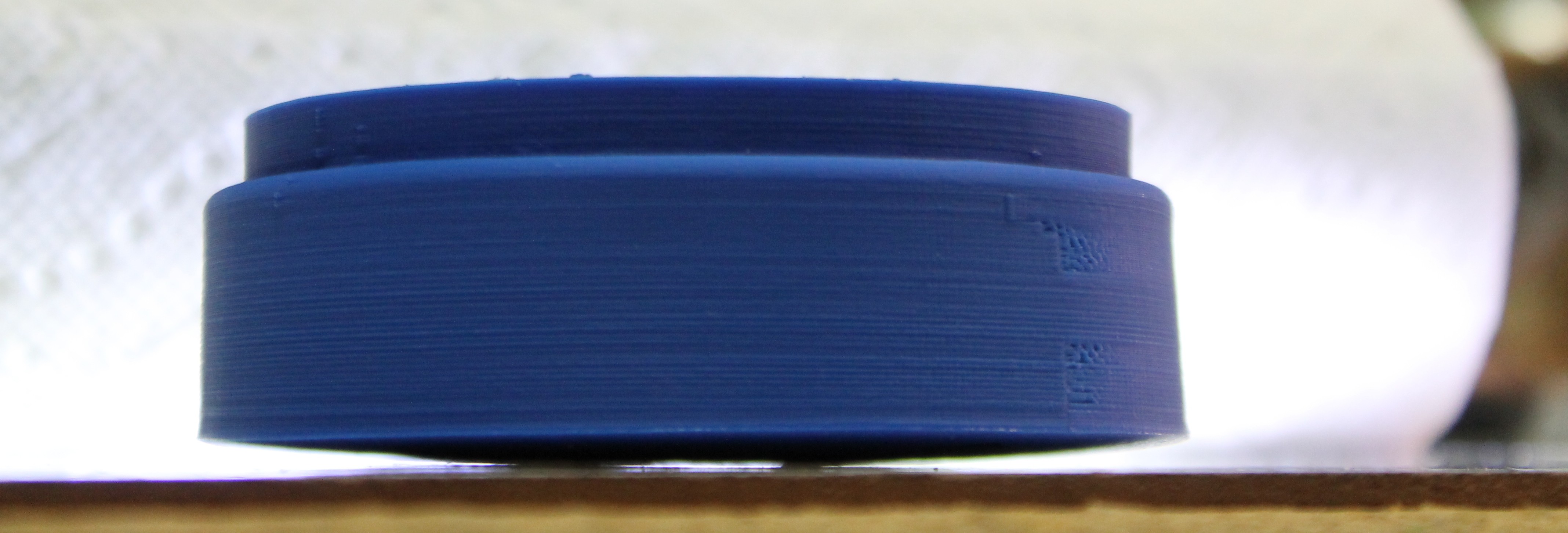

The first couple of AT buttons we printed turned out well, but we quickly noticed a trend of warped bases where the edges of the PLA button tended to lift off of the printer's build plate.

The curved bottom meant buttons would rock and make using them difficult. A solution was needed, and since I couldn't manage to tune the warping out of our printer's configuration, I turned to the button's 3D model.

My first assumption was that warping was being caused by the large surface area of the button's base layer, so I made cavities in the first few layers to decrease the surface area:

Results were disappointing. The buttons kept warping pretty much as they had prior to the modification.

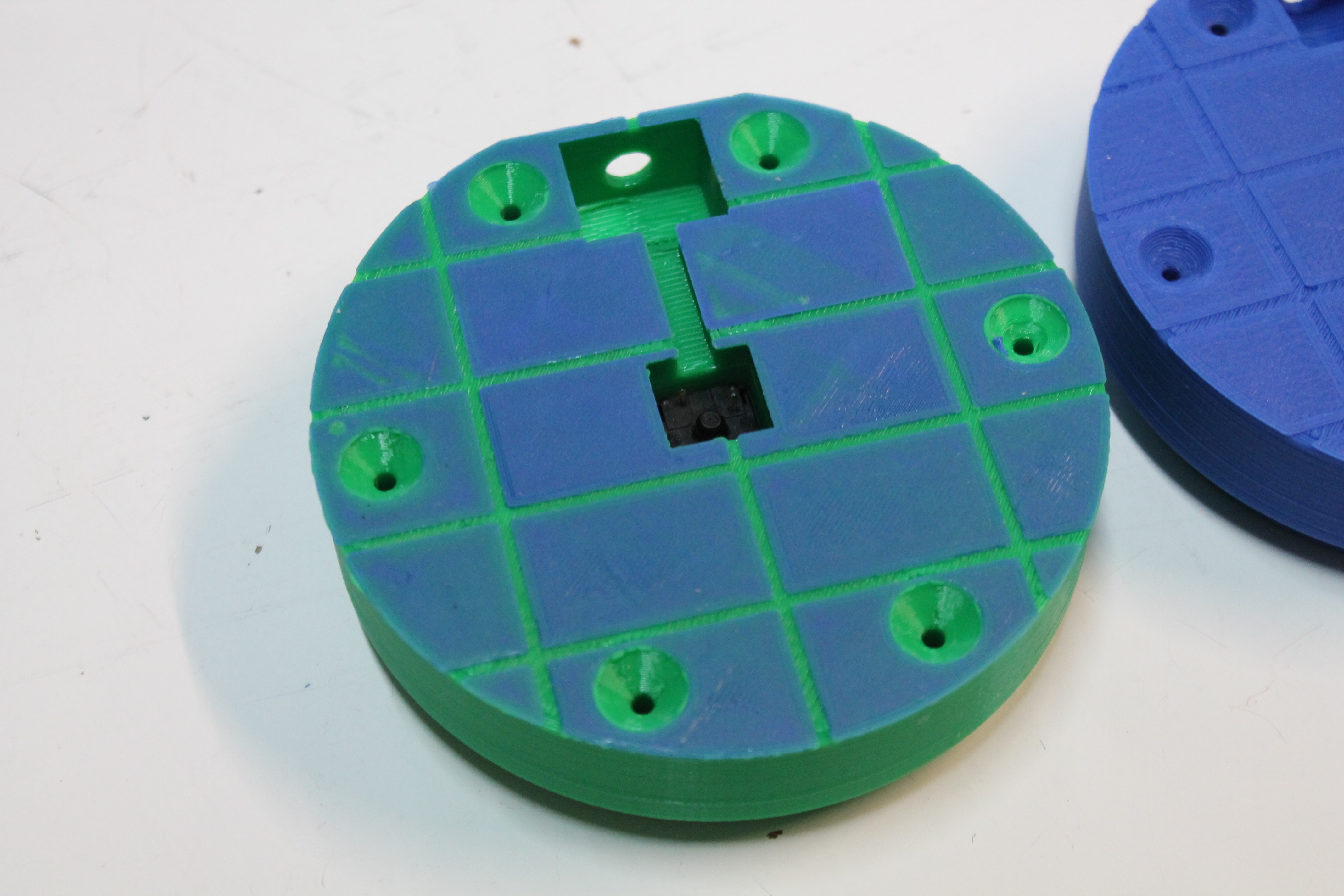

Luckily, I eventually came around to the notion that warping was a function of overall distance, not surface area. This meant we had to make the base layer contain less long segments:

Success! The buttons started printing very flat:

As you can see, the "fixed" buttons also started using a different color PLA filament. In retrospect, our small-lines solution may have been correlation instead of causation, so another pass of investigation is due at some point.

Christopher

Christopher

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.