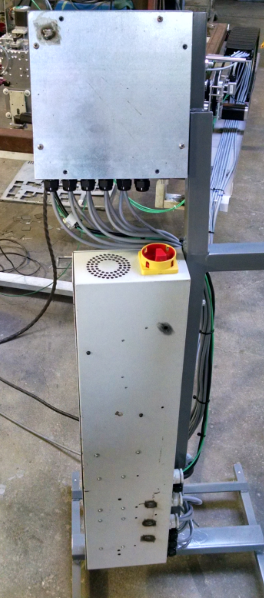

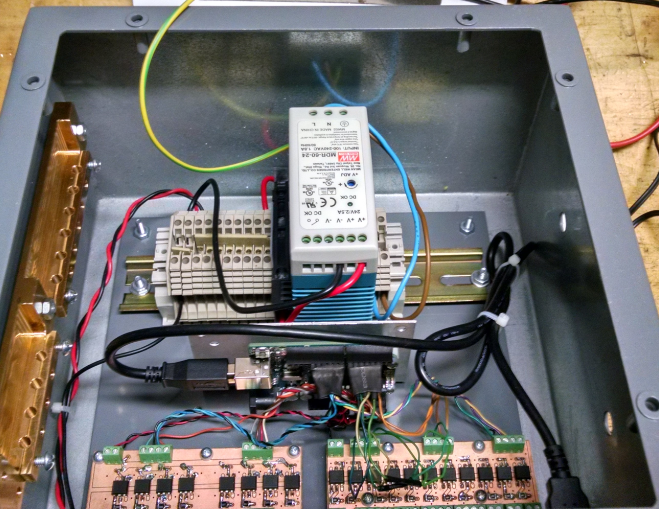

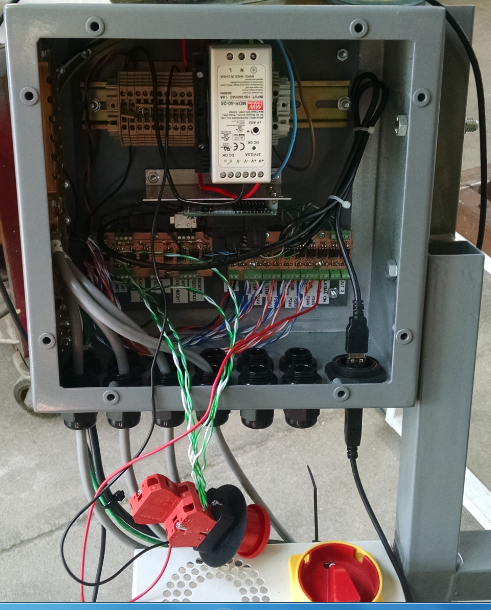

The controller box started out as a headless control with the USB to the UNO being fed out of the bottom.

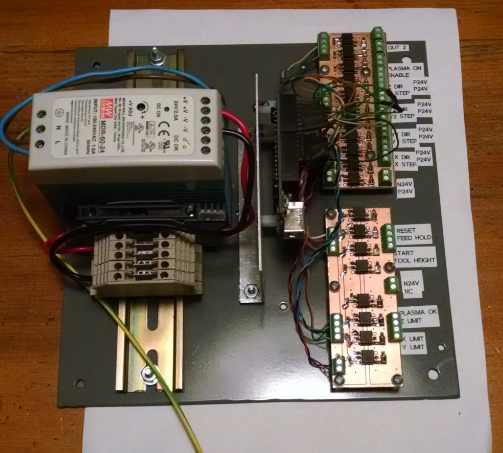

It did not have an estop, start, hold or reset button. The guts were a lot simple too. The back plane just had a 24V power supply, UNO, and a input/output opto coupled boards.

