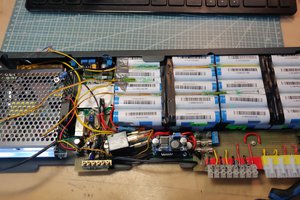

Starting with some 18650 batteries my son had given me, I decided to design a BT beacon that would use them.

A Beacon Battery System

A low cost smart battery for Bluetooth Beacons

A low cost smart battery for Bluetooth Beacons

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Starting with some 18650 batteries my son had given me, I decided to design a BT beacon that would use them.

S20180415_0004.jpgHere is a image print out prior to transfer. This is showing the 0603 resistor pads.JPEG Image - 199.84 kB - 04/15/2018 at 13:58 |

|

|

pcb001_pre-etch_cropped.jpgA board prior to etching. This is where I noticed the problem as regards to the lack of mirroring. I use toner transfer method via the cold process(i.e. mix acetone/alcohol, coat the board, apply paper, clamp, wait, remove paper under running water)JPEG Image - 670.87 kB - 04/10/2018 at 11:24 |

|

|

pcb001_cropped.jpgOne of my early attempts. Looked fine until I noticed that I had failed to mirror the image prior to printing... ArrgghhhJPEG Image - 614.58 kB - 04/10/2018 at 11:21 |

|

|

board_copper_1.14_A.pdfAn early attempt to print out a PCB. Then I noticed that Eagle had not included some pads, no vias or no contacts. That took me a little while to hunt and cure.Adobe Portable Document Format - 2.29 kB - 04/10/2018 at 11:13 |

|

|

sch01_out01_18MAR18.pdfEarly schematic of the power system.Adobe Portable Document Format - 88.36 kB - 04/10/2018 at 08:49 |

|

|

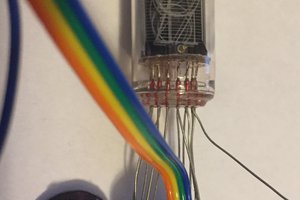

I make my at home prototypes using the cold method of toner transfer and etch with

hydrochloric acid and hydrogen peroxide.

Here are the steps I take.

1. Print a PDF mirror image of the top, pad and via layers in Eagle.

2. Go down to Kinko's/FedEx and have them print the image on their cheap glossy paper with the black and white printer on the highest/darkest settings.

3. Cut a copper clad board to fit circuit size.

4. Scrub the board with a tough pad (this is like a green scrub pad from hell) until it is shiny.

5. Wipe down board with alcohol.

6. Prepare two old PCBs, one on the edge of a table and the other will be clamped using a strong jaw clamp from Home Depot.

7. I lay the board on the edge of the table and using a combo of 3 parts acetone to 1 part alcohol (I'm using dollar store stuff here, 100% acetone and 50% alcohol) I wet the board thoroughly.

8. I then lay done a copy of my artwork face down and wait just a second.

9. I'll first press one finger down to hold in the place and using another I'll roll my finger down the board. If it's bigger than my finger, I'll use a hard rounded surface to press firmly (with out mashing it, don't want to distort if).

10. Next lay the second PCB on top, clamp tightly and come back in an hour. Most likely everything as evaporated, if not let it dry out.

11. Remove paper under running water. I like to let the water remove the paper as much as I can. Then I'll light run my finger over the board to remove the rest.

12. I then lightly scrub the board with a paper towel soaked in alcohol to remove any remaining bits of paper.

13. Next it outside to etch with a mixture of 3 parts H2O2 to 1 part HCl. Takes about 8 - 10 mins unless it's cold.

14. Clean board with acetone to remove the toner.

Using this method I think I've had one failure to transfer, and then it's just scrub it down with acetone and do it again. I easily do .016 traces with this method.

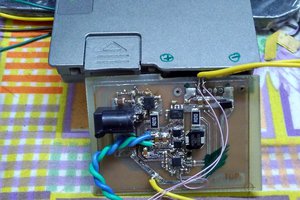

The MAX 882: This is a 3.3 V, 220 mA LDO that was designed to be run off of a battery. It uses a P-Channel FET to consume a max of 15 uA during operations, has a typical drop out voltage of 220 uV and has a variable output among other features. In this case I set the output to 210 mA, and told it to go into standby when the batteries output hits 3.14 V, no reason to kill the battery if I forgot about ti for a little while.

Unlike a lot of other regulators, it does NOT care about the ESR of it's input/output capacitors, as long as the minimum values are met. This meant that I could use electrolytic caps as long as I was careful to de-rate them for temperature. Most likely I will end up adding a ceramic or tantalum in parallel just to be one the safe side.

Yes, I know switchers are more efficient, but you've got to remember that this things entire purpose is to power a Blue Tooth module and I want a power supply that is as clean as I can get. Short of heroic efforts, a switching power supply will always generate more noise, and I'm lazy.

Next up, laying out the system.

First up was figuring out how I would recharge the battery and supply power to my BT beacon. The only part that I had were those 18650 lithium batteries my son had given me. So I sat down and started brainstorming, I decided to create the battery system first, because while all four batteries were showing about a minimum of 3.8 volts, that would not last, I needed a charger!

I've been a fan of Maxim Integrated for years, so I headed over there to do some research.

After some time (about a week) of reading app notes, data sheets, and design notes, I came up with what I thought was a simple but smart combination of a Li+ charger and a beacon power supply. During this period I also chose my BT beacon, the BL-600 made by Laird Technologies. More about it later. First the power system.

The MAX 1811 was the winner of this contest. It is a cheap (about $5.00), low parts count ( 2 capacitors) smart Li+ charger. It takes anywhere from 4.35 to 6.50 Volts in(i.e. USB standard) at either 100 mA or 500 mA.; it outputs either 4.1 V to 4.2 and does smart charging of Lithium Ion (Li+) batteries. It has enable, which I tie to the input so it is only on when we are plugged in.

There is no heat sink, instead it dissipates heat via its' ground connections at pins 3 and 6. It will cycle its charging to keep the temperature down. It can continue to work while in this thermal loop.

It comes in a SOIC-8 format and requires two caps, a 4.7 uF on the input and a minimum of 2.2 uF on the output. I'm going with 10 uF on the output because it will also be the input cap of the power regulator (This may change if I find that the reg is not happy. with the cap being on the other side of the battery)

Next, the Power Regulator!

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Enki

Enki

AIB

AIB

Kumar, Abhishek

Kumar, Abhishek

Paul Andrews

Paul Andrews