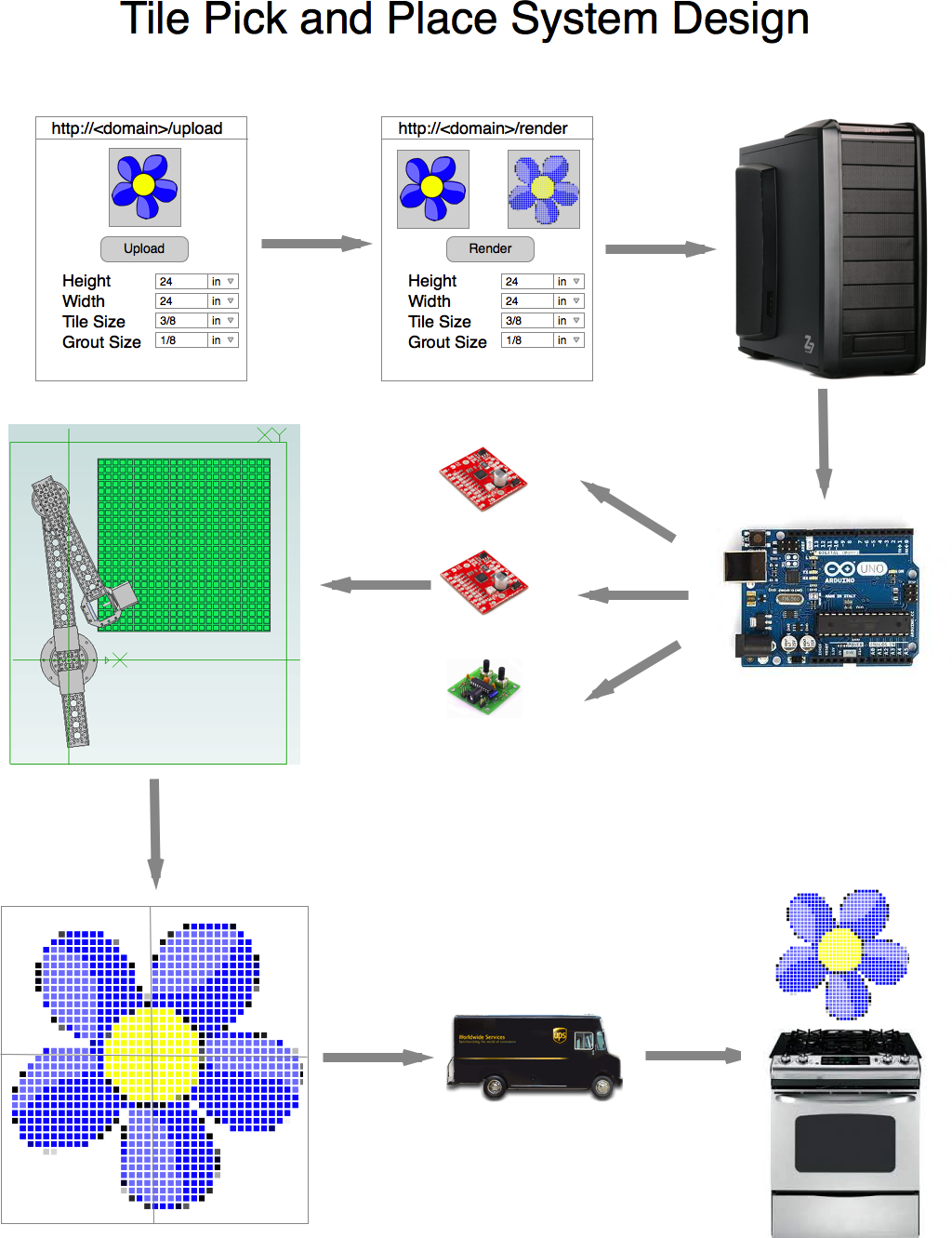

System Design -

- A user uploads an image to a server

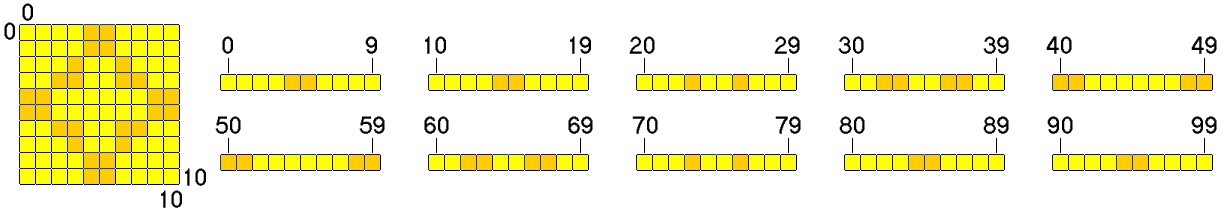

- The user specifies the height, width, tile size, and grout line size and manipulates as necessary to get the image to look good tiled

- An order is placed and the design is downloaded to a local server

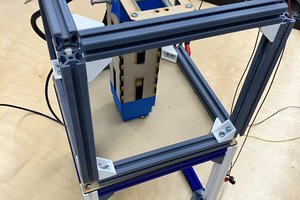

- The local server divides the image into 12" x 12"

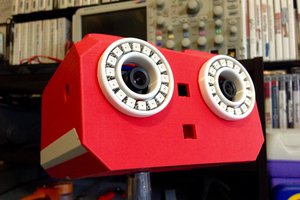

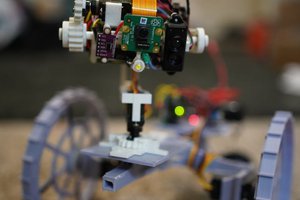

- The local server uses a camera mounted on a scara style arm and open cv to select a tile and place it in order to build up the image

- An arduino with big easy stepper drivers and servo drivers moves the arm

- A preview of the sheets is emailed to the customer

- Accepted sheets are shipped out to the happy customer!

