July 27, 2016 | ProgressTH We've delivered dozens of prototypes of a dermatology tool consisting of between a 3-5mm wide blade used for a variety of purposes in a local children's hospital (QSNICH in Bangkok).

The prototypes are all printed with PLA plastic, and nearly all of them at a resolution of 0.3 mm.

The prototypes are all printed with PLA plastic, and nearly all of them at a resolution of 0.3 mm.

Nurses took the prototypes and ran them through several processes in order to sterilize them before use. This includes wiping them down with 70% rubbing alcohol, soaking them in a 30% KOH solution, and a round in an ethylene oxide (EO) gas oven designed specifically for sterilizing plastic medical equipment that might not make it through an autoclave. For more information regarding how this process works, read here.

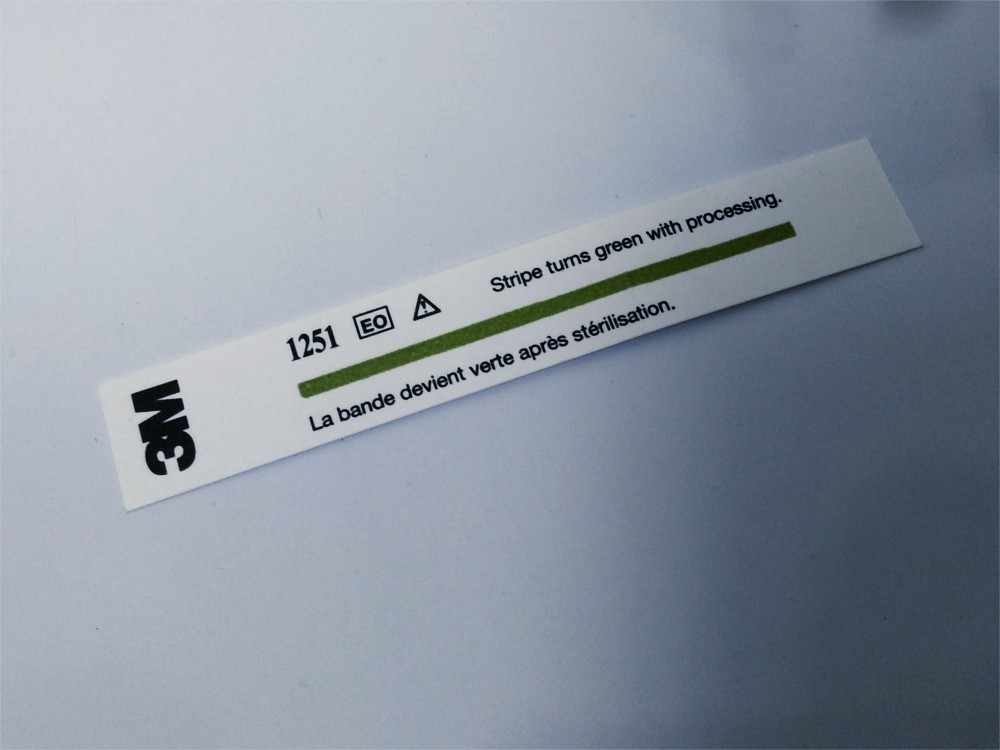

During this process, a 3M EO chemical indicator strip is used to ensure the proper conditions for the correct duration are reached within the chamber to ensure full sterilization.

For instruments printed out using a 0.3 mm resolution, it seems after repeated sterilization cycles, some of the layers near the edges start to come apart. We've tried to fix this by using a 0.15 mm resolution. The layers are much closer, denser, and so might resist coming apart as easily.

We shared our own research with the hospital regarding concerns some designers have had using 3D printing regarding food safety, specifically the microscopic structure of a 3D printed object and the possibility of bacteria hiding in relatively unseen crevices.

3D printing models is one thing, printing out medical devices is another. We're using all the tools and processes at our disposal to ensure these short-run prototypes are sterilized and safe for use in a clinical setting and learning a lot in the process.

3D printing models is one thing, printing out medical devices is another. We're using all the tools and processes at our disposal to ensure these short-run prototypes are sterilized and safe for use in a clinical setting and learning a lot in the process.

For other makers out there interested in a similar project, make sure to work together with experienced medical professionals who have the tools and knowledge to ensure the safe testing of new, custom-made instruments and equipment for their hospital.

Follow ProgressTH.org on Facebook here or on Twitter here.

ProgressTH

ProgressTH

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.