Intro

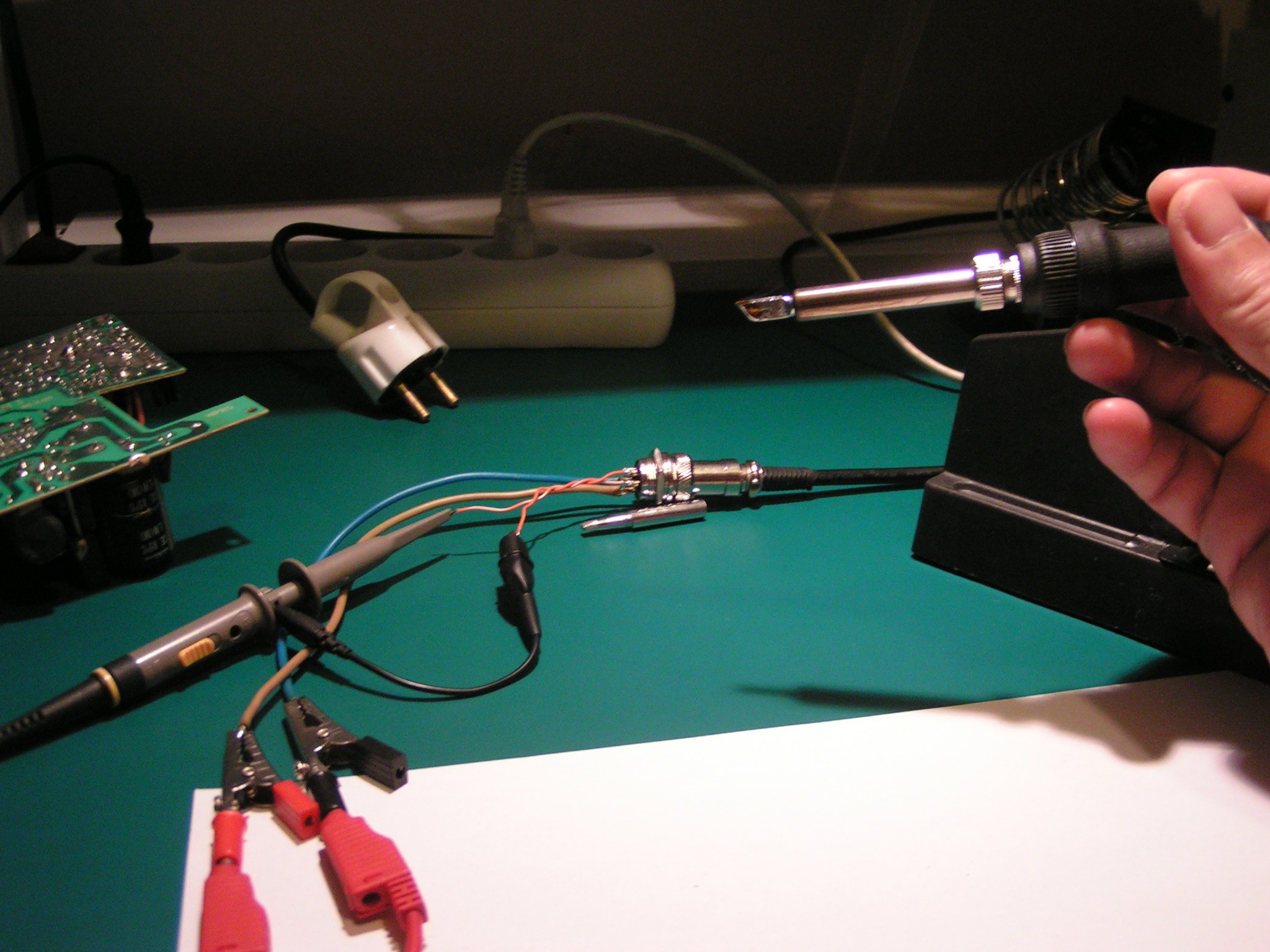

There are some very cheap soldering iron handles available as spare parts. They usually work with 900M type tips, the heating element has 50W at 24V, and the temperature sensor is a 40uV/*C type K thermocouple integrated into the heating element. Mine were Gordak type handles.

These cheap soldering irons use Hakko 900M series type of tips, but despite their similar heating element and similar soldering tips, the temperature sensor is different between the Hakko and the clones. Hakko uses a RTD, while the rest of the other producers are using a K type thermocouple.

