Due to requiring AC power to operate devices such as heaters and lights, I am dropping my original plan to make this project solar-powered. The new plan is to have a device which will always be on, sending periodic updates to a web server so that the greenhouse conditions can be logged and viewed online. The code will support up to 16 devices controlled by a bank of relays and allow setting unique conditions to trigger each device.

ESP32 Greenhouse Monitor

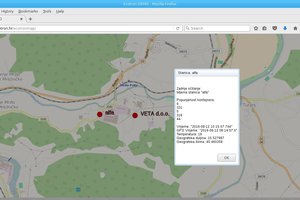

Collect temp/humidity, soil moisture, sunlight data to be stored on local web server

Jeff Taylor

Jeff Taylor

mikrotron

mikrotron

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