All of the capacitive methods listed on my previous log have something in common, they need a capacitive probe where the soil acts as the dielectric core.

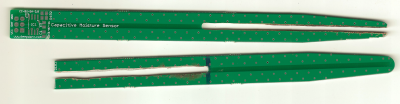

I found that coplanar electrodes is the best way to emulate a capacitor using cooper pads on a printed circuit. In the case of a double sided pcb, we need to use the same polarities on both sides of the pcb, in order to ignore the material that the pcb is made of (FR4, paper fiber, etc).

More info here: http://zerocharactersleft.blogspot.mx/2011/11/pcb-as-capacitive-soil-moisture-sensor.html

Is important that the geometry of the board allows it to be placed easily on the ground. Also, all the probe body needs to be water isolated because the material the pcb is made of can store moisture on the long run (FR4).

Doing this can result in other problems, the same material isolating water from the board, can begin to store water, causing drifting problems measuring capacitance.

More info about this, here: http://www.deepdarc.com/2011/09/08/square-one/

Valentin Ortega

Valentin Ortega

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

You have to place sensor in plastic body. This is the way to go.

Something like this

http://vegimatics.com/IMAG1335.jpg

Are you sure? yes | no

I don't think FR4 is a good base for the sensing element, it will absorb a lot of moisture. It may even wick the moisture up from the ground to the surface and cause a very chaotic moisture gradient right at the sensor element. A plastic coating will block liquid water and can protect electronics, but it is my understanding that water diffuses into and through all plastics, which means it is not helping when put on the sensor element.

Are you sure? yes | no

What do you think about an hydrophobic coating?

Are you sure? yes | no

I guess that would keep liquid water away from the solder mask, but would that help to steady the moisture gradient in the FR4 of the sensor? If the sensing element and at least the oscillator (e.g. 555 if that is what is used) are buried at the depth for which the moisture measurement is wanted that should take care of the concern I had with a moisture gradient near the sensor element. It does, unfortunately, suggest a second board above ground.

Are you sure? yes | no