The total cost for a non-Hakko complete handle with one tip included and free shipping is about 3-4 USD, and a pack of 10 soldering tips is about 2-3 USD with free shipping.

Setup

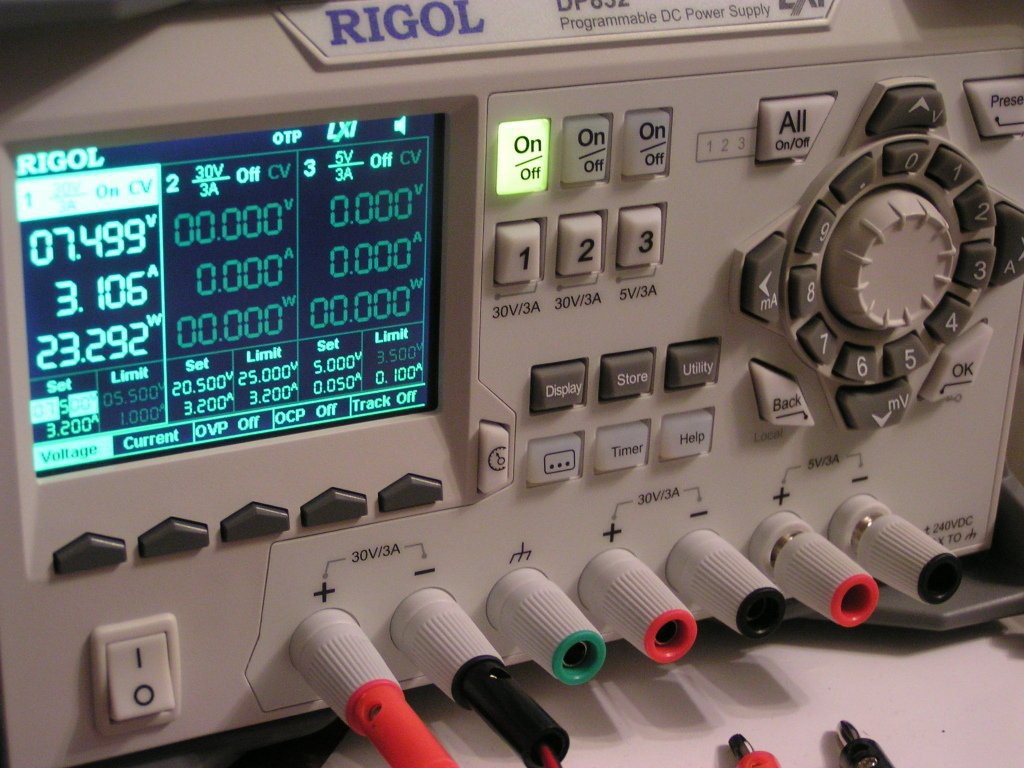

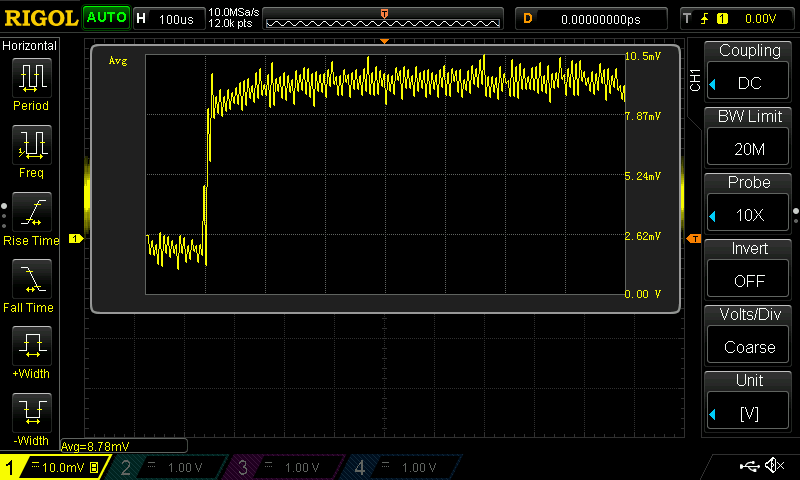

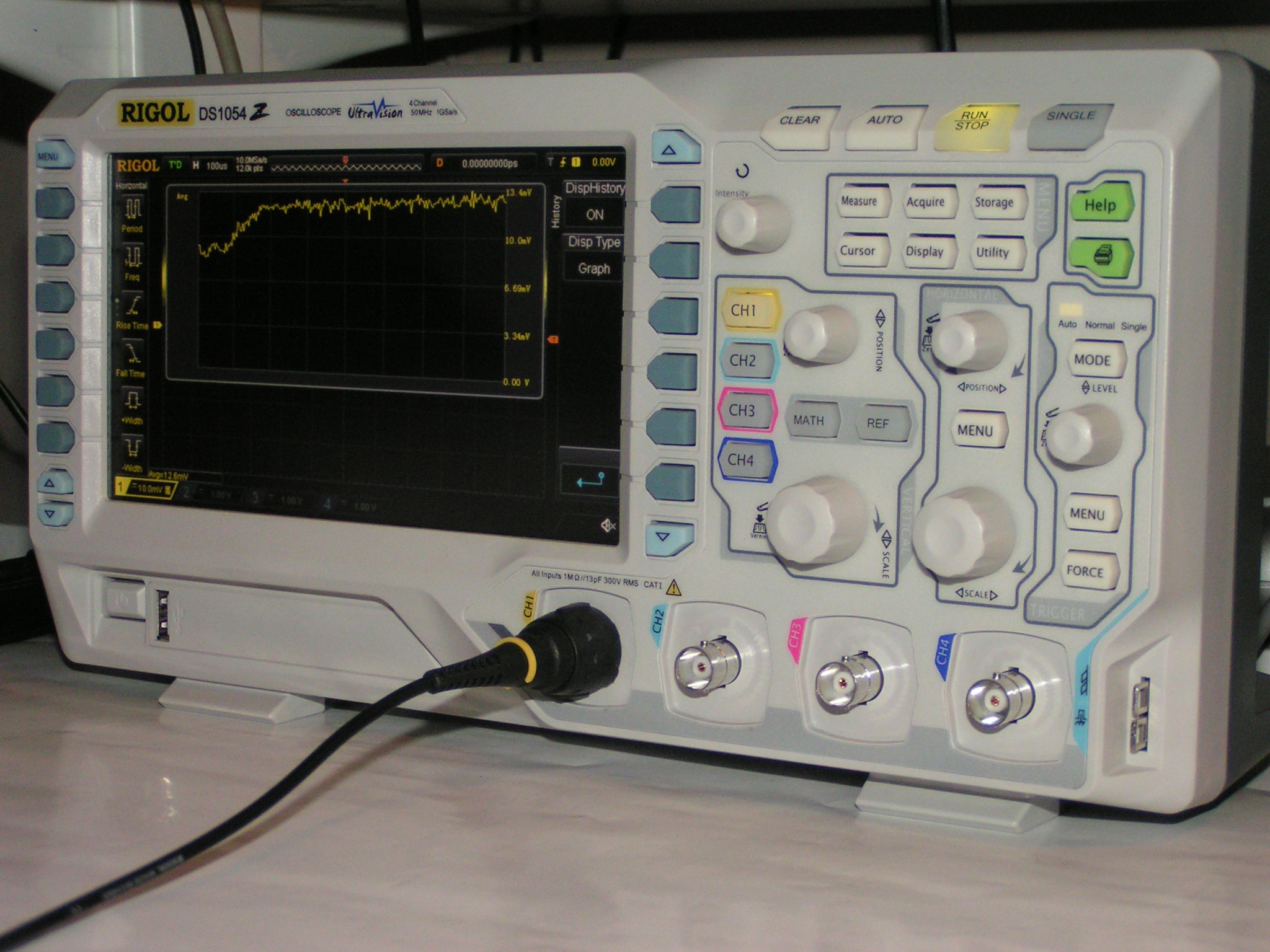

To test these soldering irons, an adjustable power source (Rigol DP832) and an oscilloscope (Rigol DS1054Z) were used. Both the source and the scope have LXI, meaning they are remote controllable from a PC via SCPI commands sent over LAN (for acronyms please see the end section, 'Acronyms').

