Thrust measurement and weight reduction has been the focus of the work on Goliath over the last few weeks. Prior to the last test, Goliath weighed 238 lbs, about 40 lbs more than the target weight when the project started. With the vehicle design still in flux it's not time to move away from the slotted angle yet, but there were a few areas that could provide some potential weight reduction.

Bolts and Washers

When Goliath being assembled for the first time, the final design was somewhat nebulous. To make things easier, the same sized bolts where used for the frame assembly. Most of the bolts don't need to be the full length, so wherever possible, the original 3/4" long bolts have been replaced with 1/2" long bolts. The size difference is shown below. About 75 of these bolts have been changed out for smaller bolts

While the bolts were being swapped out, the traditional lock washers where replace with external toothed lock washers. The primary reason for replacing the washers is that the traditional lock washers aren't very vibration resistant and every test would see at least one or two come loose. A bonus to replacing the washers is that the external tooth washers are lighter than the traditional lock washers. The picture above also shows the external toothed and traditional lock washers.

Cross Beams and Side Beams

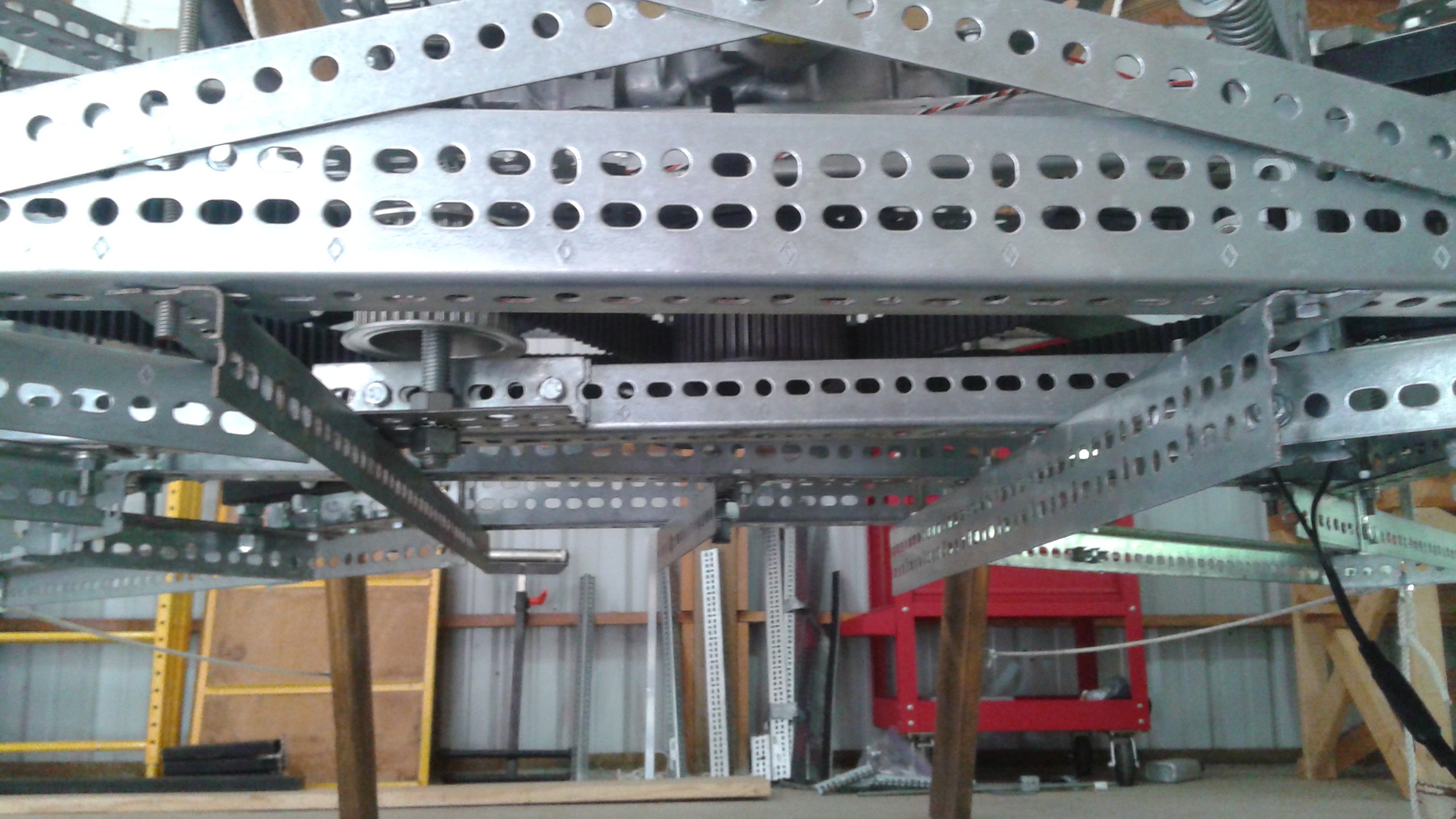

The side and cross beams previously used the wide slotted angle. It was felt that they could be swapped out for the narrow slotted angle with a minimal reduction in stiffness. Below on the right is the wide cross beam and on the left is the narrow cross beam replacement installed.

Cross Members

The cross members were another area improved. Previously the two cross members on each side of Goliath spanned the whole length of the side and angle wasn't ideal for stiffness. Each of the cross members where removed and trimmed into two smaller pieces, with a little bit of excess. These pieces where then used to form two smaller crosses on each side. Below is a shot of the side beams and cross members being reconfigured on one side of the vehicle.

After completing the structure modifications, the end result is that Goliath looks a bit leaner, and the weight was reduced by 5 lbs to a total weight of 233 lbs. The slotted angle structure is probably as lean as it's going to get.

Propeller Axles

Another issue that needed to be addressed was the axles for the two propellers powered by the double sided belt. After inspecting the vehicle it was found that the axles were slightly deformed (see picture below). The double sided belt needs additional tension, probably because of the extra length and the difference in the angles. Eventually the all-thread axles will be replaced with thicker axles, but for now an easy fix was to replace the 5/8" zinc plated all thread rod with 5/8" stainless all thread rod. The stainless has a higher strength and has more resistance to being deformed.