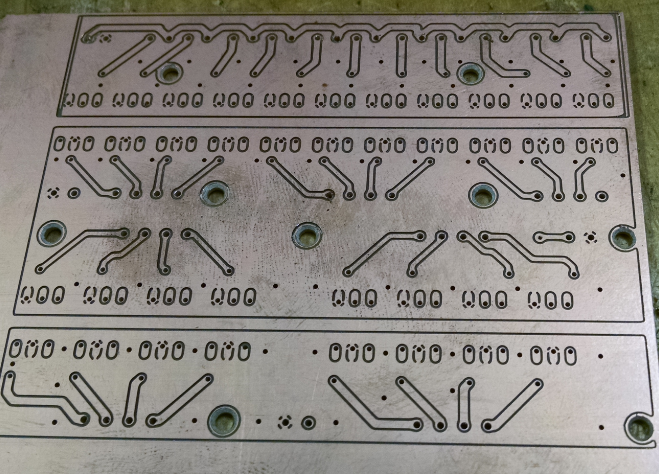

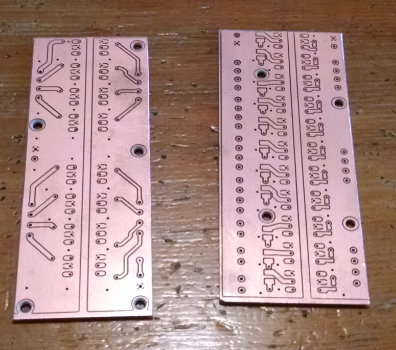

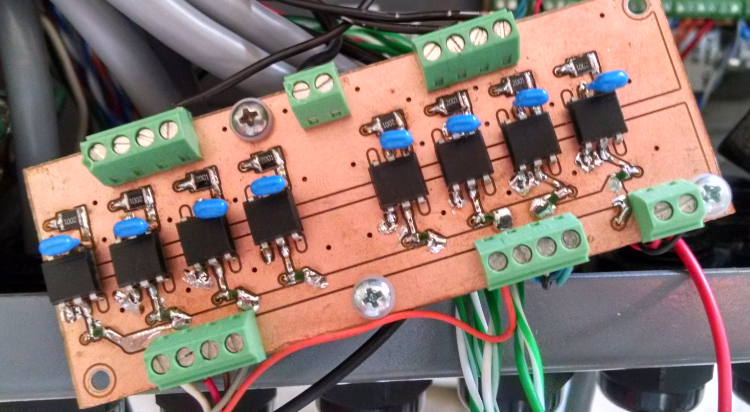

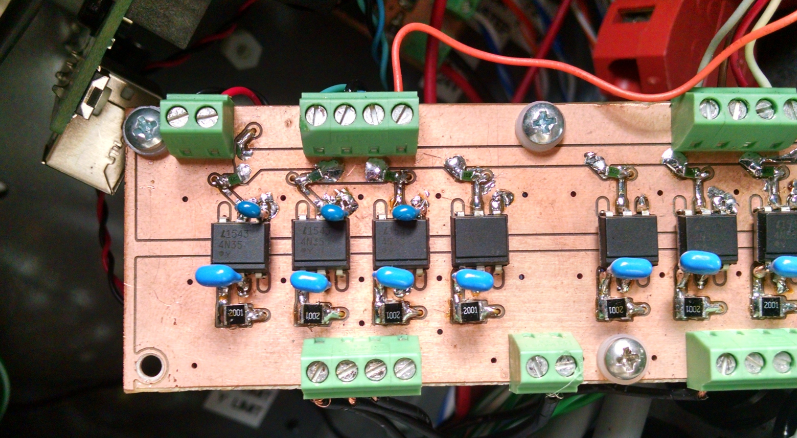

The UNO is running GRBL with few modifications to the settings. The input/output boards were designed with Eagle. Then milled out on the CNC:

