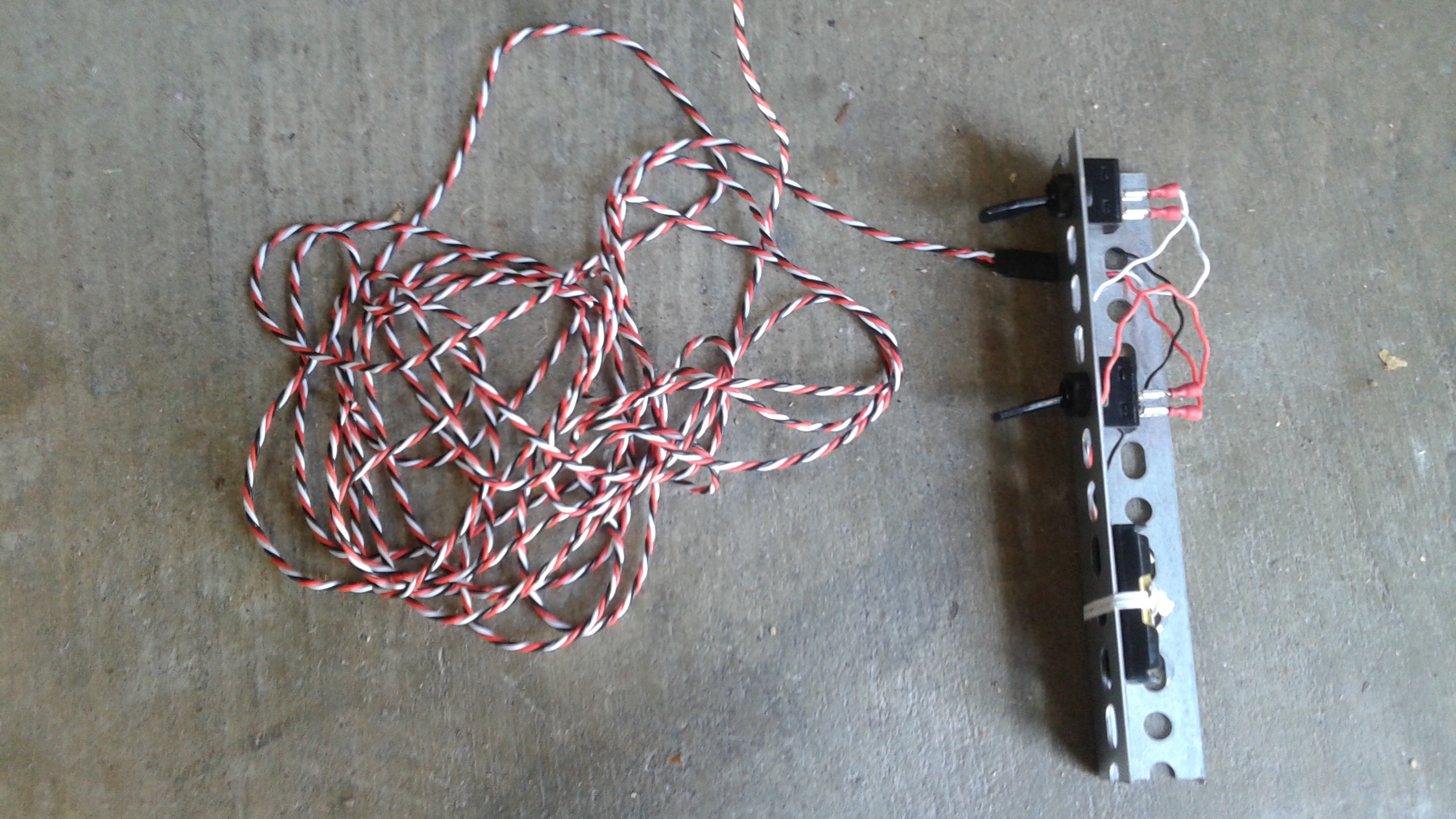

Since I don't have the software yet for the Pixhawk, and the relays can't be control directly through the RC receiver directly, I've created a wired remote for the relays. The remote has an on/off switch for the ignition and a momentary switch for the starter relay. The remote has 3 AAA batteries to supply 4.5V to the relays (they will take 3.3-5V ). I'd ordered 25 ft rolls of servo wire to make custom harnesses so I used on of these rolls to carry the signals until the controller is ready.

Once I get all these items finished up and the vehicle is back together, it'll be back to testing.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.