Thrust Measurement

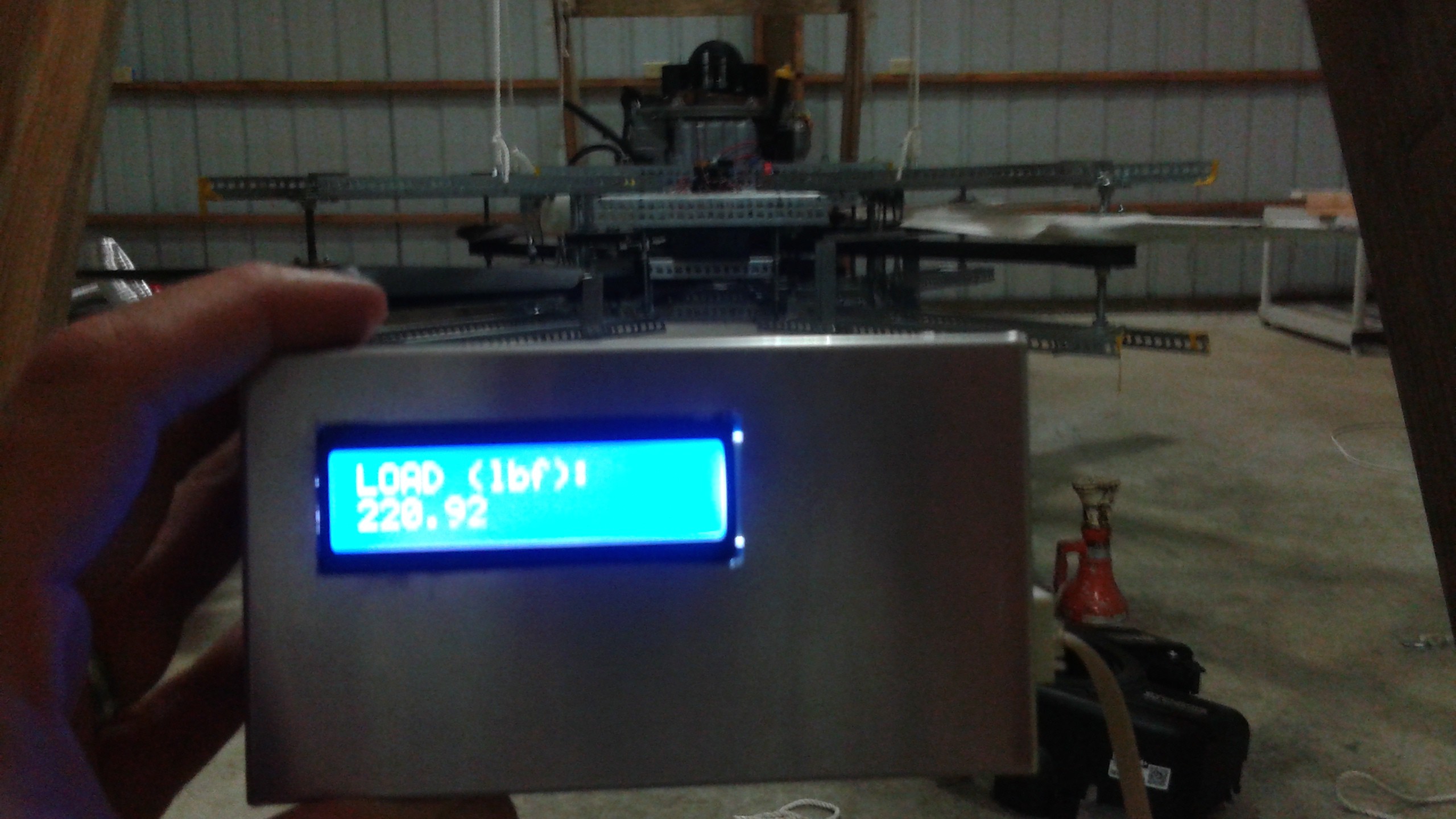

The thrust measurement portion of the # Drone Test Stand has been completed. You can read the details there, but the test stand has been setup to measure the thrust while Goliath is running. Below is a picture of the remote display with Goliath in the background.

In the above picture the reading says 220.92 lbs. This was because some of the hardware had been removed from Goliath. Note that there is no data logging capabilities built it. The measurements are being recorded visually for now.

Testing

Three more tests have been conducted since the last posted test. There hasn't been time to compile the video yet, it'll probably get posted over the weekend.

Test 22 tested the latest changes in the frame. The test went smoothly and Goliath was brought up to full speed without the ignition switch coming loose. There was no flexing in the frame visually, so the new design appears to be working.

Test 23 attempted to get full thrust measurement data. However the double sided belt tensioner was not performing satisfactorily and the engine speed was limited to 25%. The thrust measured at 25% throttle was approximately 70 lbs.

Test 24 was performed after a redesign of the tensioner, the details of which will be posted in a later project log. This time the tensioner worked and Goliath was able to get to 100% throttle. The recorded load at full throttle was 31 lbs, but the readings were 11% low at the start of the run. Accounting for this offset the actual load is closer to 35 lbs at full throttle and the total thrust was (232 lbs - 35 lbs) = 197 lbs.

