After having basic project decision made and verified, I designed two kinds of 3D printable sensors. The most vital parts of sensor are the ones I mentioned before - flexible material, fiber and pushing rod, but I also need body that keeps it together, keeps pushing rod perpendicular to fiber and returns it to "zero position".

Flexible sensor

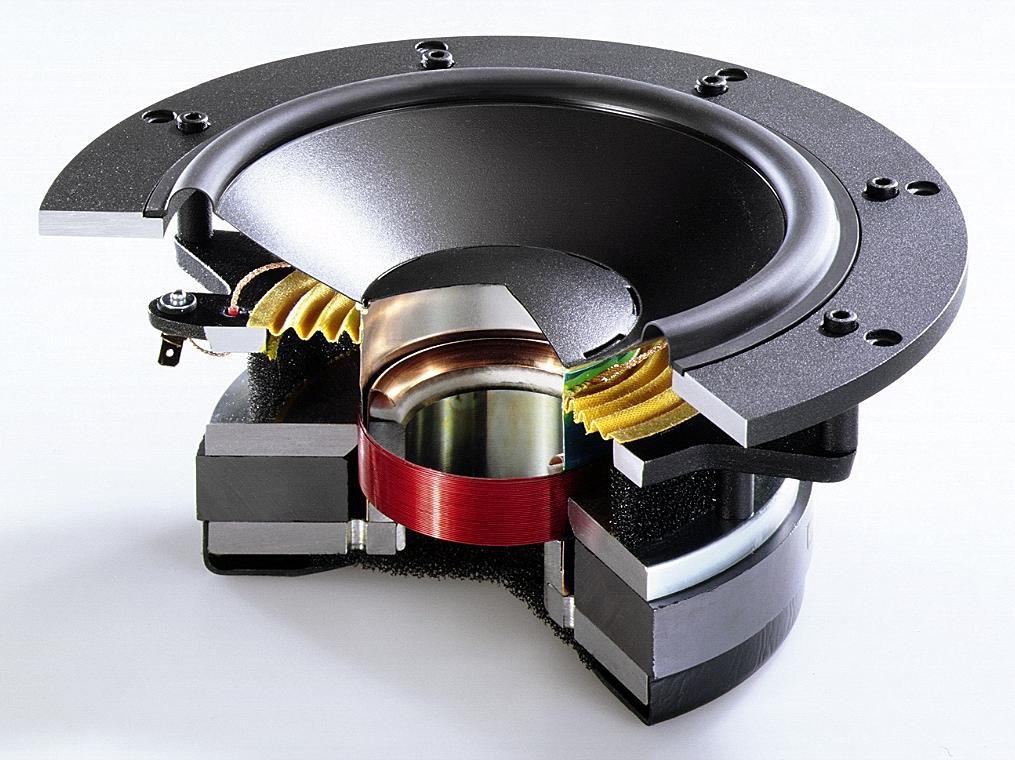

I took an inspiration from loudspeaker suspension design (the wavy yellow part)

