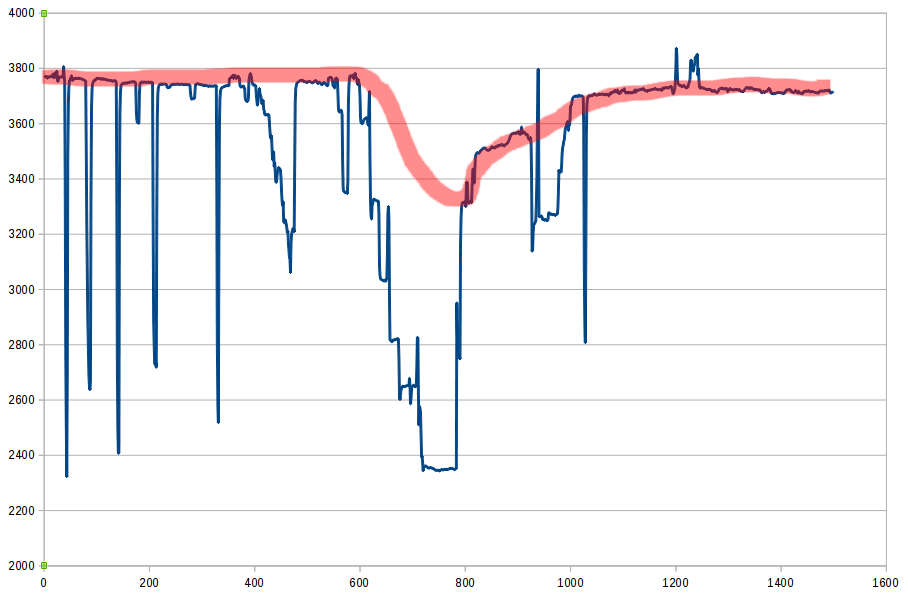

I'm glad the first idea, followed by three prototypes of two designs worked as I envisioned, including possible problems. Both designs do need flexible material under the fiber - and this material should be really flexible and return to its previous shape after force is gone, Unfortunately, the pieces of black foam I used aren't the best in this characteristic and it somehow remembered its deformed shape. You can see it on this longer-term (roughly 6 minutes) graph

Blue line is sensor response, I added red line showing how zero of this sensor drifted after full load test, slowly returned to original value, but never really got there. I'm pretty sure there are better flexible materials than random black foam I found in my drawer, perhaps latex or something.

