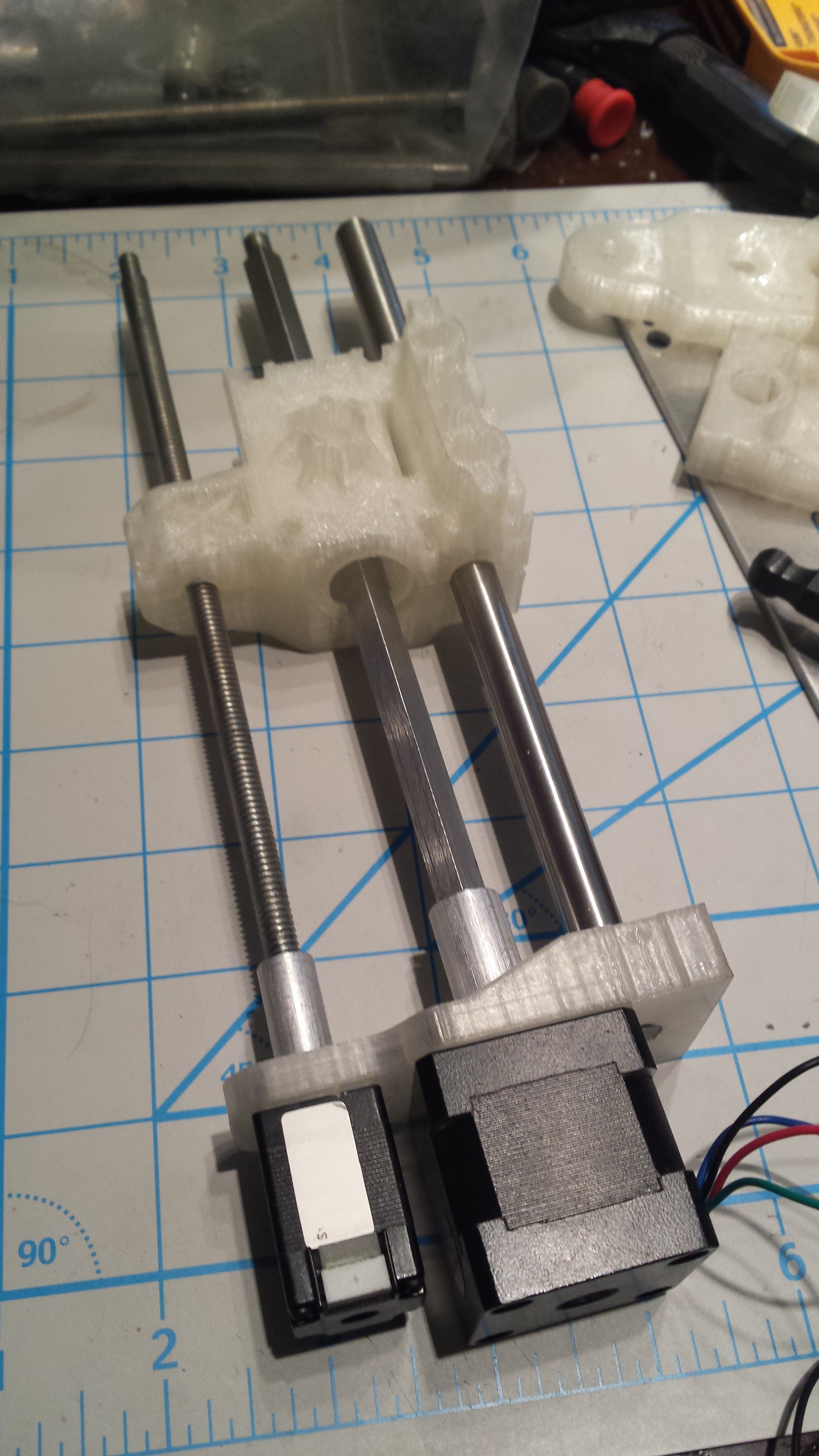

So I worked on assembling one full side of the Z-axis today and ran into a few issues. The first is that our NEMA 14 steppers that were purchased from Pololu have a slightly longer shaft than the original batch from an alternative supplier. I should have measured them prior to any machining but didn't think to do so. The model has been updated to reflect the new shaft length, the only major change is that the X-axis square drive has a slightly shorter engagement with the coupler. Once the parts are modified I can install the last bearing and begin assembling the clamshell prototype.

