New project, using screw drive: https://hackaday.io/project/162716-birtha-screw-drive-antenna-mast

I need an antenna mast for the RV for when we are in fringe areas to raise up and point my Yagi back towards civilization, lest I succumb the 'no internet' shakes. The RV has air suspension and brakes, so I already have a built in air source to play with.

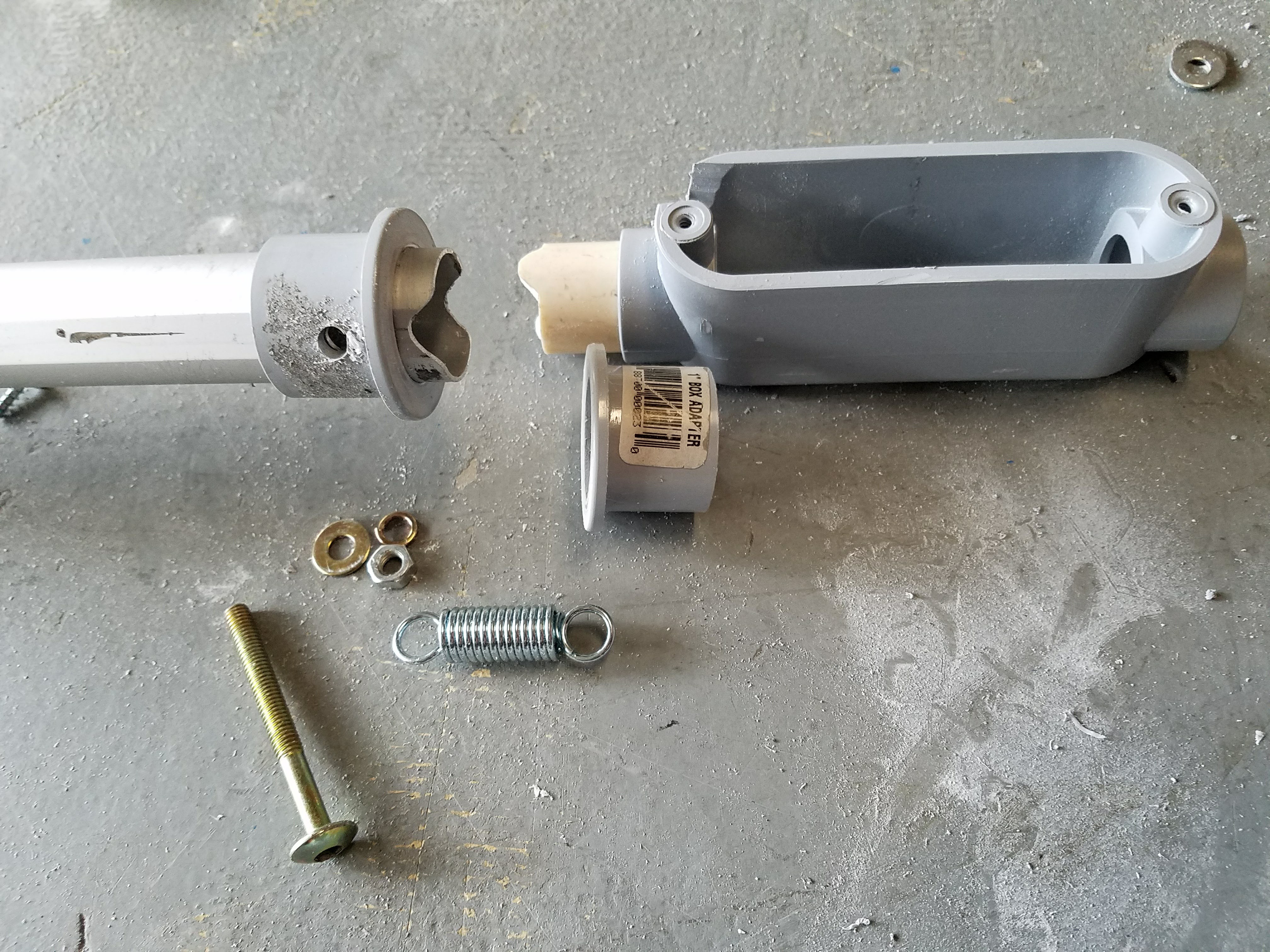

Using straight pneumatics to raise and lower a mast usually involves adding locking pins, as eventually the seals in the mast leak so it will settle back down when you remove the air source without them.

The crux of the idea is to replace the need for the telescoping sections to contain the air pressure themselves by using a cheap, expandable garden hose inside them.

The expandable garden hoses contain a silicone or latex tube under tension. As you inflate the tube (usually with water), the outer cover constrains it and forces it to expand lengthwise. They expand to approximately 3x their original length, and a 20mm (3/4in) hose will generate about 28kg (60lbs) of linear force at 80psi while doing so. When the pressure is removed, they contract back to their original size which will also provide some spring tension to retract the mast.

Previous ad-hoc experimentation with the original version of these hoses with the crinkle cover failed to retract properly when I tried this before, so this idea was scrapped before it got going.

But... I noticed that there was a new expandable style garden hose out which does away with the old crinkle cover and replaces it with an accordian style mesh.

I picked one up at Home Depot and indeed... the mesh cover slides a whole lot better on the inside of the telescoping tube. So this project was tried again... and it works.

Moving on...

The end goal here is a retractable directional antenna which aims itself.

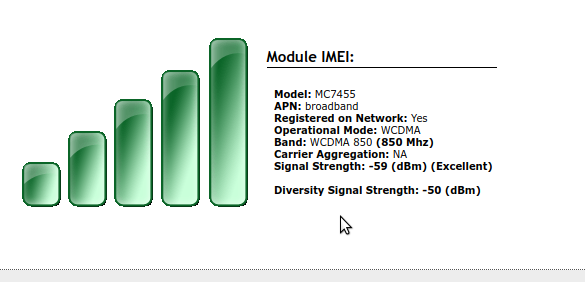

The plan to make this happen is to use the OpenSignal API, a 4rpm motor with encoder, the GPS position and compass derived orientation of the RV, and the currently connected cellular tower from the omni directional antenna.

Scan for the currently connected tower, look it up via the OpenSignal API, determine it's direction relative to the current position and orientation of the RV, switch over to the Yagi, and automatically point the antenna at it.

Daren Schwenke

Daren Schwenke

WJCarpenter

WJCarpenter

Nixie

Nixie

ric866

ric866

rbalsan1

rbalsan1