I'd hoped to be well into working on the controls on Goliath by now, but the shorter days and colder weather mean less time in the shop. I'm still nailing down some lingering issues with the drive train. The new pulleys are weeping grease because the bearings are getting too hot. I suspect it's because I'm using all thread axles and nuts to keep the bearings in place. I'm working on building the proper axles and axles mounts to go with the new pulleys.

Meanwhile I wanted to document the progress made on mitigating the vibrations that the avionics experience. This was accomplished by better isolating the engine from the frame and the avionics tray from the frame. The new engine mounts are made primarily of rubber, but are built such that if the rubber fails, the bolts are still captive. Stainless steel bolts are used to attach the mounts.

Meanwhile I wanted to document the progress made on mitigating the vibrations that the avionics experience. This was accomplished by better isolating the engine from the frame and the avionics tray from the frame. The new engine mounts are made primarily of rubber, but are built such that if the rubber fails, the bolts are still captive. Stainless steel bolts are used to attach the mounts.

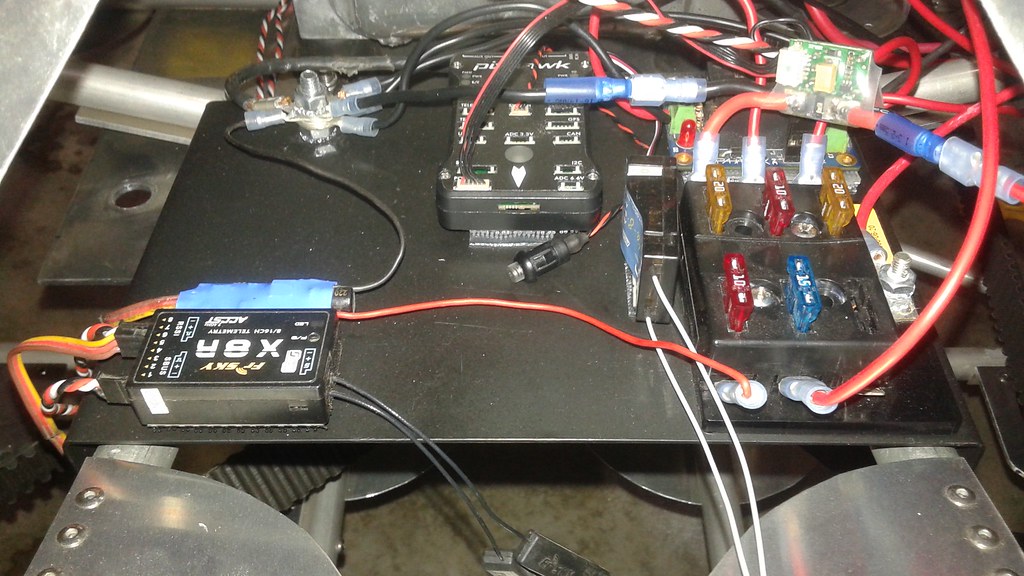

The avionics tray was switched from aluminum to steel. This was to add mass to help reduce the displacement of the avionics tray. Below is the new tray with some of the avionics populated.

The avionics tray was switched from aluminum to steel. This was to add mass to help reduce the displacement of the avionics tray. Below is the new tray with some of the avionics populated.

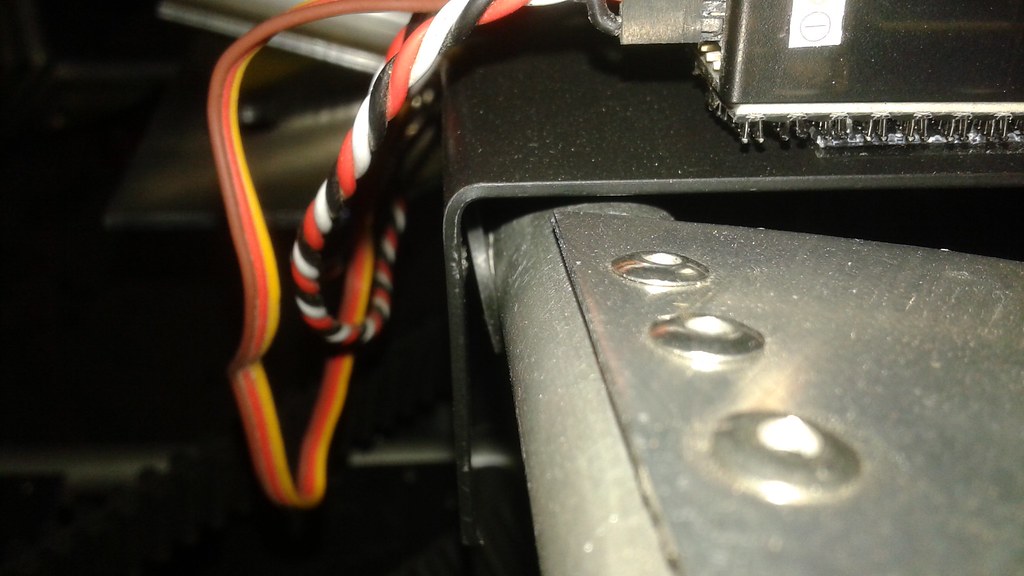

The tray is mounted to the frame using four Expansion Nuts. I forgot to take a picture of them before I installed them, so here is a link. Below is a shot showing the flange on the expansion nut between the tray and the frame.

