First of all, we want to make it clear, we love this material. We really do but 3D-printing isn't easy and learning a new experimental material is an exciting and great trip and every great trip has his challenges.

Everyone that has seen something about Carbon Fiber PLA (Ours is from Proto-Pasta, best provider of all) knows that the main problem will be the nozzle and we knew it but we ordered a steel nozzle from China so in the mean time..... lets destroy the current brass nozzle.

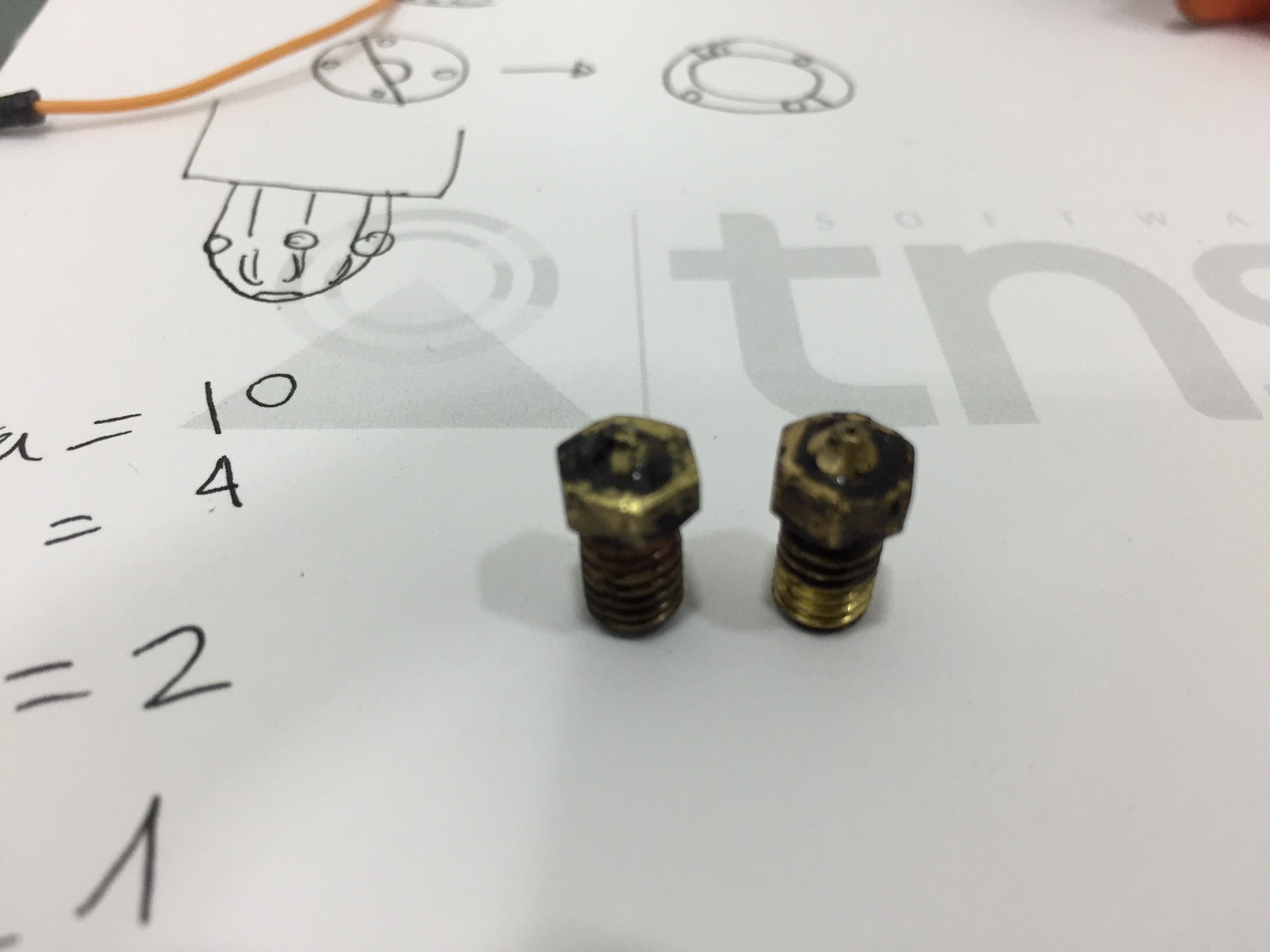

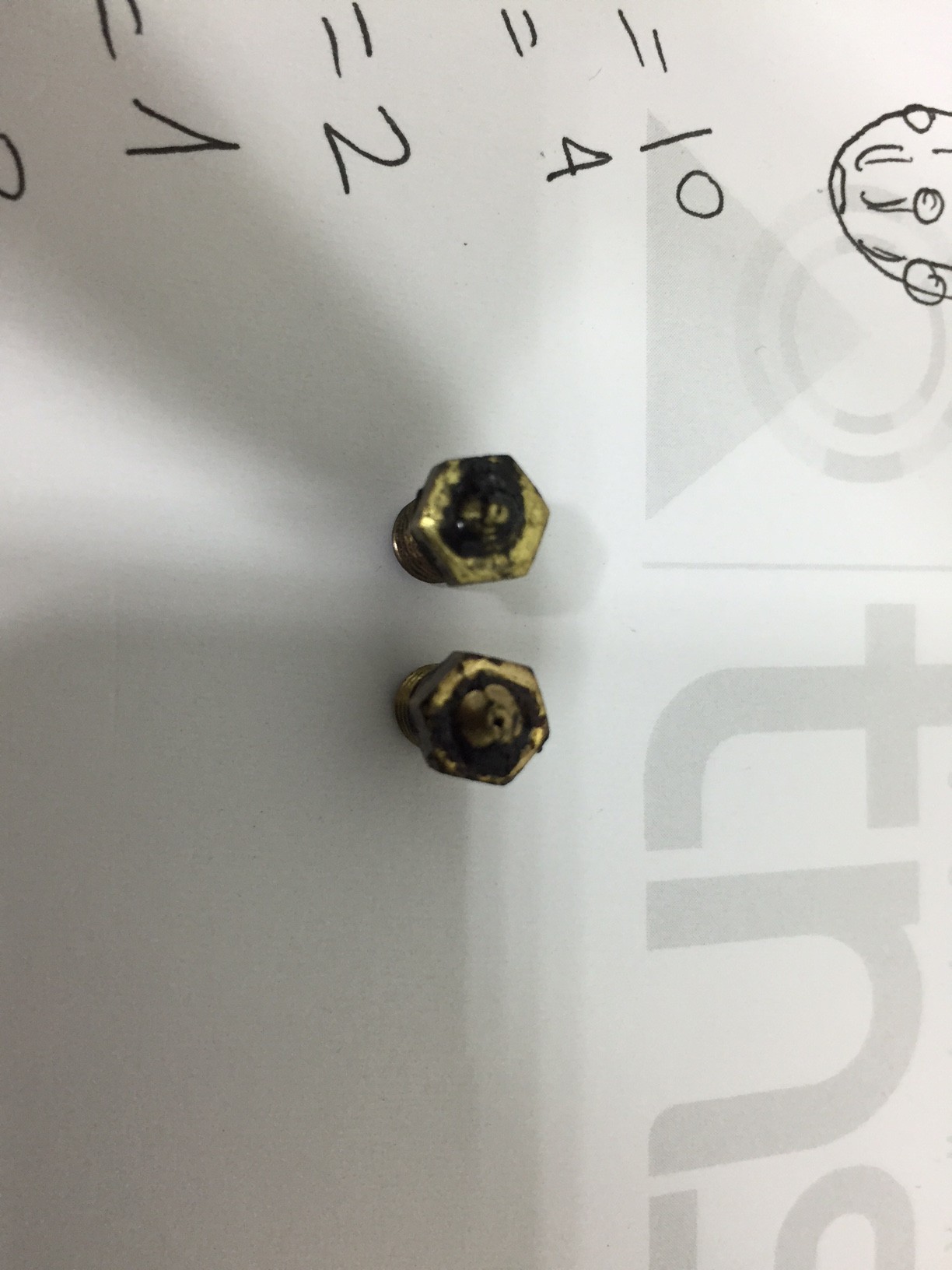

This is the end result of two brass nozzles after half a kilo with Carbon Fiber PLA.

They had a rough time, and you know that the tip of your nozzle is stretched because you'll start to have prints like this.

They had a rough time, and you know that the tip of your nozzle is stretched because you'll start to have prints like this.

But..... there is one better (https://www.proto-pasta.com/products/high-temp-carbon-fiber-pla-composite)and we are really looking forward to that one. The new Carbon Fiber PLA that can be baked, we tried to do it with the one we have and ended up with Carbon Fiber cookies. But really strong cookies!!

So when the new one arrives, we will tell you about it.

Giovanni Leal

Giovanni Leal

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.