This project requires reaction vessels that can handle high temperatures, and are corrosion resistant. My original idea was to use 5-gallon stainless steel "Cornelius" style kegs as the reaction vessels to produce syngas, because kegs are readily available, and stainless steel can handle the temps I'll be working with. But I soon found out that the rubberized handles on Corny kegs are very difficult to remove- you basically have to burn them off, which is, uh, kind of the opposite of what I want to do (I would like the toxic smoke to stay INSIDE the machine, thank you very much). So I put out a call to facebook for REAL kegs, and my friends came through! I now have these 3 slimline style Sanke kegs to experiment with!

When I got home, I started trying to figure out how to make a secure and gastight, but also quickly removable connection to the top of these kegs to collect the gas, and once I realized the taps I thought I could use weren't going to be secure enough, was afraid I would have to custom machine something, which is not only tedious and expensive, but also makes the project that much more difficult for other people to replicate.

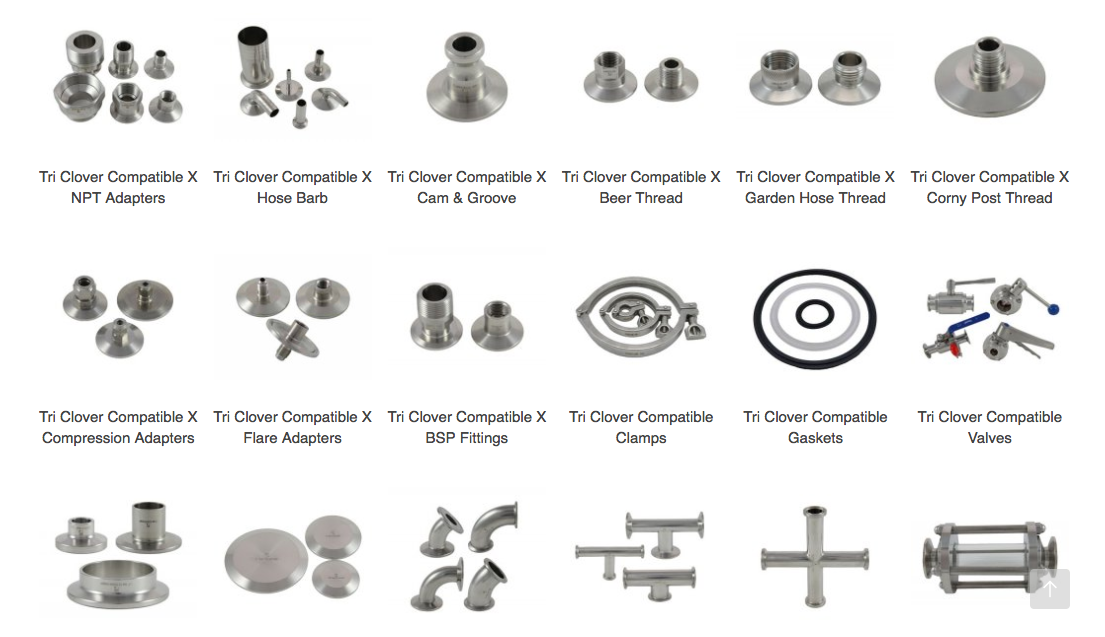

(this screenshot is from Brewershardware.com)

So I jumped on google, and was very pleased to discover that there is a HUGE range of every possible stainless steel fitting and connector I could possible hope for, readily available for not that much money, because of the home-brew industry. You can get stainless steel fittings in every shape and thread, butterfly valves, sight glasses, check valves, manifolds, and basically any other connection you can imagine, all with inter-compatible 2" tri-clamp connectors. Unnnnnng I'm in maker heaven. It's like a lego set for building complex, modular, high-temperature and corrosion-resistant machinery.

I ended up ordering a clamp system and this 1" NPT pipe thread fitting. This should let me securely and quickly attach my Corrugated Stainless Steel condensers to the kegs, without worrying about gas leakage or fabricating my own janky connectors. Once these parts arrive, I can start experimenting with making fuel! I'm going to start with wood pellets, because of their high energy content, flowable shape, and low toxicity. Stay tuned!

Sam Smith

Sam Smith

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.