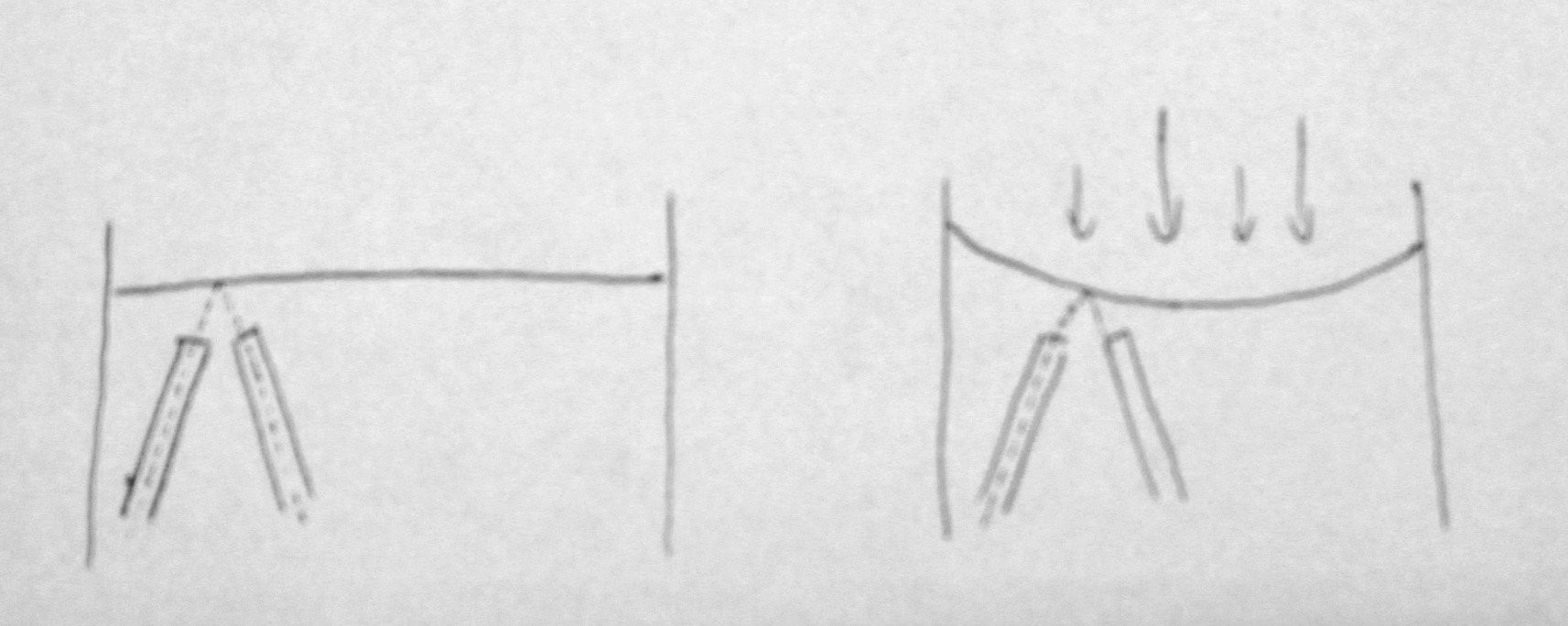

Also, I thought of different designs, like pressure sensor

There are two fibers under reflective diaphragm, aligned so that light coming out of one fiber is reflected into second fiber. As pressure is applied to the diaphragm, it bends and light is deflected from its ideal path, so receiving fiber gets less light and dip in output light power is detected. As the light coming out of fiber is refracted, the slope of sensitivity (that will depend on clearance of fibers to diaphragm) will allow linear operation, at least in some region of pressures. Because fiber is not bent here, POF would be good candidate for such as application.

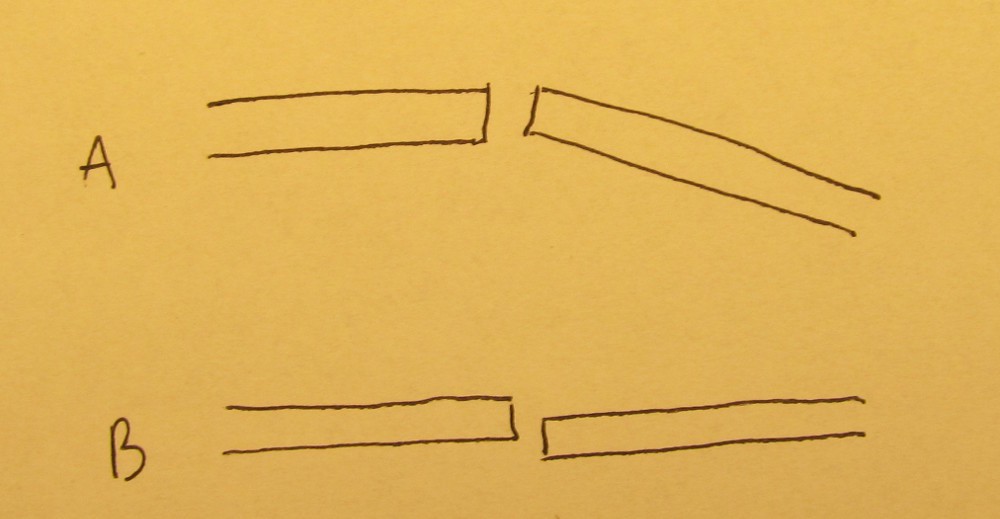

Another design would utilize two fibers, aligned coaxially, with small air gap between them. If the fibers will be misaligned now, either by changing the angle to something other than 0 degrees (situation A on picture below) or offsetting them (situation B), losses in this device will increase again, easy to be measured. Funny how @Ted Yapo had the same idea.

In both those designs, the measurement principle is not based on extreme bending of fiber, so cheaper and more common POF could be used here.

jaromir.sukuba

jaromir.sukuba

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Just adding some more ideas - the pressure sensor can be used as microphone. It could have hundreds of meters long cable, with no hum pickup.

The second principle is reduced to element that is sensitive to displacement. You can do a lot of things with that. Glue it to piece of thin steel, you have weldable sensor to watch for stress in buildings and stuff. Glue it to magnetostrictive material, there you have magnetic field sensor. Glue it to anything with different temperature expansion coefficient, you get thermometer.

Are you sure? yes | no