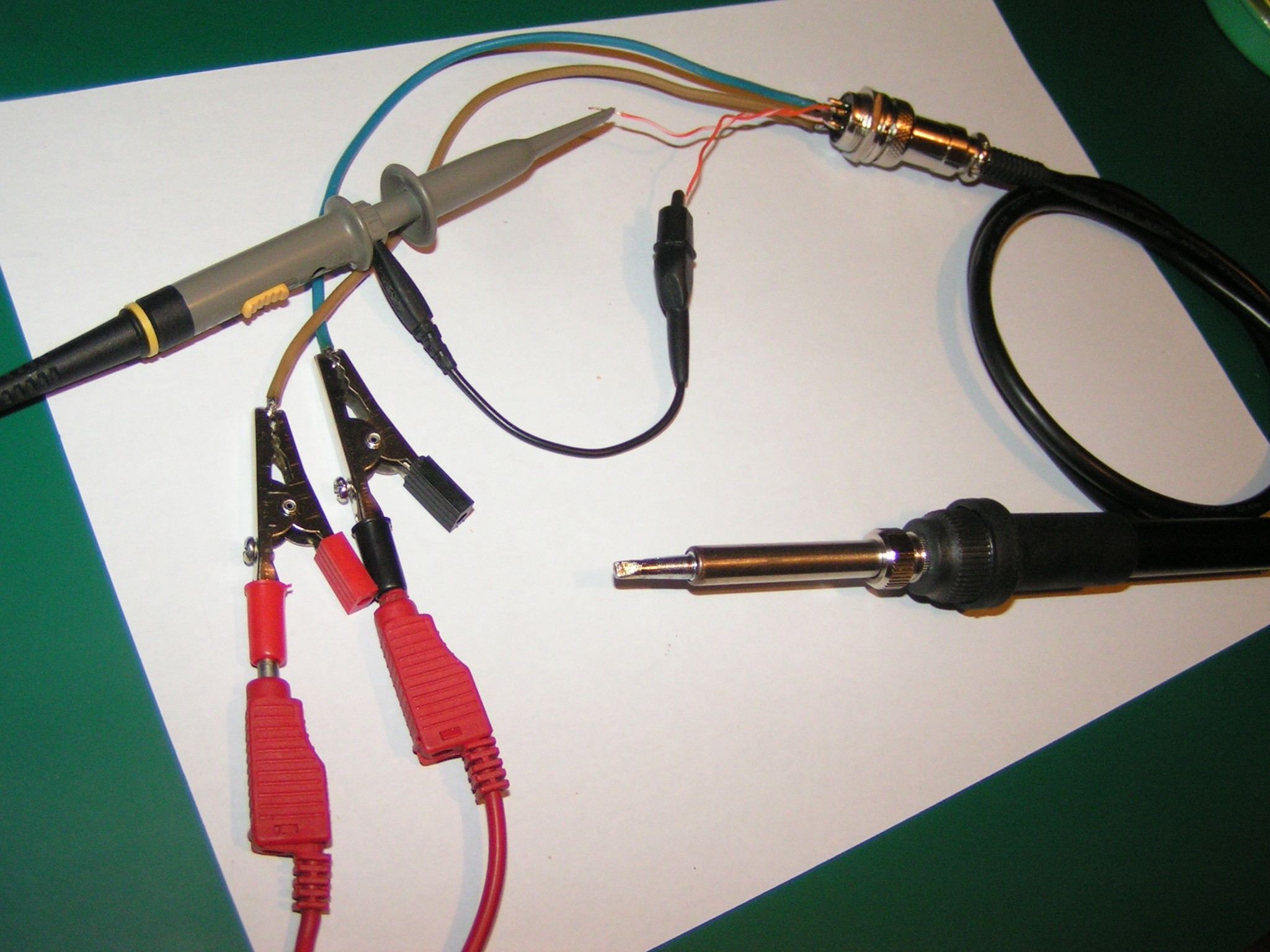

The oscilloscope probe is connected to the soldering irons thermocouple. The power source is connected to the heating element of the soldering iron.

