Having built the Mk1 Munching Engine I couldn't wait to feed it its first taste of green green grass.

At first it cut the grass well but then...

About 8 seconds in you can hear the motor crack the D profile out of the 3D printed shaft. I was worried the print wouldn't be strong enough! However the good news is that prior to breaking the motor happily mowed grass using just a 9V PP3 battery. Also the area I cut looked cleanly mowed and undamaged, so really a few positives to take away.

I wasn't about to stop there though! After all the prototype now has a taste for the green stuff.

The shaft rounded its D profile so I would have to come up with a more positive engagement; I had an unlikely idea... a grub screw.

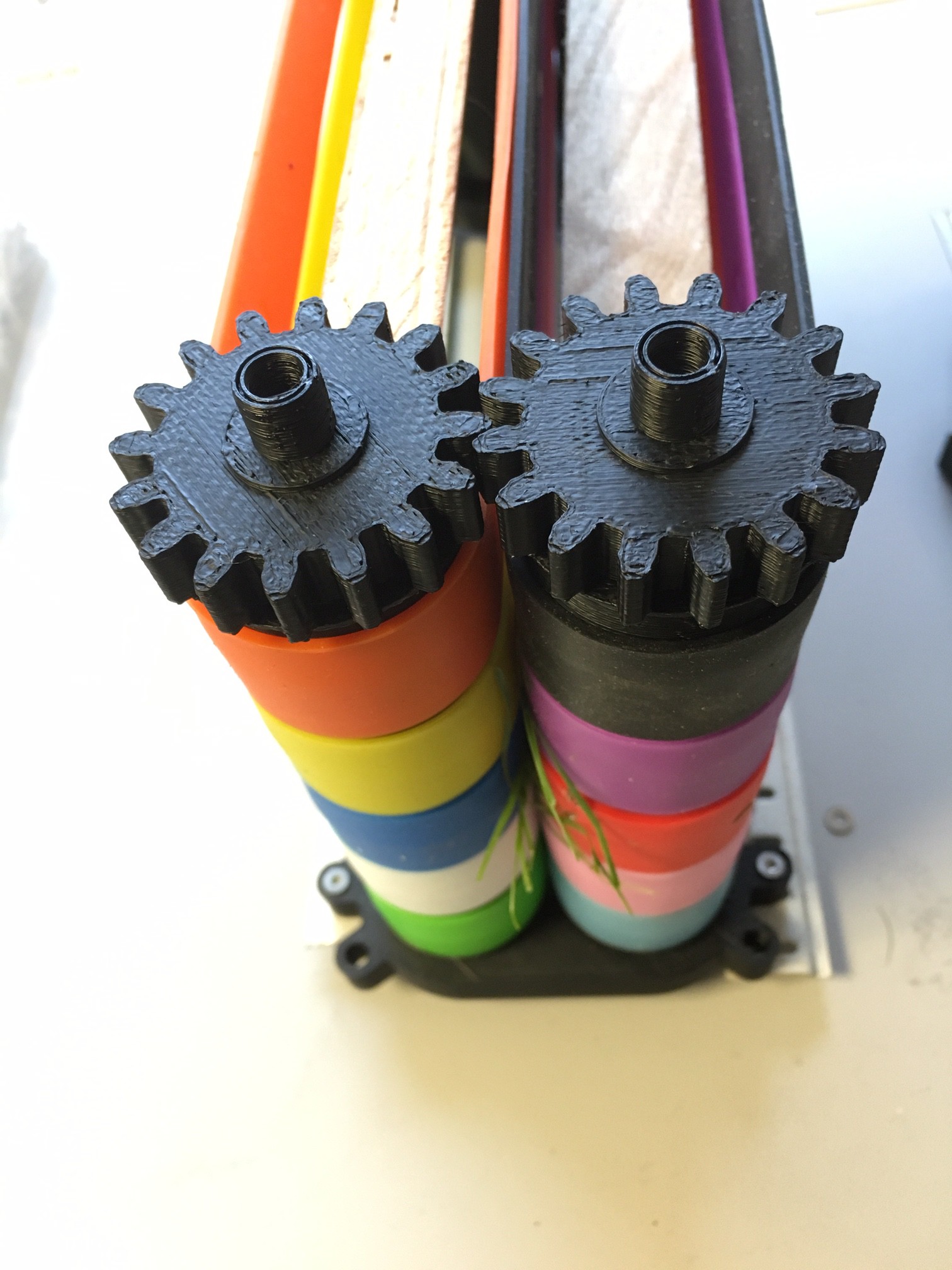

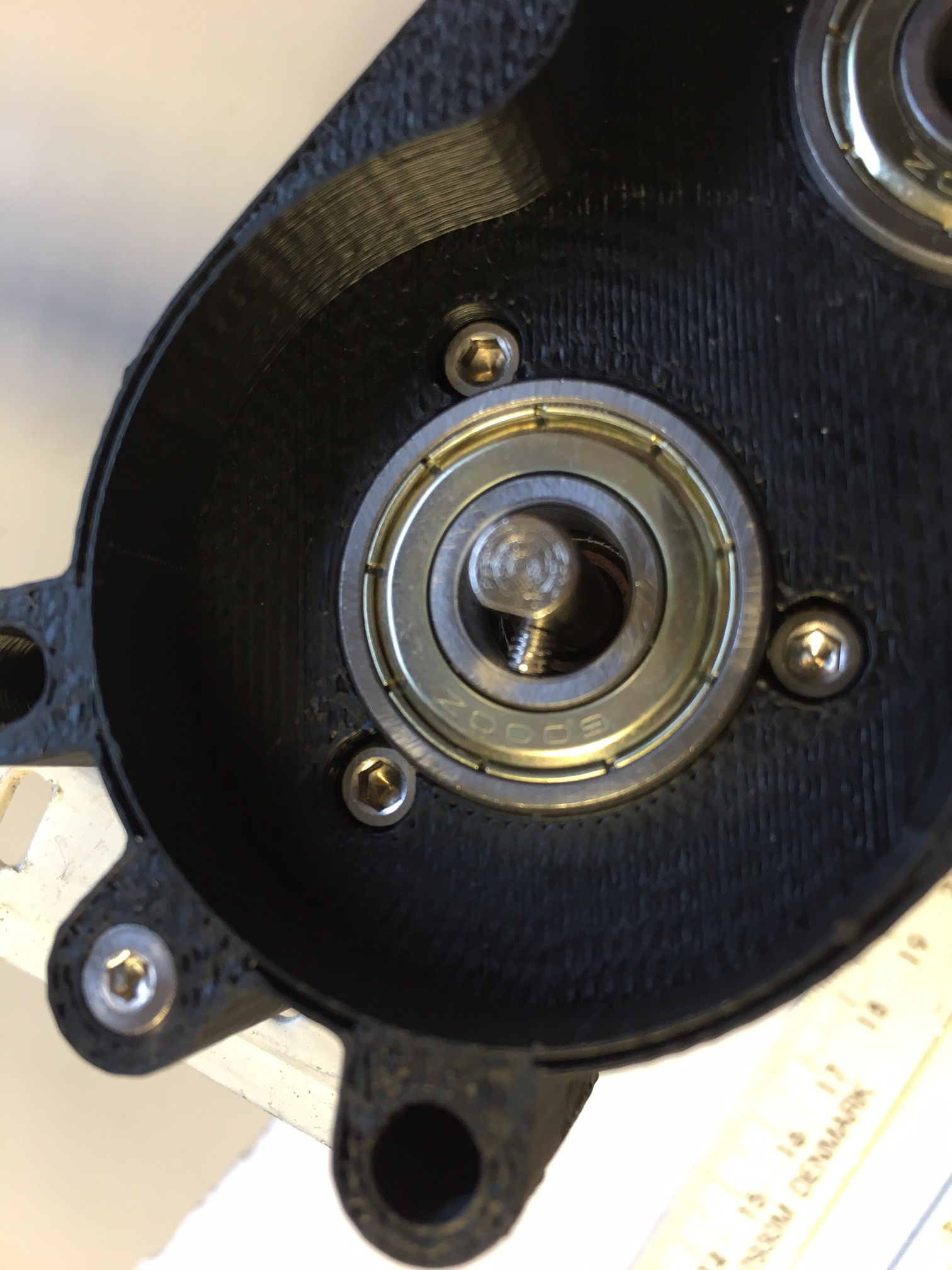

Grub screws are a standard way of gripping a D shaft from circular metal parts but 'the 3D print would never be strong enough for the thread to hold' I hear you all cry. Don't worry I haven't gone mad. I realised that because the shaft is inside the inner race of the bearing where the D shaft from the motor drives it, I can use the bearing to reinforce things.

I wedged two bits of scrap wood that happened to be the perfect length inside to keep the belt tension and slid the bearings off the rollers on the motor side. The right hand roller is the one that needed the repair (also note that I couldn't remove the grass while the motor was attached or while my wooden wedges were in place!)

I found an M3 grub screw that looked close and filed the end down (holding it clamped in mole grips) to make the length exactly fit between the flat of the D on the motor shaft and the inner race of the bearing.

I drilled a 2.6mm hole in the 3D print and screwed the grub screw flush. I then spent a couple of minutes getting the alignment perfect and slid the rollers back into their bearings.

Once reassembled I naturally went straight outside and slowly mowed 2-3 fistfulls of grass (alas I didn't have anyone to video this time but will be sure to get some footage soon).

The next issue I encountered was that the bodged frame does not stay square, which causes the belts to move sideways, in turn adding more off centre loading to make the frame distort more.

I have some aluminium extrusion from a scrap golf trolley that I plan to upgrade it with, but I will bring it as is to EMF, so anyone there who is interested, come find me!

Until next time...

jellmeister

jellmeister

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.