A lot....

So since the last post we haven't stop working.

We got interviewed with the local newspaper and so on. http://www.laopinion.com.co/tecnologia/jovenes-cucutenos-crearon-una-mano-robotica-122052

Also, we changed it all up. So no more linear actuators. Yeah we know. For now on we are working with an endless screw moving a gear connected to each finger. Why did we change one of our premises do you ask? well the length of the linear actuator was a big problem for us and the travel or angle of the finger was limited by the length of the actuator.

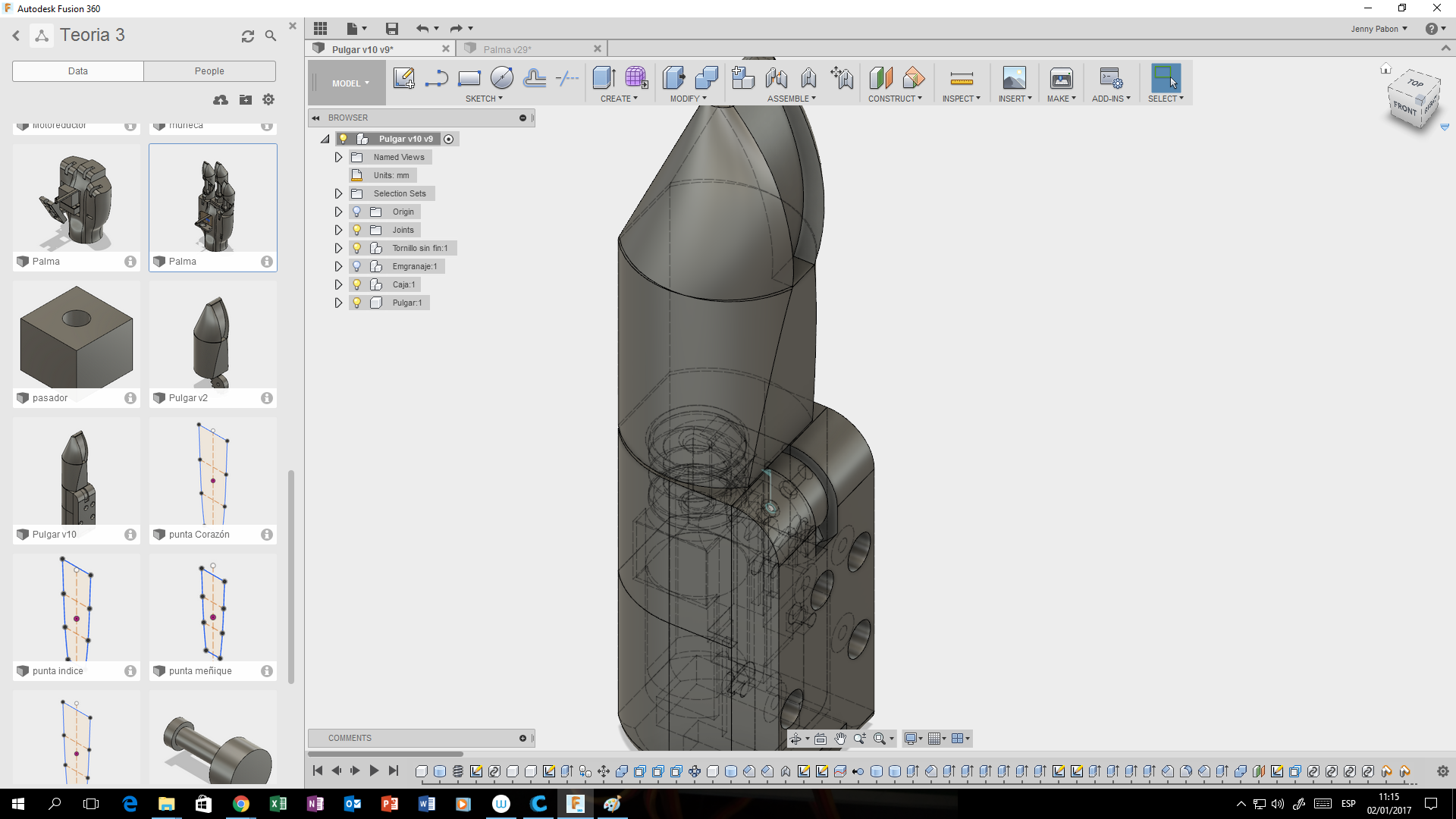

We changed the software that we used! We used AutoCAD and it was not optimal and expensive. So we opted for Fusion 360 and wao.... what a change. First of all it's just quicker, nicer and easier to use. Normally for a mechanical design we had to print something 5 to 8 times to get it right, now... simulate on the software, modify it, print it and in one go we have it perfect. Highly recommend it.

We are running test with someone. His name is Dario and he happens to have an upper limb amputation. He has been nice enough to try out our hand and so far so good! Now he is the principal motivation to finish it soon. Also he has given us some feed back. like now the fingers have rubber strips integrated to them because the grip wasn't enough for him.

But most important of all, we know you are out there. So tell us what you want to see, what sparked your curiosity to follow this project. If you want us to make a new video or post.... about what it would be?

Happy holidays everyone!

Giovanni Leal

Giovanni Leal

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

well, it has pros and cons.... His way smaller and the potenciometer is independent on the actuator so is more precise. That was the big problem and the reason why we redesign everything. The trick for this one to work is to have a tight fit, like really tight.... the screws of the palm have to be sealed really good. We will make a video showing the mechanism just for you tomorrow, stay tuned!

Are you sure? yes | no

This is simply extraordinary, I am using FreeCad 0.16 right now, and its not too bad but I am looking for a program that can print my parts in the range of at least 0.025mm of tolerance. Presently my parts are printed with 0.5mm tolerance, still not bad but the sim feature on Fusion sounds very interesting!

Happy New Year!

Are you sure? yes | no

Hello David. I don't know if it works for you but we definitely recommend it. Why we can't asure to you? because we noted that it varies between filaments but it's right there on the 0,2 %. Also.... we can actuate the joints on the program, that's like the best thing for us.

Great to ear from you!

Are you sure? yes | no

Hey Giovanni, I like the screw type design you switched to. I bet it gives smoother operation, maybe a more "realistic" movement for those wearing the prosthetic.

Are you sure? yes | no