Progress

All of the new rotor pulleys have been installed and have been tested for a cumulative run time of 20 mins. (The video has yet to be edited together).) The great news is that there have been no occurrences of rotor bolts breaking and the new hardware is significantly lighter. For the last full power test (#21) the vehicle weighed 238 lbs. For the latest tests, the vehicle is now down to 213.8 lbs.

This was mostly due to switching to the aluminum rotor pulleys, but some additional weight reduction came from trimming off the excess material for the arms supporting the rotors. Here's a shot of the vehicle in its current configuration.

The excess length had been left on in case the rotor pulleys needed to be shifted outboard. Now that the design has had time to mature, the likelihood of moving the arms outboard seems low. There is still sufficient clearance to increase the prop diameter easily up to 40 inches if needed.

Tension Issues

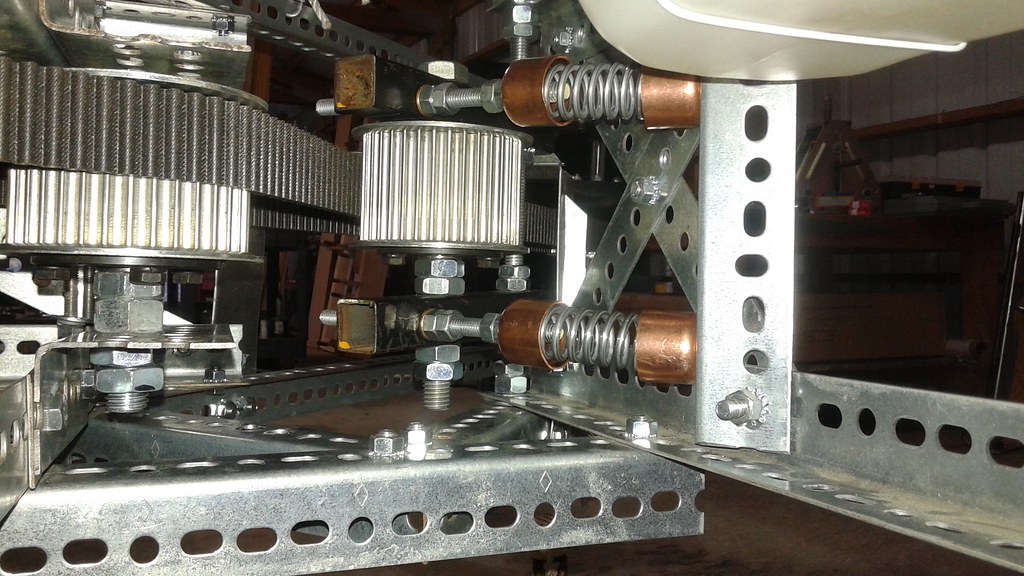

The tension on the single sided belt is just right. The teeth haven't skipped and the tensioner hasn't had to be readjusted for the last 10 minutes of testing. This is due to improvements made to the tensioners. Prior to the changes, the all thread that holds the springs in place would sometimes bind up where it passes through the structure supporting it. The fix was to hold the spring captive with end caps fashioned from copper pipe caps. Below is the latest iteration of the double sided belt tensioner. This design also helps by allowing for a small degree of misalignment, allowing the tensioner assembly to rotate freely.

Getting the tension correct on the double sided belt has been more problematic. The teeth occasionally skip on the double sided belt, particularly when the engine decelerates and more slack builds up. Several different tensioner configurations have been tried and none of them have completely solved the problem yet. The latest configuration appears to be promising, but fixing the tensioner has been put on hold since some engine issues have developed.

Getting the tension correct on the double sided belt has been more problematic. The teeth occasionally skip on the double sided belt, particularly when the engine decelerates and more slack builds up. Several different tensioner configurations have been tried and none of them have completely solved the problem yet. The latest configuration appears to be promising, but fixing the tensioner has been put on hold since some engine issues have developed.

Engine Issues

In the twenty minutes of testing after all of the the new rotor pulleys were installed, the engine runs reasonably at idle. However, when the throttle is increased, the engine appears to bog down and the RPM does not increase. Part of the problem could be the tension issues with the double sided belt. However, the tensioners haven't been completely right in the past and the vehicle was able to get up to higher RPMs. The first sign that something else was wrong showed on the exhaust pipes. In the picture below there is a visible difference between the two exhaust pipes, with liquid present on the starboard exhaust pipe.

At first glance it looked like oil, but upon closer inspection it appears to be mostly gas and soot. The spark plug on the starboard side was examined and it, too, was covered in a gas/soot mixture, which likely means the cylinder isn't firing. Below is a picture of the spark plug from the suspect cylinder.

At first glance it looked like oil, but upon closer inspection it appears to be mostly gas and soot. The spark plug on the starboard side was examined and it, too, was covered in a gas/soot mixture, which likely means the cylinder isn't firing. Below is a picture of the spark plug from the suspect cylinder.

For comparison, here's a picture of the spark plug from the port cylinder that appears to be running fine

For comparison, here's a picture of the spark plug from the port cylinder that appears to be running fine

It's not clear yet why the cylinder isn't firing. The next step is to do some additional troubleshooting. Once the cylinder is firing again, the tensioner issue can be addressed. It could be that the engine running rough on one cylinder could be the cause for the double sided belt skipping teeth. Either way, once both of those issues are resolved, then the next full throttle test can be performed.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.