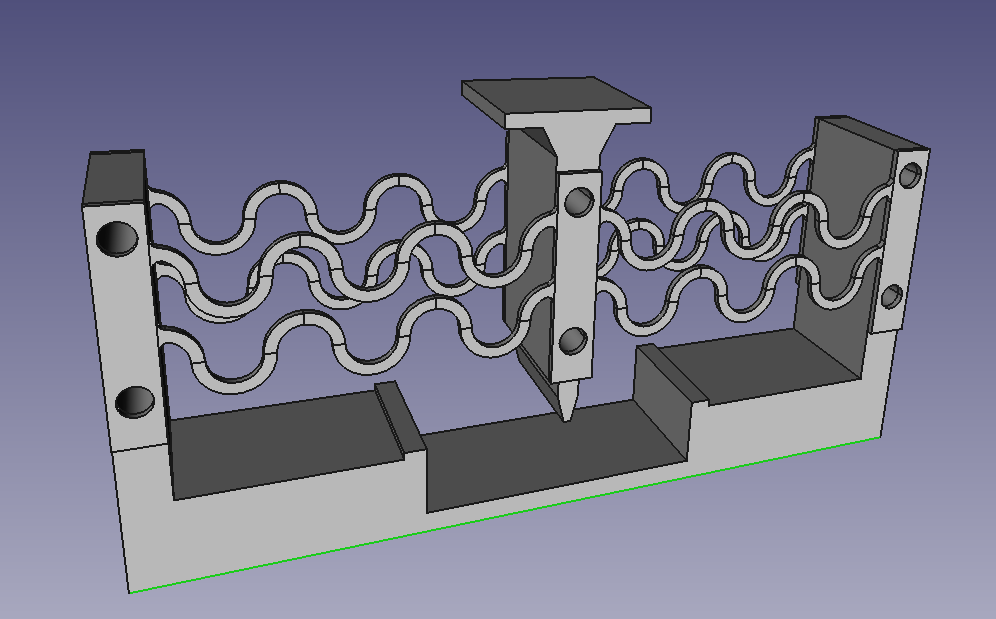

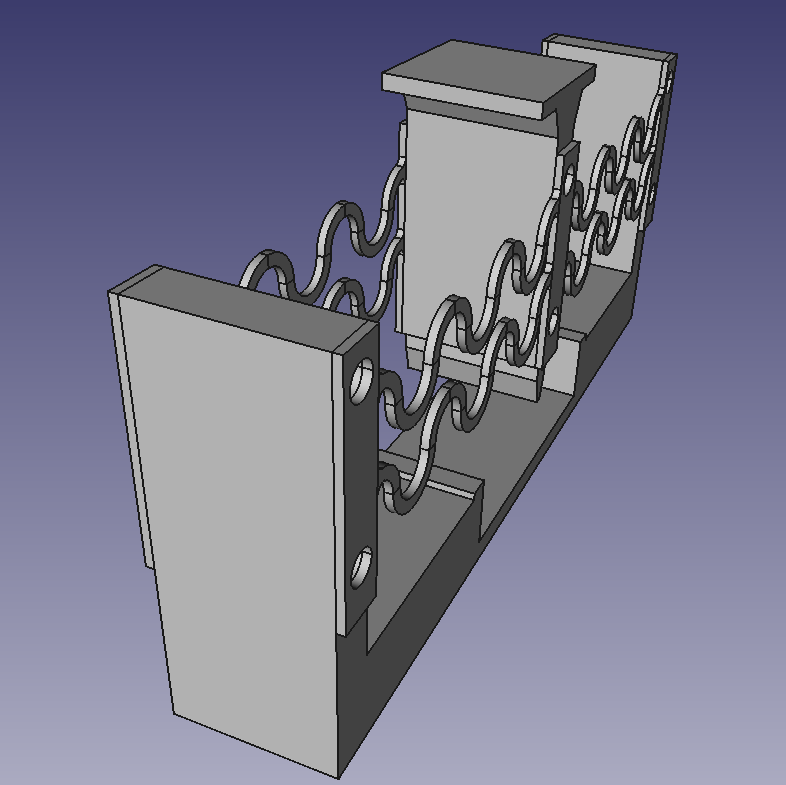

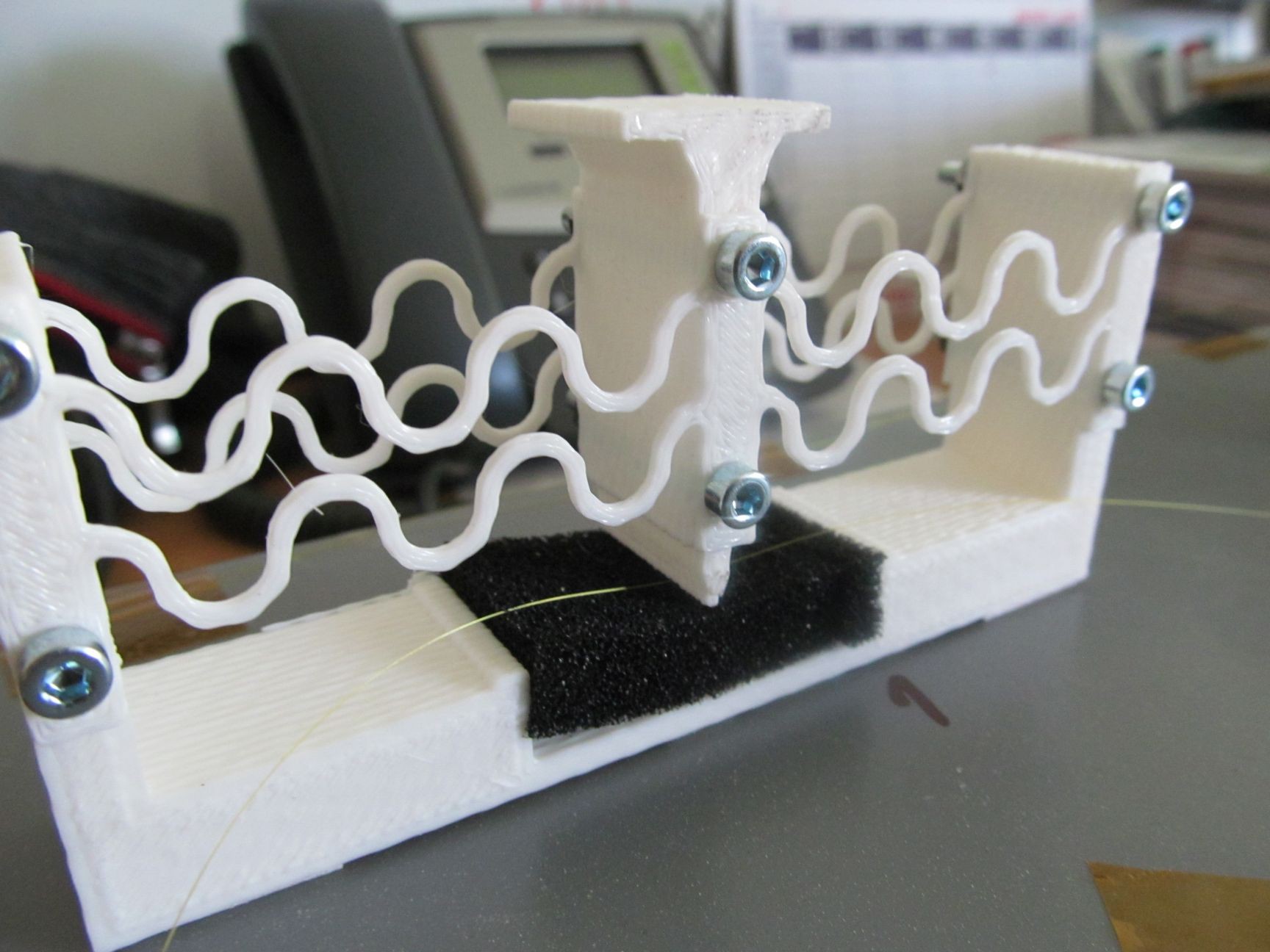

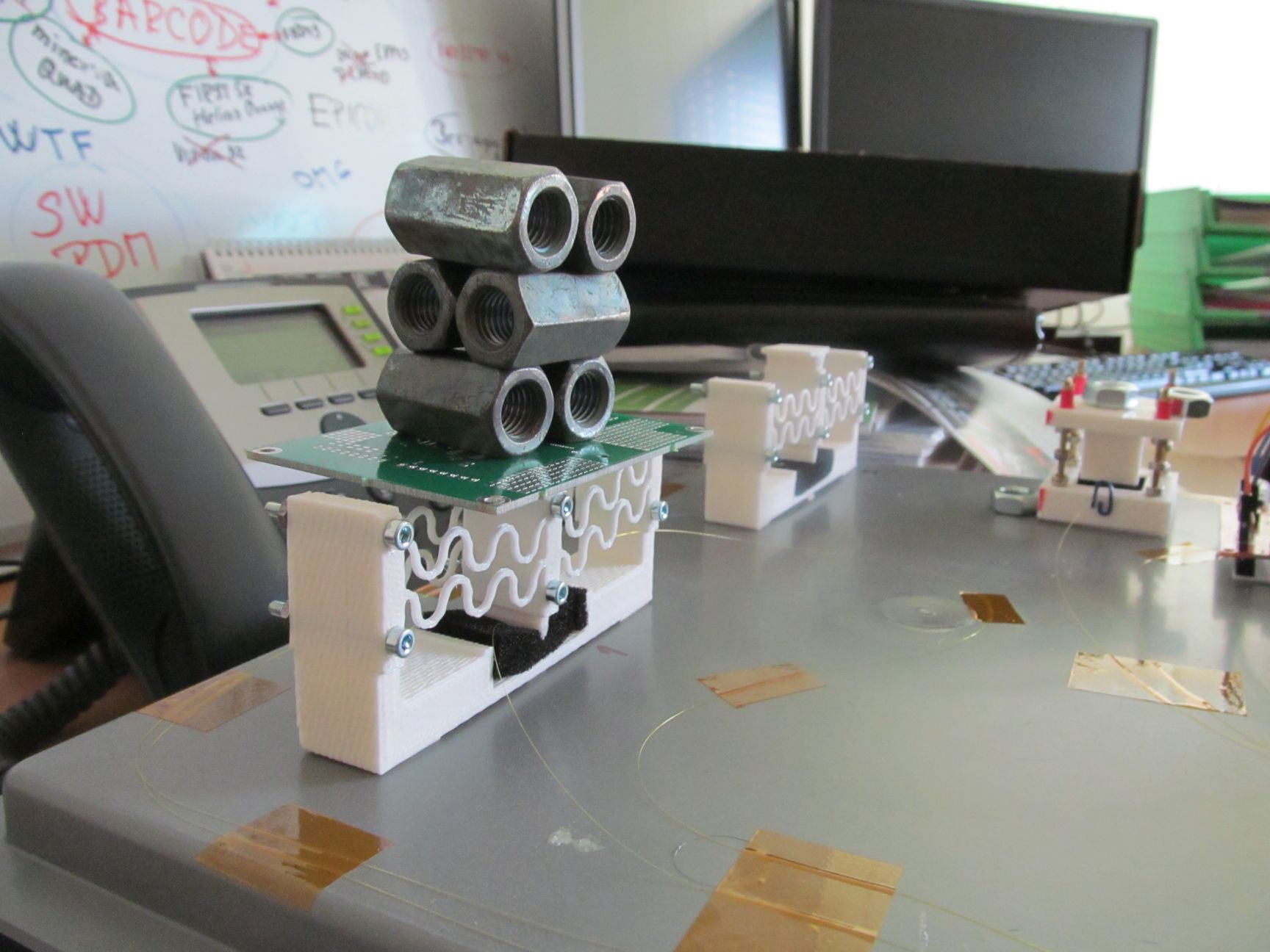

This sensor takes advantage of flexibility of plastic to allow pushing rod movement.

This sensor takes advantage of flexibility of plastic to allow pushing rod movement.

or in slightly different view

or in slightly different view

It's made of three different kinds of 3D printed parts, in order to keep it simple and printable on average home printer.

It's made of three different kinds of 3D printed parts, in order to keep it simple and printable on average home printer.