The tray is mounted to the frame using four Expansion Nuts. I forgot to take a picture of them before I installed them, so here is a link. Below is a shot showing the flange on the expansion nut between the tray and the frame.

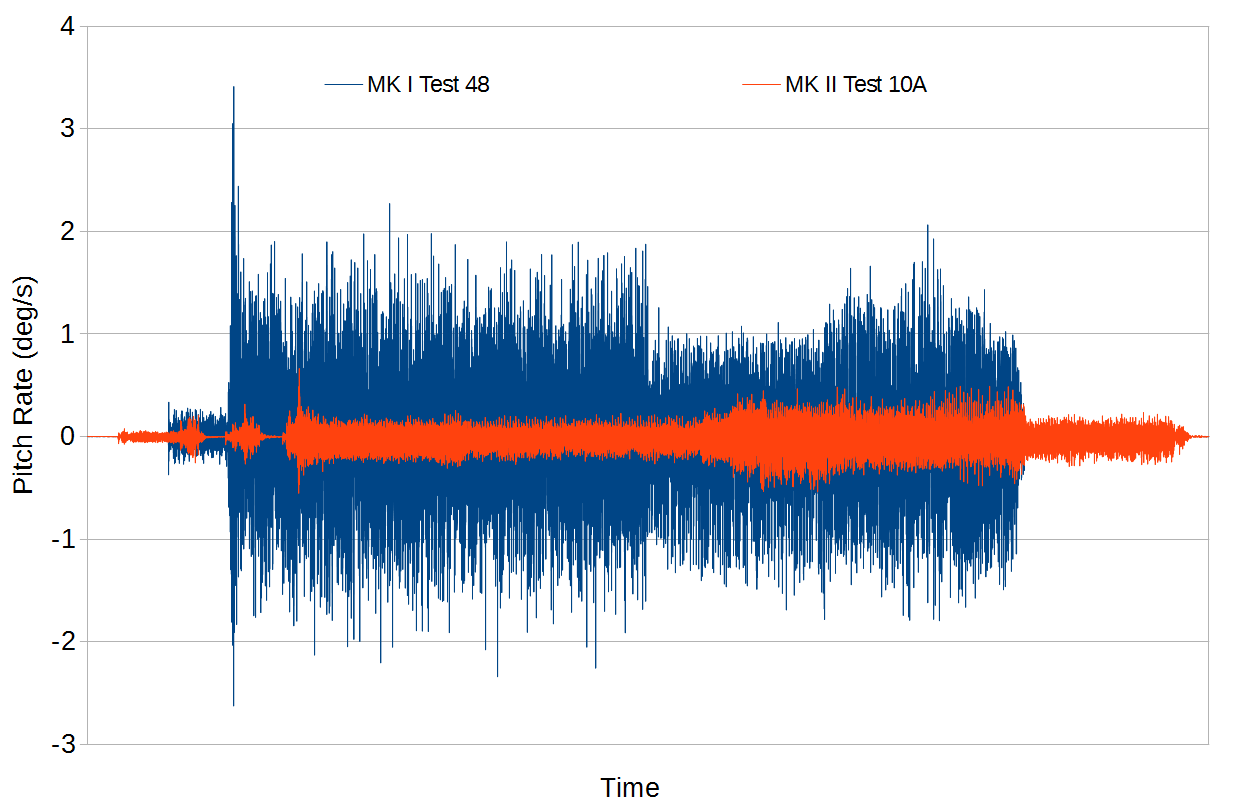

So how much did all the changes help? Data from the Pixhawk shows a huge reduction in the pitch rates down by a factor of 5 to 10. This means that the Pixhawk should be able to control Goliath once the rest of the hardware is complete.

So how much did all the changes help? Data from the Pixhawk shows a huge reduction in the pitch rates down by a factor of 5 to 10. This means that the Pixhawk should be able to control Goliath once the rest of the hardware is complete.

Hopefully the next log update in the not too distant future will be about fixing the bearing issues.

Hopefully the next log update in the not too distant future will be about fixing the bearing issues.

Peter McCloud

Peter McCloud

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.