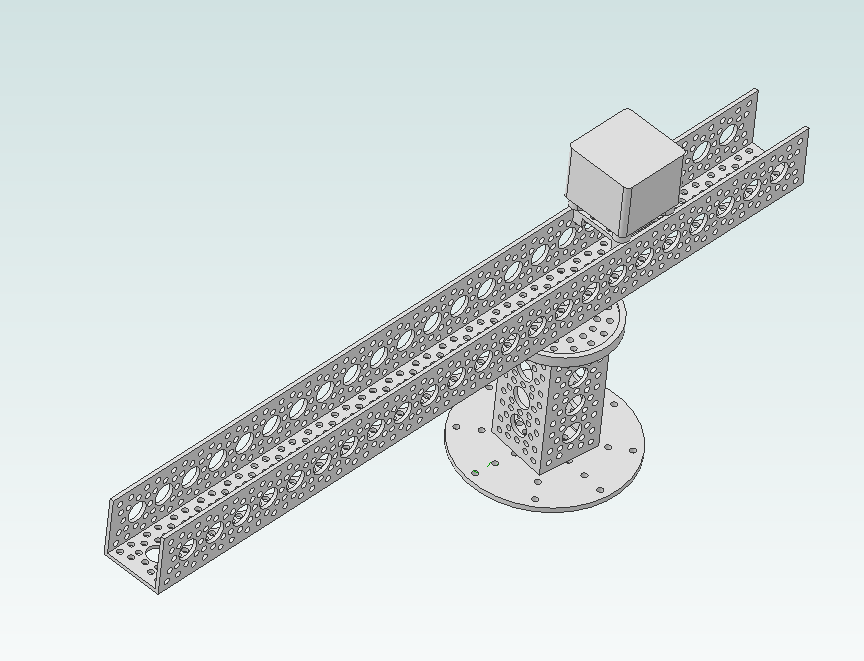

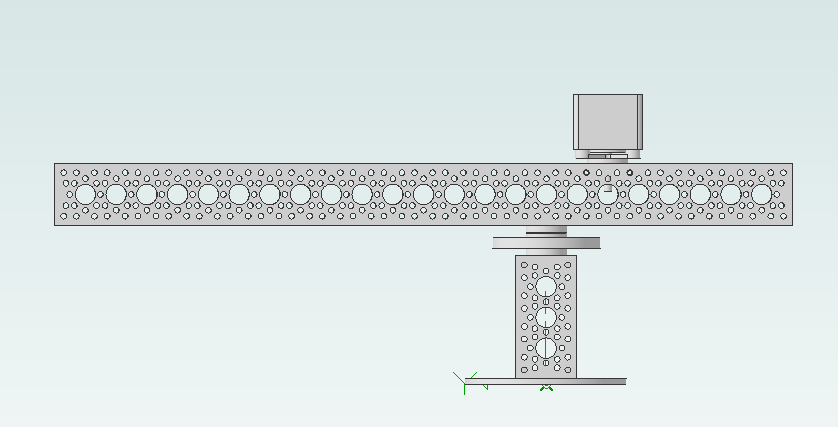

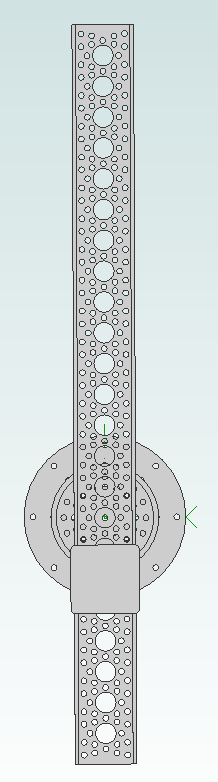

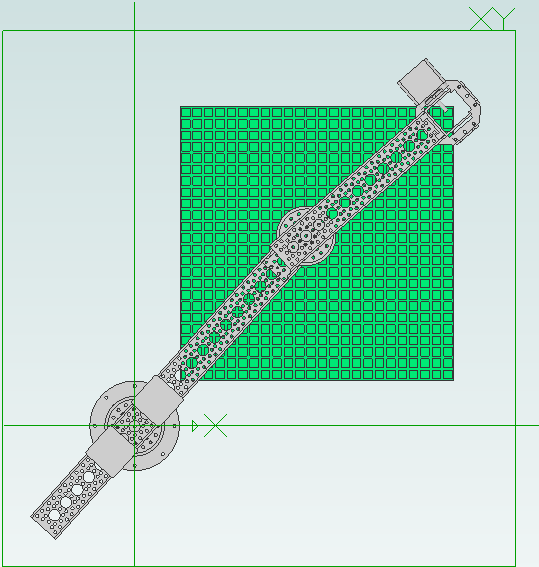

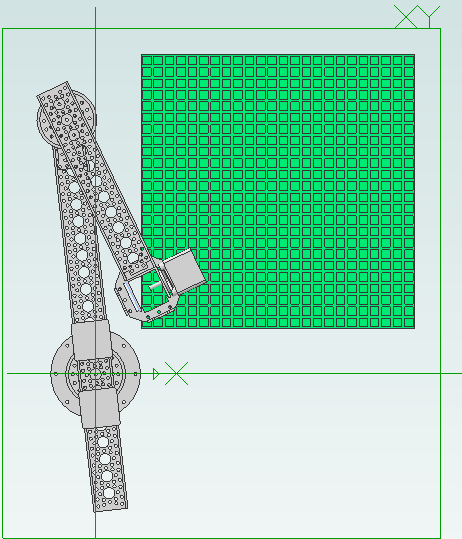

SCARA Arm Minimum Reach

SCARA Arm Minimum Reach As you can see in the minimum reach image I need to make the second arm longer in order to get the last few tiles into place. One of the really nice things about using a SCARA robot is that I would essentially have 4 quadrants to work in. This means that I could either do a few fields of source tiles and a few sheets at once or any combination thereof. I'm concerned that the arms may not be stiff enough, especially since I haven't defined the end connector yet.

As you can see in the minimum reach image I need to make the second arm longer in order to get the last few tiles into place. One of the really nice things about using a SCARA robot is that I would essentially have 4 quadrants to work in. This means that I could either do a few fields of source tiles and a few sheets at once or any combination thereof. I'm concerned that the arms may not be stiff enough, especially since I haven't defined the end connector yet.

ThunderSqueak

ThunderSqueak

peter jansen

peter jansen

Jacob David C Cunningham

Jacob David C Cunningham

Dan DWRobotics

Dan DWRobotics

Don't forget to keep updating as you move along with your project - the more information the better!