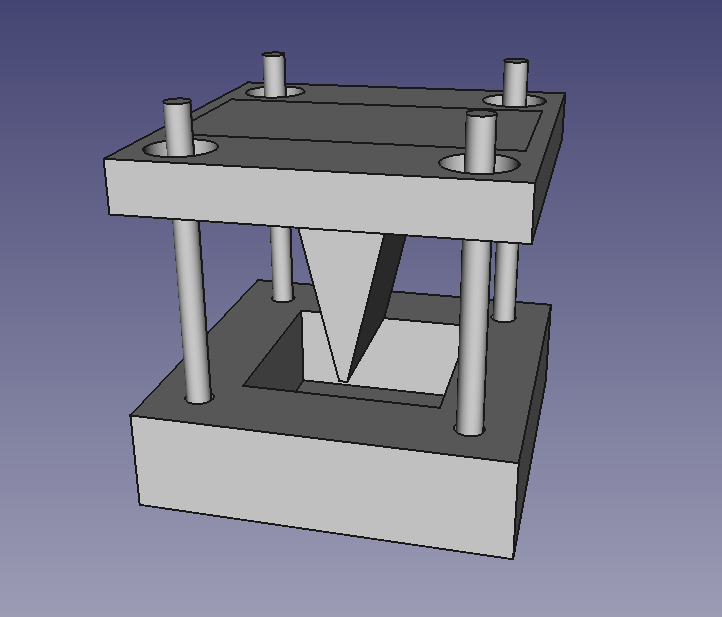

Suspended sensor

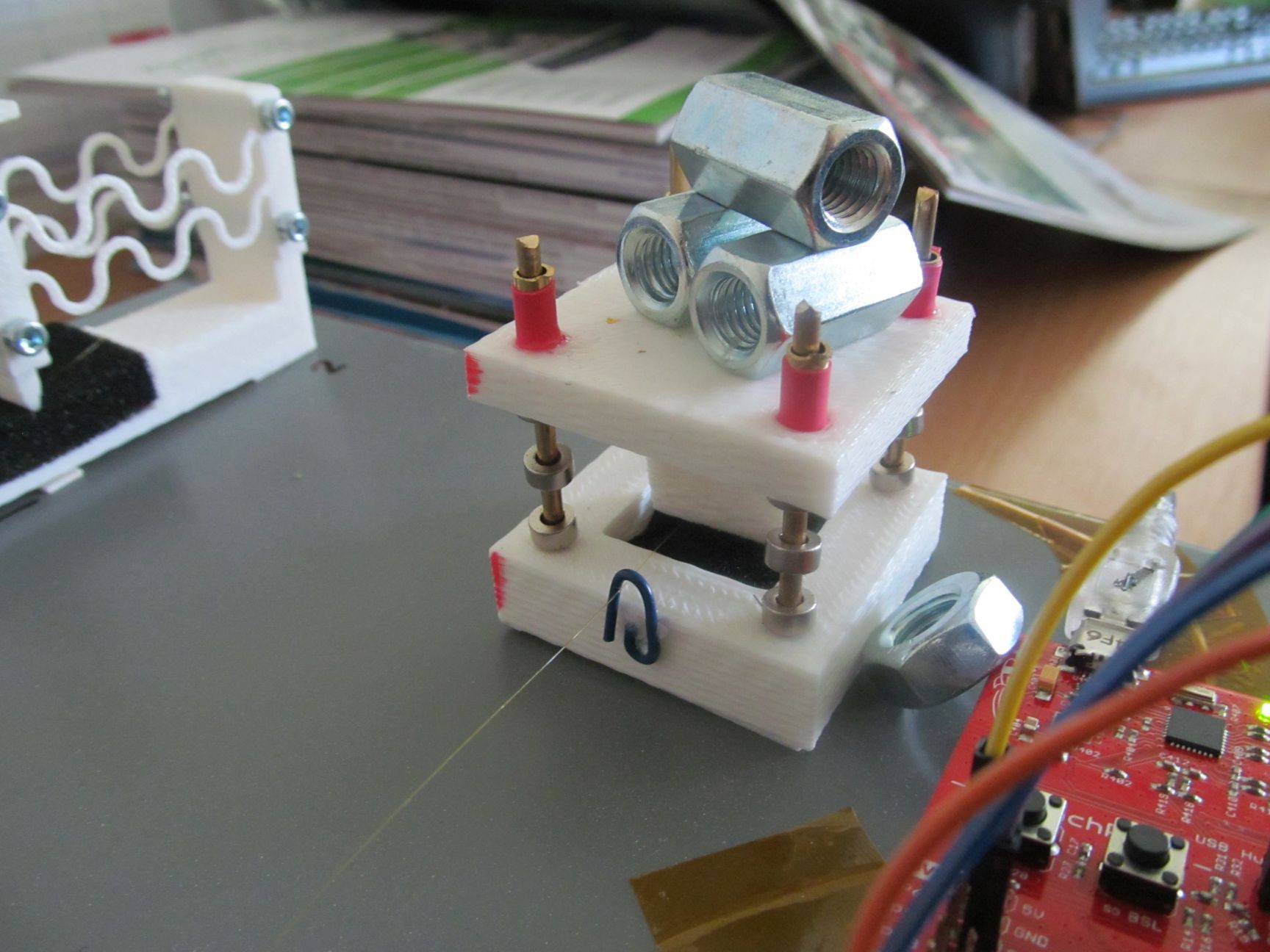

Unlike first one, this doesn't use flexibility of plastic, but steel springs were planned as suspension. Sensor has smaller footprint and is smaller/faster to print.

Suspension is to be added on the four pillars, leading upper part with pushing rod against flexible material in empty space in bottom part.

Suspension is to be added on the four pillars, leading upper part with pushing rod against flexible material in empty space in bottom part.

I realized this is good project to use magnetic springs - hollow magnets stacked on non-magnetic pillars, with alternating orientation to keep them repelling. I spent a minute playing with this toy

I only had 2,5mm OD brass bar, because that was what I had available. The magnets do have 3,2mm ID, so 3mm bar would be better fit.