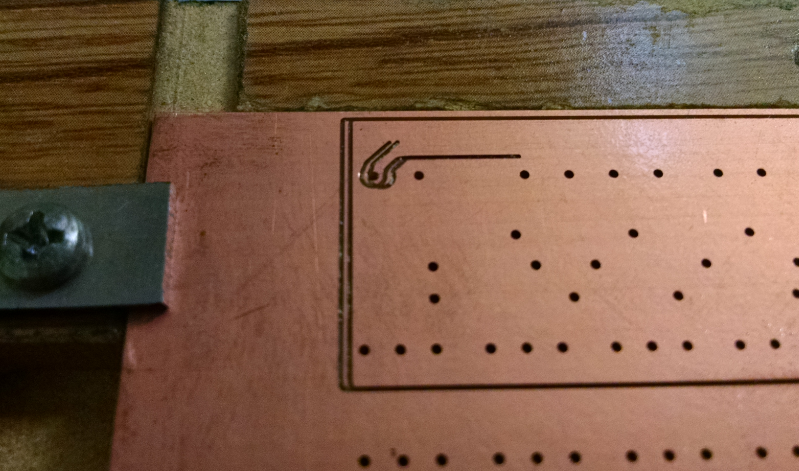

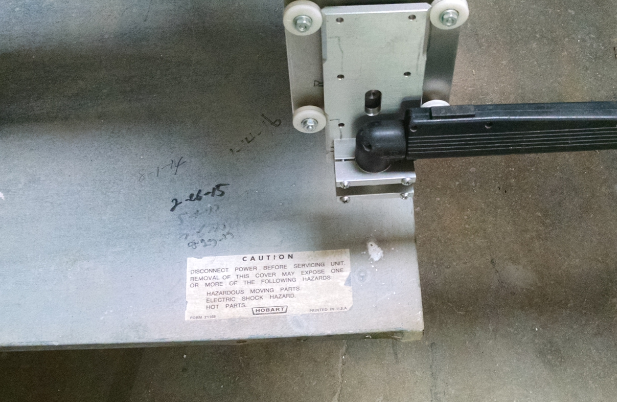

Flipping between the sides, I ran into an offset issue though and had to adjust.

Both boards were milled on a single double sided pcb:

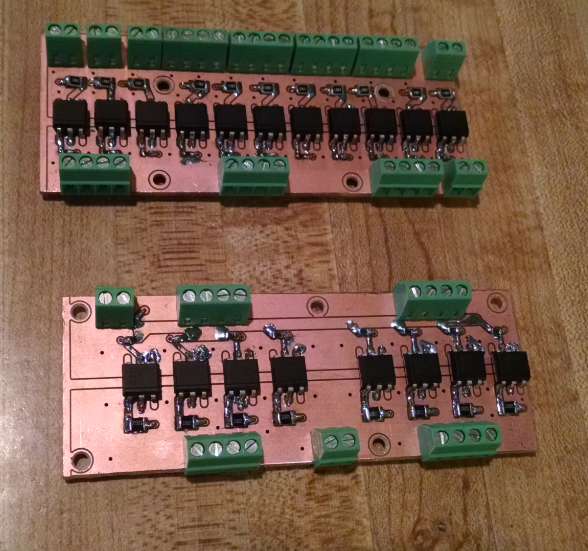

These were cut apart and ready for components to be populated.

Soldering the surface mount resistors was a task. Seeing reflow ovens soldering, makes me want to build one myself.

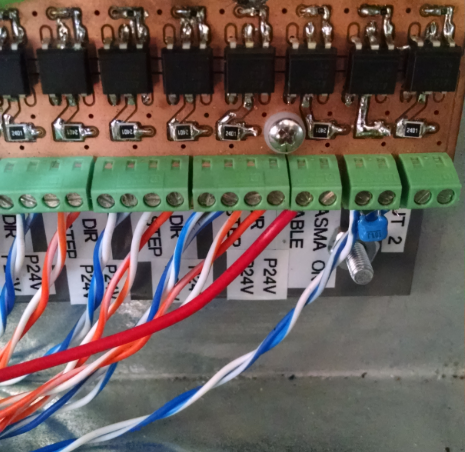

The backplane fit nicely in the enclosure:

