This is a dust separator. We make it using two buckets :

-one for the cyclone part, that we modify to add holes and parts,

-one for the dust bin, that is unmodified.

The idea is to reduce the amount of labor required to make a functionnal and sturdy cyclone.

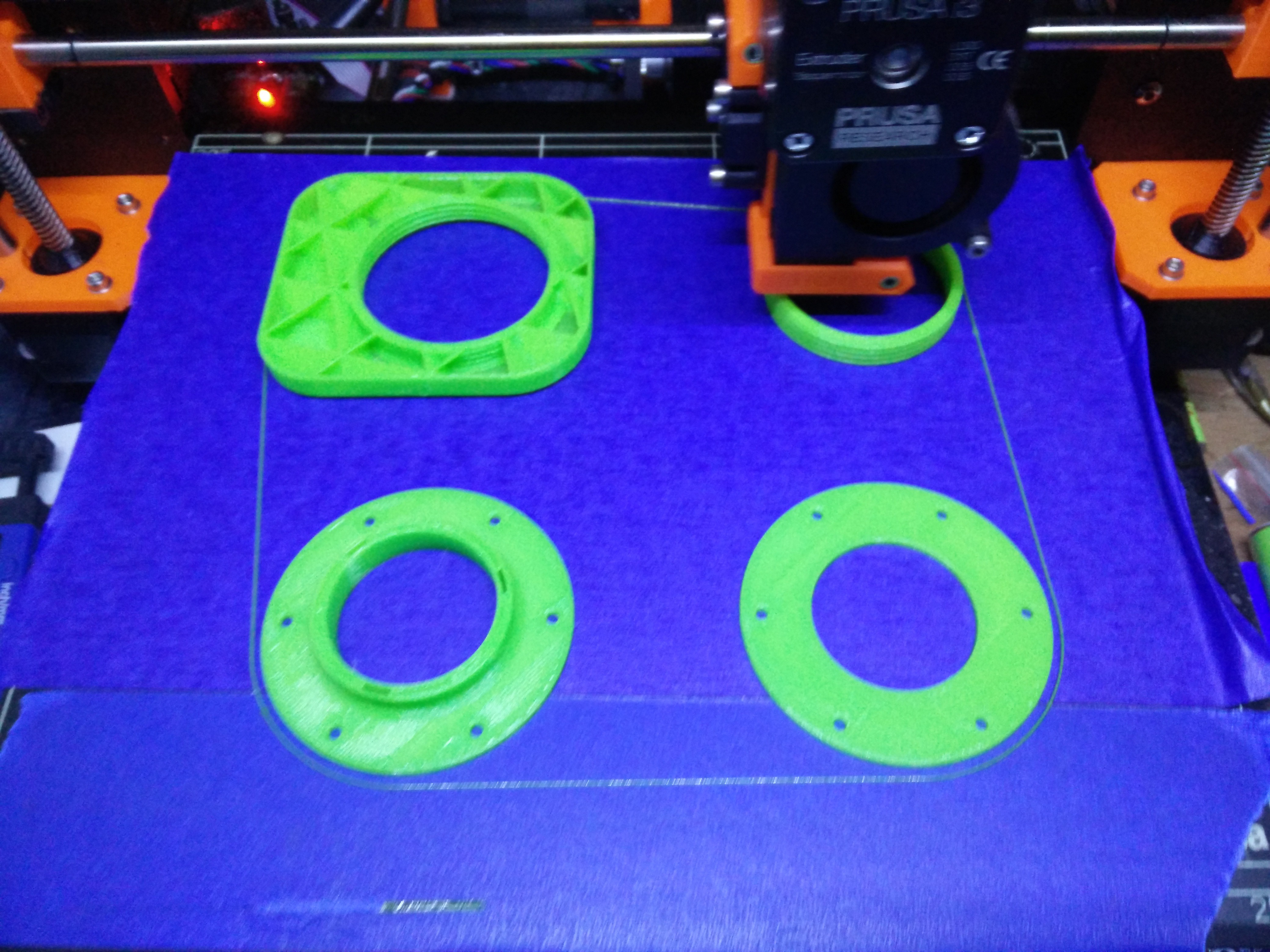

To do so, we rely on 3D printing to obtain the inlet and outlet of the system, and use integrated threads in the model to have a removable inlet hose, and/or create another inlet fitting for another size of hose.

The outlet also have a thread on, so you can design and 3D print an adapter for many vacuum cleaner hoses/pipes.

I created a GitHub repository containing all the STL files to make this, but the fusion360 source file is also there if you want to tweak things.

In this version, the thread specification is marked on the part, so you can simply design adapters for it without having to open the fusion360 file, or within another software.

I would have preferred to provide an openscad file, but i don't know how to generate threads with OpenScad, and i have not yet learned how to use freeCad.

Anyway, for now, you have the basis, you may just have to adjust the inlet and outlet to your pipe sizes or use/make adapters.

Everything is released under the GNU GPL licence, so enjoy :)

Audrey Robinel

Audrey Robinel

Scott

Scott

Grégoire Passault

Grégoire Passault

Alan Campbell

Alan Campbell

Awwww lol, brilliant :-D