I only had 2,5mm OD brass bar, because that was what I had available. The magnets do have 3,2mm ID, so 3mm bar would be better fit.

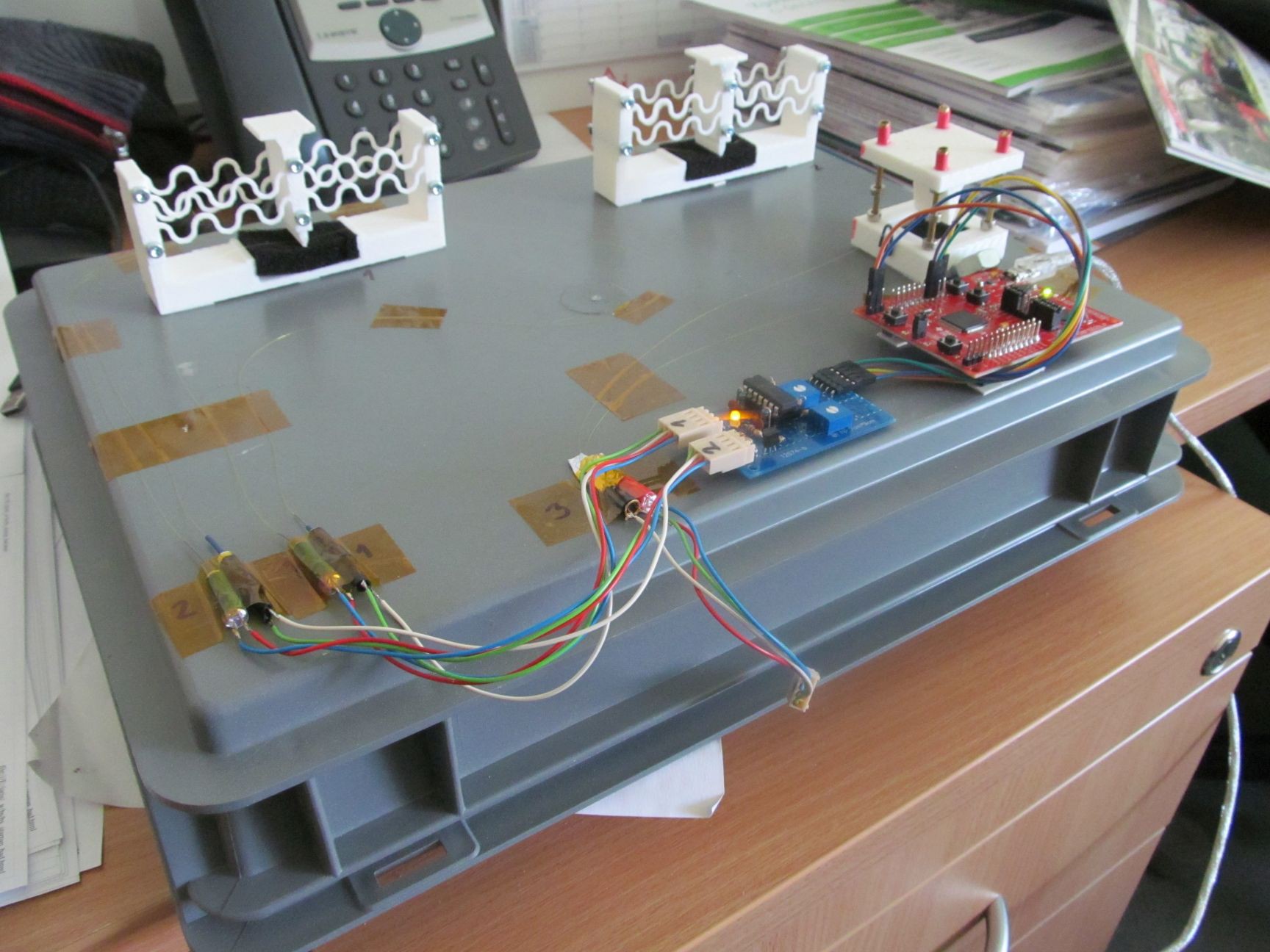

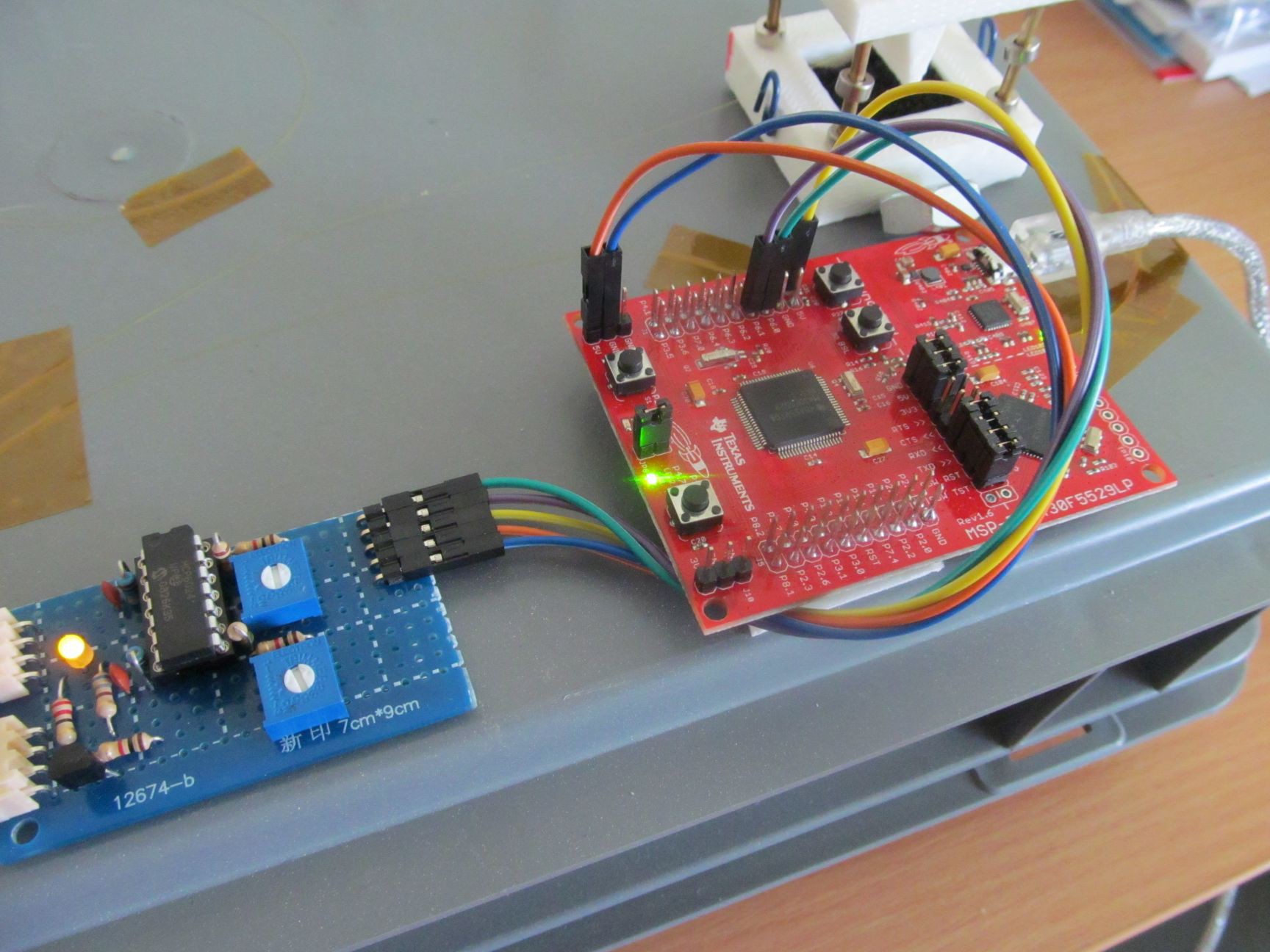

As I was printing the sensor parts and assembling them, my desk was getting tangled messy heap of cables, fibers and tools, so I made project board by turning shelf container upside down, all items are tacked by double sided adhesive foam tape - because, well, this is hackaday.

Detailed view on flexible sensor with no load...

No fiber optic sensors were harmed during making of this project. In future project log, I'll take a look at results and how I measured it.

No fiber optic sensors were harmed during making of this project. In future project log, I'll take a look at results and how I measured it. jaromir.sukuba

jaromir.sukuba

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.