The two digit displays a few things.

1) Alternate battery voltage Integer & decimal for precise voltage

calibration to compensate for cabling & connection losses . eg 12.74

2) Single integer & decimal for current load setting up to 9.9A.

3) Cumulative Ah while running.

4) Undervolt 'Lo', to avoid testing an undercharged battery.

5) Hi Ah >99 - 'Hi'

6) 'UP' when ready to uplink the discharge log to PC

The Design files link contains build instructions, How it works, , BOM, HEX code and parts sourcing from Jameco.

mosaicmerc

mosaicmerc

Sagar 001

Sagar 001

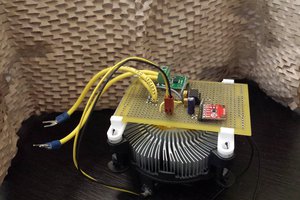

A board redesign is underway as some lamp loads get quite hot and cause the FET driver to fail due to its' proximity to the lamps and load resistors. The updated layout will bump the FET to a heavier duty unit and provide space for a small heat sink and a radiant heat shield for the FET and the FET driver.