How it works

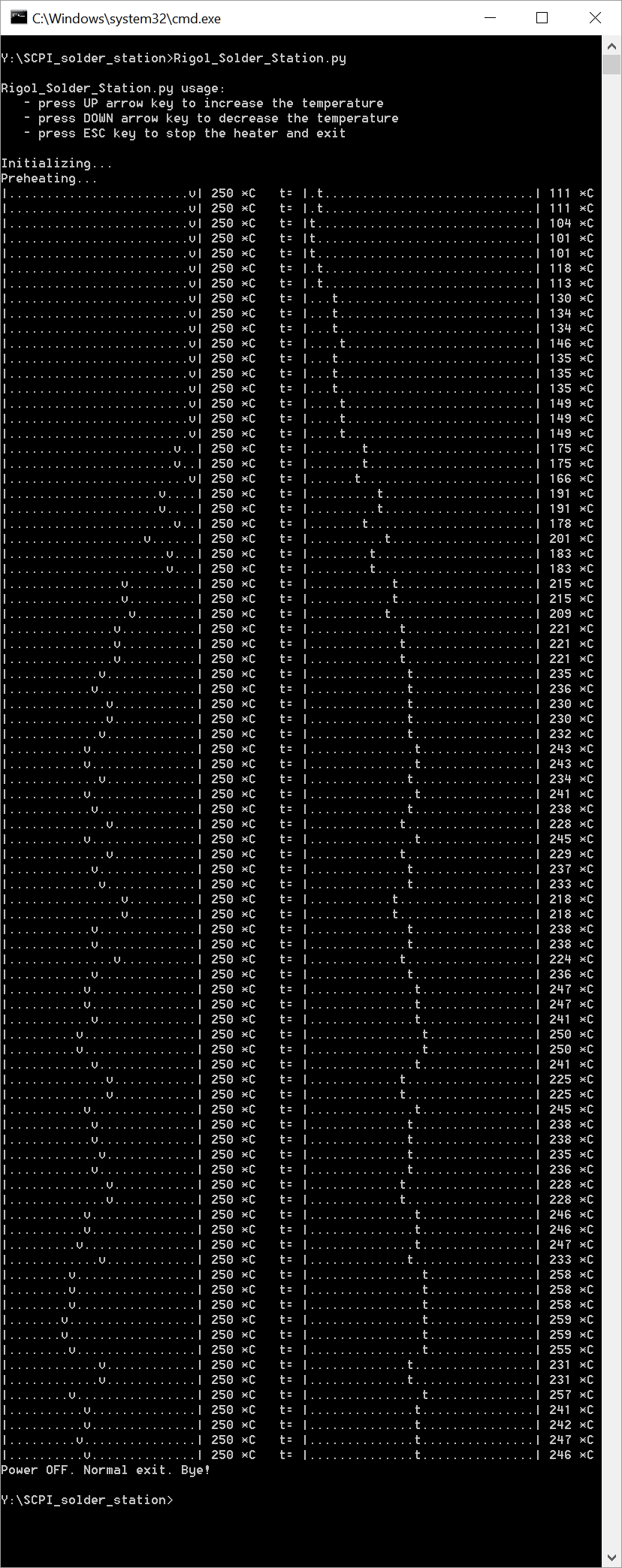

The PC runs a Python script that sends commands to the oscilloscope and to the power source, in order to implement a PID temperature control loop.

Temperature can be changed in steps of five degrees Celsius by pressing the Up/Down arrow keys. Python source code is available at https://github.com/RoGeorge/SCPI_solder_station.

The PC reads the thermocoulpe voltage from the oscilloscope, calculates the thermocouple temperature and sends commands to adjust the voltage of the power source that feeds the heating element. The temperature is kept stable enough to make a first impression about the heating power of these kind of soldering irons.

This solution was implemented mostly for testing purposes, to see how well various soldering irons and tips performs. It can be used for real soldering too, but not recommended.

If something goes wrong, this setup might become a fire hazard.

Just in case you want to replicate it, do not leave it unattended.

Conclusions

- Does this setup works?

- Yes.

- Does these soldering handles needs a PID control loop?

- No. For 900M soldering tips, the sensor is too loosely coupled with the tip. The sensor is inside the heating element, so keeping the heating element at a constant temperature does not imply the soldering tip will stay at a constant temperature too.

- Can the tip temperature be properly calibrated?

- No. The handle temperature can easily vary within 10-20*C from the room temperature, but there is no cold junction compensation for the thermocouple inside the handle. Assuming you measure the room temperature, and the sensor is perfectly coupled with the tip, the temperature offset can still vary in a range of 20*C from the set temperature, depending of the handle temperature variations.

- Can these handles be used for occasional/hobby soldering?

- Yes.

- Can these handles be used for heavy work or precision soldering?

- No. The soldering tip arrives at the working temperature only 10-20 seconds later after the sensor temperature has stabilized, which makes any temperature control pretty useless. It seems that the 900M soldering is based mostly on the heat accumulated into the metal of the tip, but the temperature sensor is in the heating element, so the tip can not be maintained at a precise temperature during soldering. Also, no matter which tip model from the 900M series I choose, it can not provide enough heat to solder on a big ground plane.

Acronyms

RTD - Resistance Temperature Detector

PC - Personal Computer

LXI - LAN Extensions for Instrumentation

SCPI - Standard Commands for Programmable Instruments

LAN - Local Area Network

PID - Proportional-Integral-Derivative

RoGeorge

RoGeorge

Carmine Moleti

Carmine Moleti

Daphne

Daphne