Powder tried:

| Powder | Result |

| Plaster + Talcum powder | Not enough strength both immediately after print and after setting |

| Plaster + sugar + dextrin | Increase wet strength, but very difficult to spread. Also very messy. |

| Salt + dextrin | Good wet strength, improved with baking. Easy to spread. |

The final powder is made by baking table salt to dry. Then ground to fine powder with coffee grinder. The powder is mixed at 8:1 with Malt dextrin.

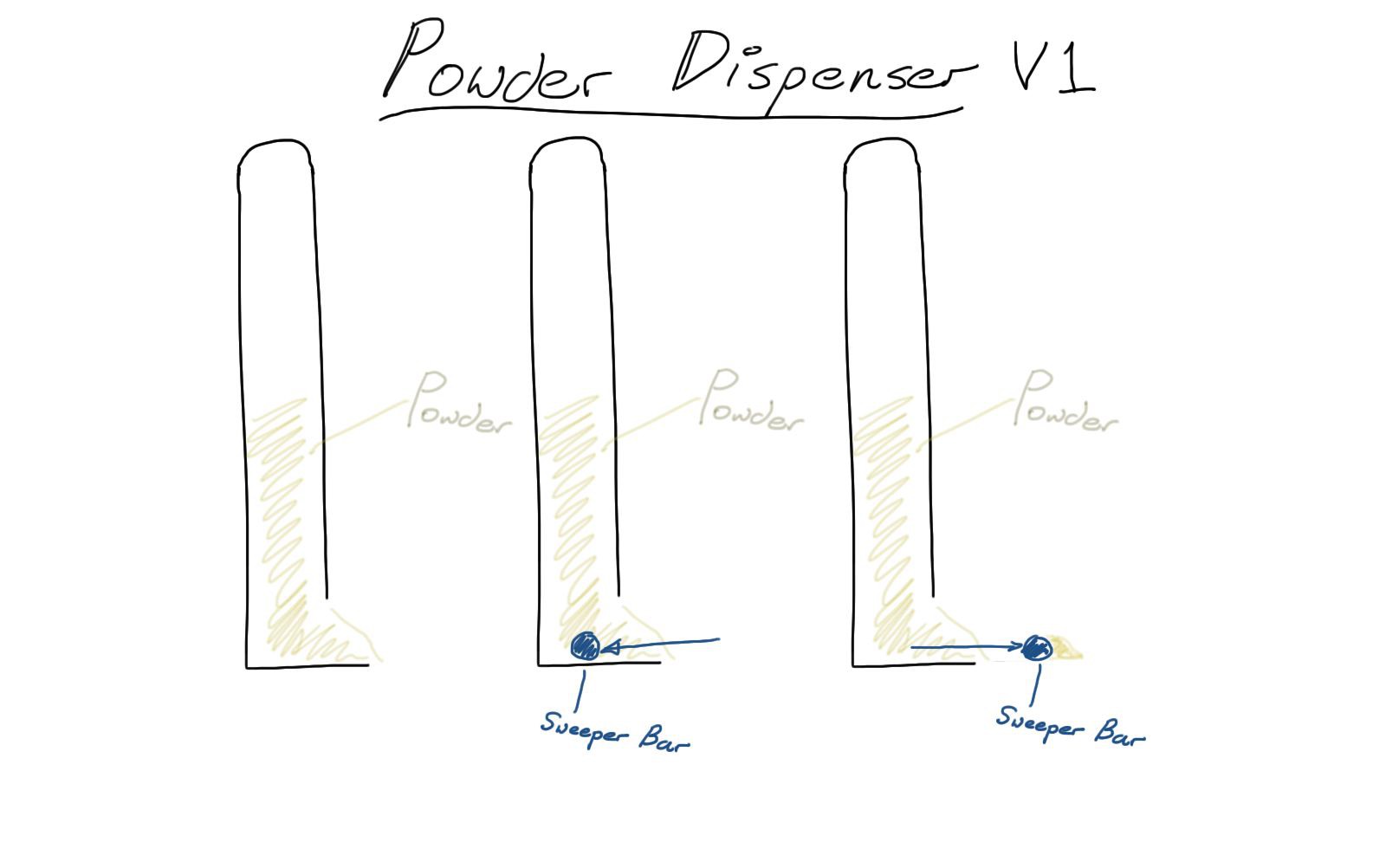

For the dispenser the first simple design was a simple sheet metal bent into a box. Below is a picture to explain it.

It is a completely passive system as the sweeper bar is moving. The further back the bar moves, the more powder it will pickup.

This dispenser place strain on the sweeper bar and hence does not fit into current design.

JLAM

JLAM

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.