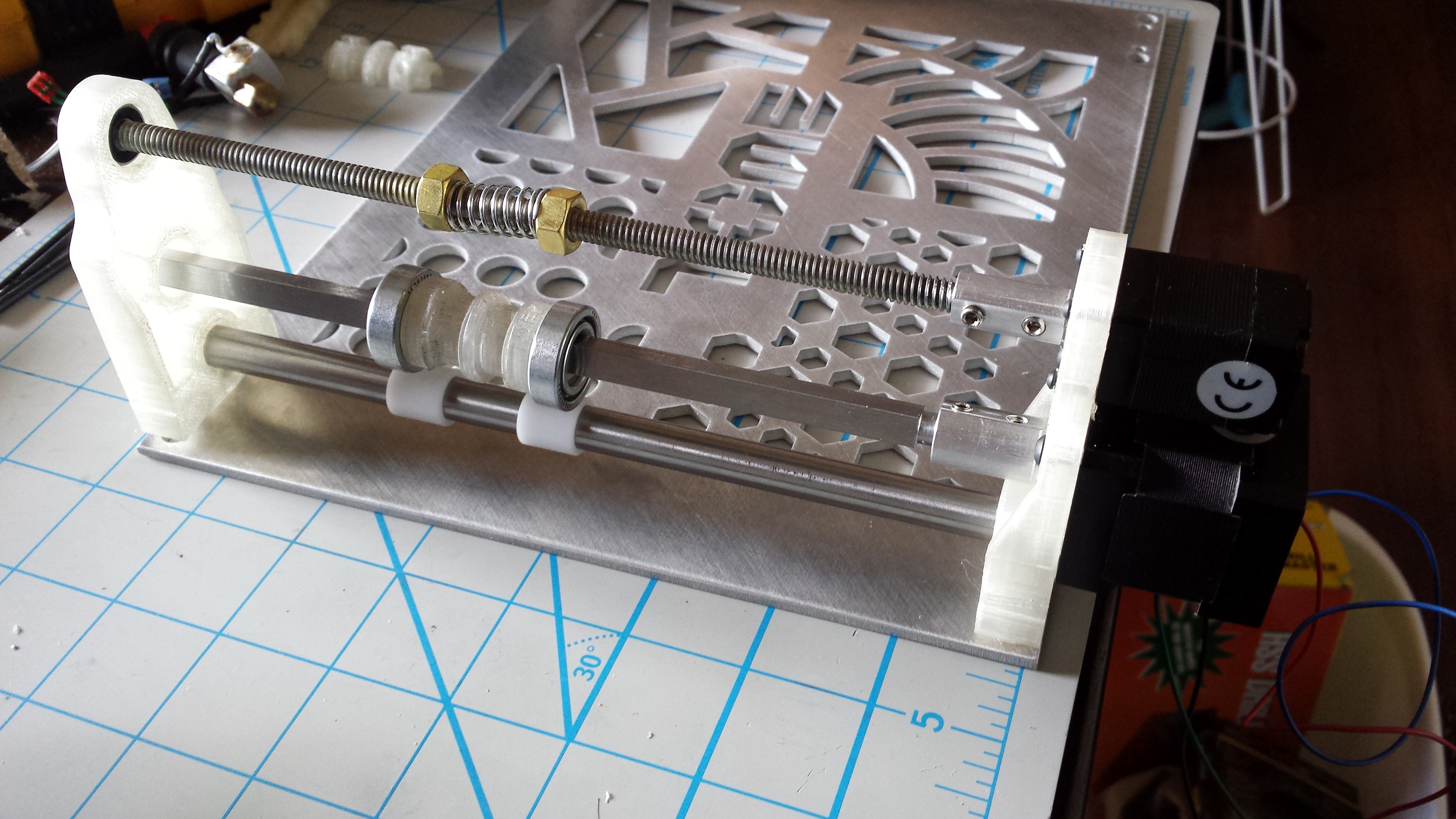

Here is the full assembly with the backpane, the top bearing mount appears to be floating in this image because I had not yet opened up the dowel pin locating holes to the right dimension.

