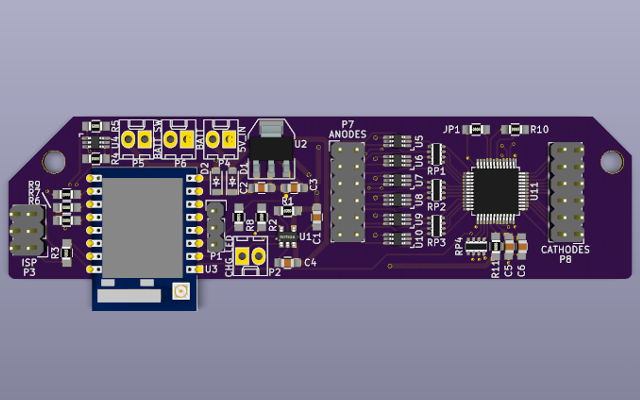

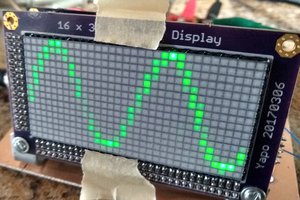

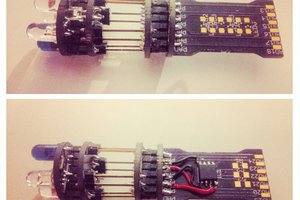

An LED traffic signal, converted to a battery-powered, LED matrix controlled by an ESP8266. The controller is derived from an Adafruit Feather HUZZAH, but generally allowing higher currents, and with no built-in USB-to-UART chip. The LED matrix is driven by an STP24DP05 constant-current LED driver. The ESP8266 runs MicroPython, allowing easy development and testing.

Traffic Signal LED Matrix Display

A networked LED matrix display made from a surplus LED traffic signal

Clara Hobbs

Clara Hobbs

Anool Mahidharia

Anool Mahidharia

Ted Yapo

Ted Yapo

OK Design

OK Design

davedarko

davedarko