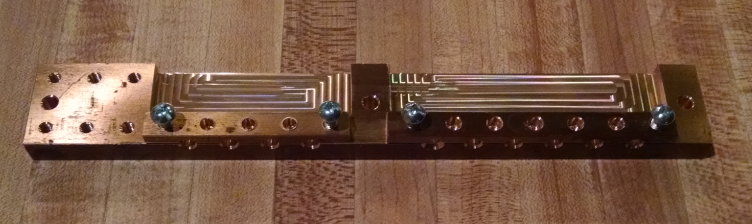

To the left is a ground bar that distributes the ground connections and also an attempt to ground out the shielded cables. Below is a complete view of the ground.

The stepper driver cables were then wired on the bottom of the pcbs.

There was a temporary estop attached while some testing was done to verify cable routing. Along the way, there was issues with poor solder joints and miswiring between the UNO and output board. When that was sorted out, testing could begin. The lower right of the controller box had a bulkhead USB passthrough that allowed a laptop be connected and power up the UNO. The laptop ran Universal GCode Sender and was painless in operation. A little effort was required in installing, but came down to reading docs to figure it out. The first few cuts by the plasma table were nerve racking, but worked fine for the most part.

And more testing was done:

Cambam was used to make the letter B, but the majority of testing was hand written code that cut out a square. The circles along the bottom was not cut by the plasma table. They were already present.

Then the realization that noise in an HF start is a challenge.

The first symptom that appeared was GRBL restarting. Randomly when the plasma torch would fire, GRBL would restart. This stopped the program being fed via File Mode of Universal GCode Sender. From what I remember (I know it has only been a few months) at that time, the table and controller/driver boxes were not connected electrically. Tieing them together helped with the GRBL restart.

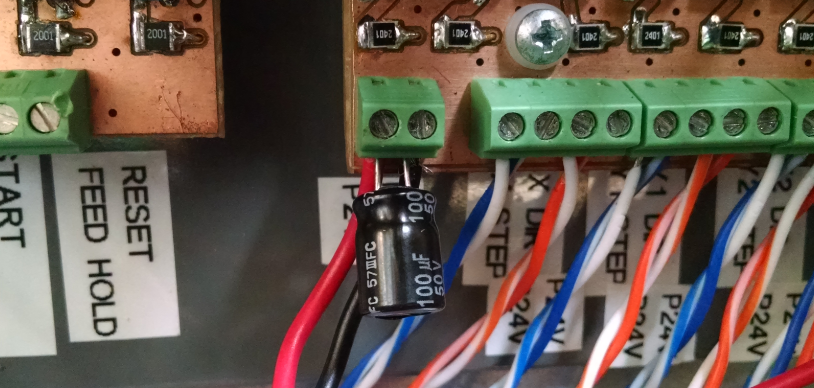

Then when the hard limits were wired in, they started to trip randomly during torch fire. Thinking it was some noise feeding in from the input and output cards, capacitors were added liberally across 24V inputs (.1 uF)

5V signal to UNO (.33 uF):

I don't have pictures for the next individual steps of capacitors, but this photo shows multiple capacitors added: 1 uF to the 5V side in parallel, the 5V power input, 100uF and .1 uF caps were installed.

Didn't seem to help out the problem. Looking into cabling to the relay, there was a loose wire. . .

All of this may have helped in minute ways, but the problem still persisted. Hard limits were randomly being triggered. In testing it was noticed that position of the laptop and cable "appeared" to help the problem. So the USB cable was stripped back to show the bare shielded cable. This was pushed against the controller box ground and it seemed to have cleared up the problem quite a bit.

This left me to believe the computer should also be contained inside of the controller box.

willbaden

willbaden

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.