While there isn't any corresponding RPM data. The data corroborates what the latest analysis suggested.

As @Smerfj pointed out in a comment on my last point. The issue is really an RPM mismatch. Here's a quote from his comment:

"If you need all 30 Hp to lift, the engine must run at 3600 rpm and the current prop must run at 2700 rpm. So you need a pulley that allows the motor to run at a speed ratio of 3600:2700 or 4:3."

[Edit: @Smerfj noted I made an error here. The ratio he was referring to above is the speed ratio and the pulley ratio is the inverse. This means that the propeller pulleys need to be larger than the main pulleys to get them to the right speed]

The current pulley ratio is 10:11, to change the ratio either the propeller pulleys need to be made larger or the main pulley needs to be smaller. All of the pulleys are as small as they can be without risking the belts skipping teeth. Larger propeller pulleys could be used and it would provide more area for torque transfer, but bigger means heavier. Larger pulleys would also require changes to the entire belt layout. Redesigning the propellers requires some work, but no other reconfiguration would be required.

The next step will be completing a new propeller design and then making a new set of propellers.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The ratio I noted is the speed ratio, which is inverse of the pulley ratio.

Are you sure? yes | no

Good catch on both. Yes that makes sense

Are you sure? yes | no

Careful! You got the pulley sizes backwards. You need the motor to run faster than the props, 4:3 :: Motor:props - so the motor pulley gets smaller or the prop pulleys larger.

Are you sure? yes | no