During the most recent tests, Goliath exhibited more vibration than was seen in earlier tests. After closer examination, it became apparent that the starboard cylinder was not firing. Test 41, when the axle broke, was an attempt to see if the engine had been fixed. Due to the vibration present during Test 41, the starboard cylinder was still not firing.

The usual suspects to check for with a small engine is compression (air), fuel, and spark. There was obviously fuel getting to the cylinder since it's coming out the exhaust pipe. Spark was testing by removing the plugs, resting the ground side against the engine and running the starter. Both cylinders showed good spark. The last test was a compression test. Briggs and Stratton doesn't state minimum compression values, just that both cylinders should be tested and that they should come out the same.

So with all those items checked out, it was quite puzzling as to what the real issue was. I took a trip to a local small engine shop to get some help. It was the right place to go because the guy there gave me great help. He suggested two possibilities. The first was to check the value clearances, that perhaps the hardware holding the values in place had come loose. The second possibility was that there was a bad diode connected to one of the ignition coil.

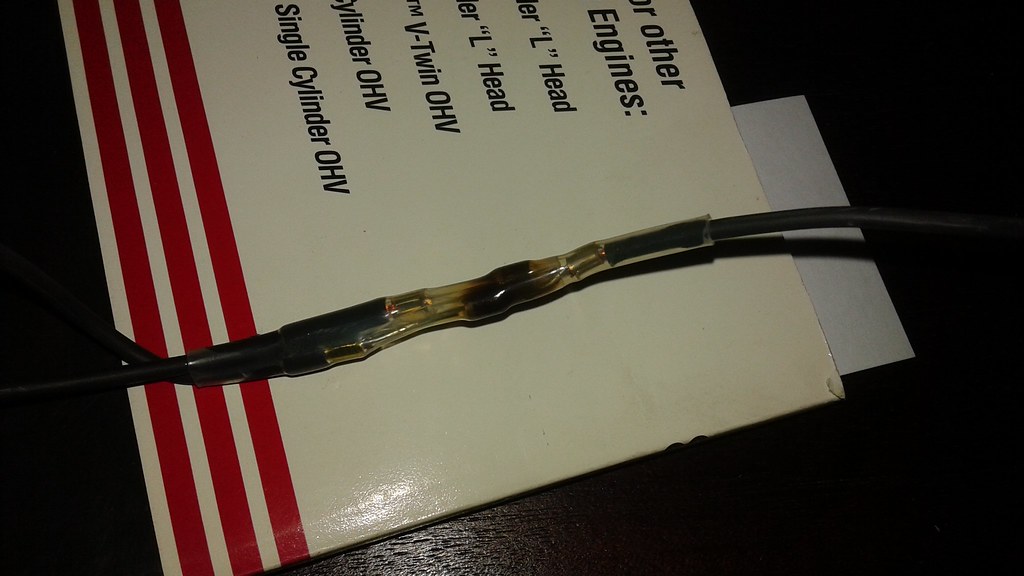

The valves checked out ok, so the diode was the next thing to check out. What's makes this particularly difficult, is that there is no documentation provided by Briggs and Stratton on these diodes expect for the repair manuals, which are difficult to come by. After removing the wire harness it was very obvious that the starboard diode was failed.

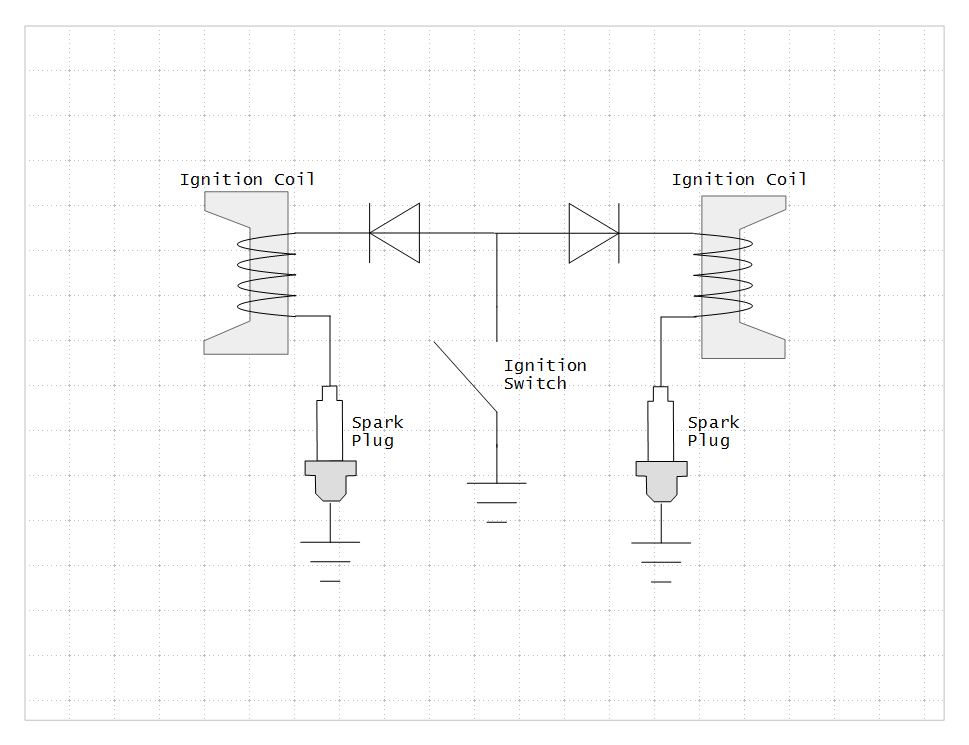

The failure modes are pretty interesting. The ignition switch works by grounding the ignition coils. The diodes act as a bridge to isolate the two coils from each other. When one of the diodes fail closed, the coil it's connected is no longer isolated from the other coil. When the other coil fires, it grounds the coil connected to the failed diode, preventing it from firing. This was precisely what happened on Goliath.

The failure modes are pretty interesting. The ignition switch works by grounding the ignition coils. The diodes act as a bridge to isolate the two coils from each other. When one of the diodes fail closed, the coil it's connected is no longer isolated from the other coil. When the other coil fires, it grounds the coil connected to the failed diode, preventing it from firing. This was precisely what happened on Goliath.

With the cause identified, the next step was to repair the wire harness with the diodes. The diodes are potted in a clear plastic, so the failed diode was visible through the coating. It was difficult to get a good shot up close to show the charring.

Typically the wire harness is replaced as a whole, is specific to the engine make and model and has to be special ordered. Instead the harness was torn down and the diodes part numbers were identified (IN4007). This is was simply a matter of getting the diodes from Radioshack and soldering the harness back together.

The new hardware to repair Goliath with is in the process of being built, so the engine was tested with just a single belt and one pair of rotors to ensure that the engine was indeed fixed.

The new hardware to repair Goliath with is in the process of being built, so the engine was tested with just a single belt and one pair of rotors to ensure that the engine was indeed fixed.

The test was a success. Both cylinders are firing and the engine now runs much smoother. The increase in power is also clearly visible, with Goliath lifting up the one side with the two rotors. Looking at the video in slow motion, it's clear that one of the tethers reached it's full extension.

After the new hardware is complete, Goliath can be fully reassembled and further testing can be conducted.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Glad you figured it out. Annoying that B&S doesn't make that an easy problem to diagnose.

Are you sure? yes | no

With the diode failed, why did both spark plugs work when you initially tested them?

Are you sure? yes | no

My understanding is that at low speeds, like just running the starter, the timing between the two ignition events is far enough apart that it isn't an issue. Once the engine is running faster, then it becomes an issue.

Are you sure? yes | no