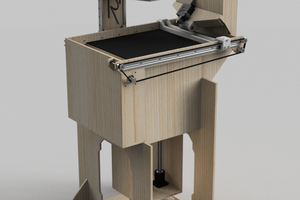

Not only any 3D printer but also any DIY Engraver will fit for it

or a constructor of a makeblock plotter xy type

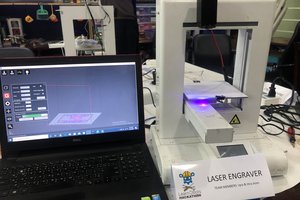

By the way, you can install a diode laser almost on any 3D-printer, setting it as an addition or in place of the extruder. Diode lasers are small in size and compact. Their relatively small power output compared with that of CO2 lasers is not a drawback in this case.

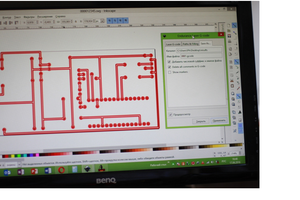

So, what does the process of the circuit board manufacturing at home or in the office look like?

For this we need a copperized glass fiber plate, any dark vinyl film (any dark film that a laser can burn through will fit), iron chloride (sold openly in stores of chemical reagents) and, of course, a diode laser installed on a 3D printer. Its power output is not so very important, but we recommend to use a diode laser of more than 2W (2000 mW).

To install a laser on any 3D printer is very easy …

How to install it on an Ultimaker https://www.youtube.com/watch?v=soYh5Kyv4cs

and on a WanHao DuPlicator i3 https://www.youtube.com/watch?v=yf-uFAynGhM

So, let’s begin. Go to instructions!

Sergey Mironov

Sergey Mironov

mx3designs

mx3designs

Oliveira

Oliveira

Is your "vinyl film" made of PVC (polyvinyl chloride)? PVC is probably the best-known material for not being safe to laser-cut, because it produces chlorine gas that's bad for both you and the machine.

However, I have seen a video on YouTube (from Jeri Ellsworth, I think) of a fume hood that goes directly on top of the material, with a window for the laser beam to shine through, that captures the chlorine gas, making it safer to cut/etch PVC.