In the processing of DNA, RNA, proteins and all the other parts of a living organism, for which we as scientists concern ourselves there is frequently a need to move or process the materials under study. Lets suppose one wishes to digest some DNA using a restriction enzyme. Typically, some DNA would be pipetted into some appropriately sized container, and another bit of enzyme pipetted from another container and the two mixed, etc. Then after awhile, the results of the reaction are pipetted into a well of a gel made up of agarose or an acrylic "PAGE", and the gel is "run" using a high voltage. 400 Volts is certainly typical.

While many might view electrophoresis as a mechanism for sorting out DNA it is more fundamentally a "prime mover". It's as if a river is flowing an you can float your boat and let the current take you down stream. If you can steer your inner tube, canoe, row boat, or yacht, then can take it to the ocean if that's your objective.

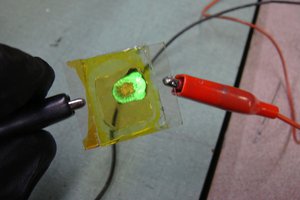

This project is about making a rudder that allows one direct electrophoretic flow in a controlled direction. The first step is to reliably detect what's in the water. The problem is of course that's there a lot more in the river than what's on the surface. There can be no satisfaction in only being able to detect just canoes. If this part of the river can't sort out the fish from the algae, there is another section down stream, two locks left, and one tributary right expressly designed for that function.

From an engineering perspective the view is a bit different. Normally, electronics and water don't mix. Even worse, biological fluids and those fluids used to process biologicals are loaded with salts. Further, the electronics and fluids are by necessity intimate.

There are a vast collection of physical effects that may be exploited for the detection of substances. So many that we may become overwhelmed by our options. Our design options are greatly expanded however if we utilize methods that by default are immune to the effects of water, salts, and basic incompatibilities inherent in conventional technologies. There is of course on technology that offers a solution. It is called LTCC.

Chuck Glasser

Chuck Glasser

Ian Hanschen

Ian Hanschen

bryan.lowder

bryan.lowder

Matthew Borgatti

Matthew Borgatti

Engin

Engin