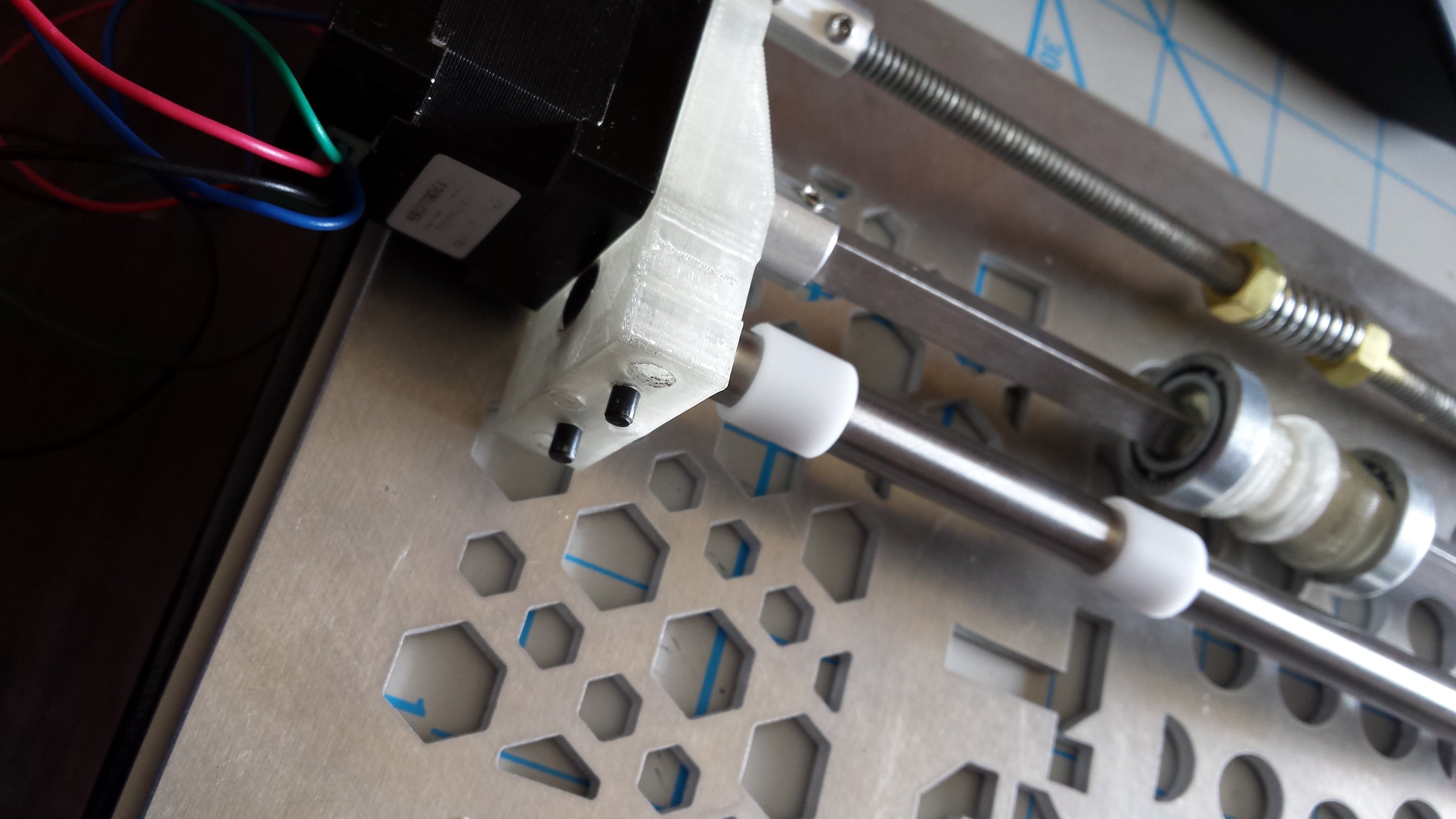

And here you can see the dowel pins inserted. This backplate is the original one I cut which is why it does not have holes to provide access to the guide rod clamping set screws from the back. I hate wasting material so I'll be adding these tomorrow on the drill press, the model has already been adjusted.

I plan on uploading the following parts to GrabCAD this week since they have been prototyped and are unlikely to change:

1. Z-Axis Guide rods

2. Lower Motor Mount

3. Upper Bearing Mount

4. NEMA 14 Coupler

5. NEMA 8 Coupler

6. Spectraline Pully

The Z-axis clamshell still needs to be modified and prototyped before it will be ready for release.

Philip Ian Haasnoot

Philip Ian Haasnoot

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.