Every single component of the boat is thoroughly tested before implemented in the design. Here I will talk about the most important recent results.

PID Controller Testing

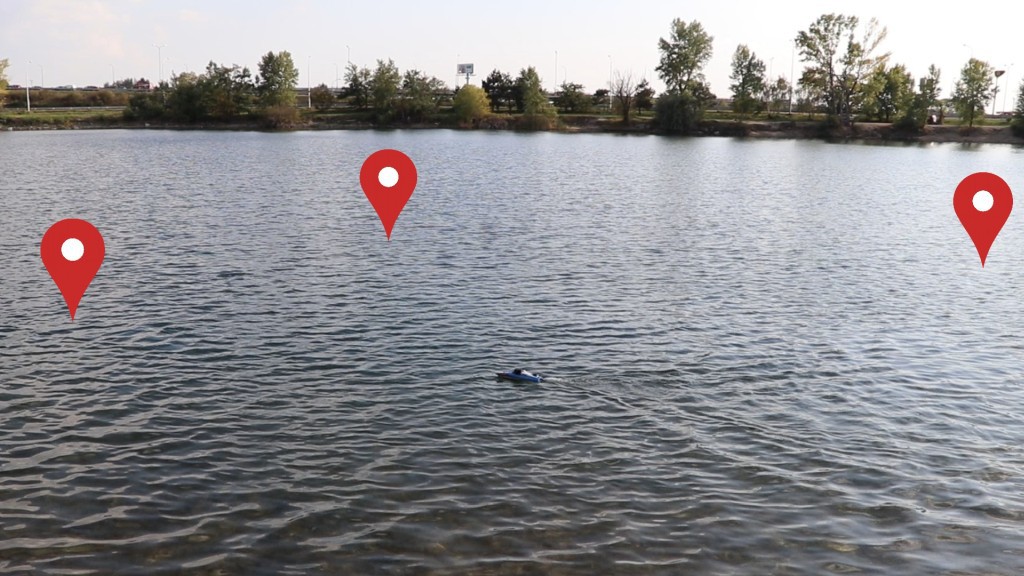

PID controller is a computer algorithm that takes into account immediate compass and position changes while steering, so the boat keeps its heading in a straight line.

https://en.wikipedia.org/wiki/PID_controller

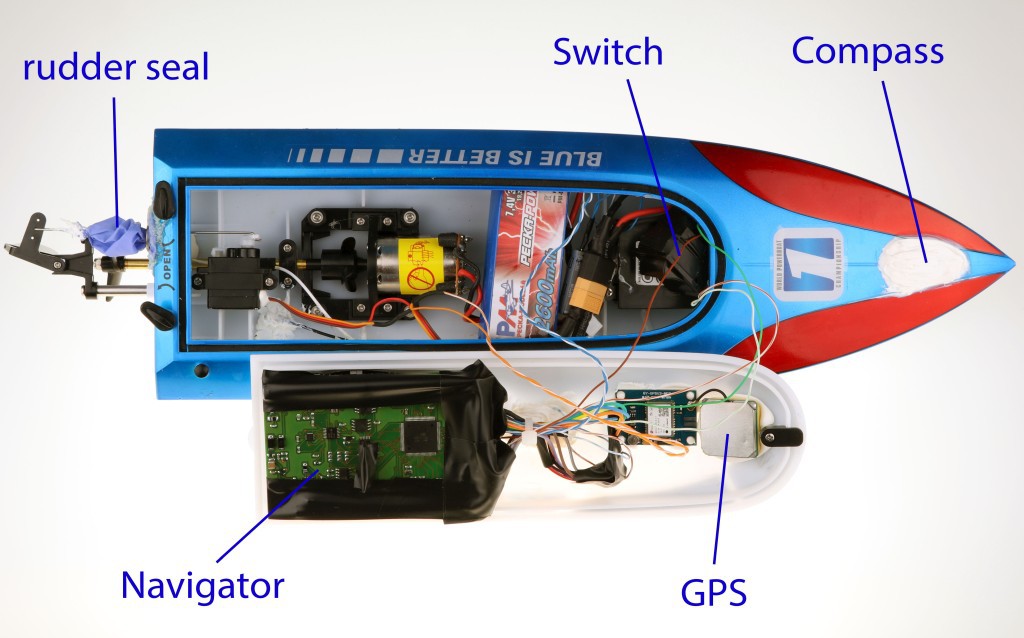

Stability at high speeds would be difficult to test with a sailboat as the winds in the middle of the ocean can be much stronger. Therefore, a hobby RC boat has been converted to autonomous boat to fine-tune the PID controller working at high speeds.

Servo Testing

The most common issue in the previous transatlantic attempts is rudder failure. If we expect a rudder moving every 3 seconds for a duration of 6 months, this makes over 2.5 million cycles! That's more than any servo manufacturer can guarantee (besides some very special and expensive products for medical applications).

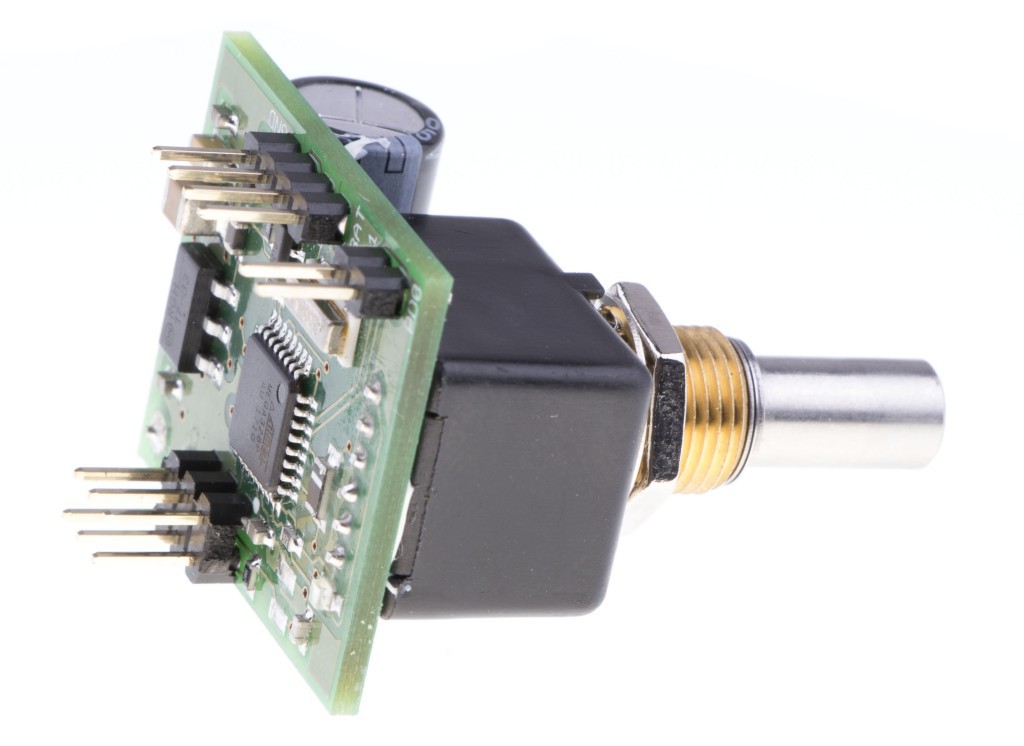

I have been testing a cheap worm drive sold as JGY-2838 connected to a magnetic encoder EMS22A as seen in the video below.

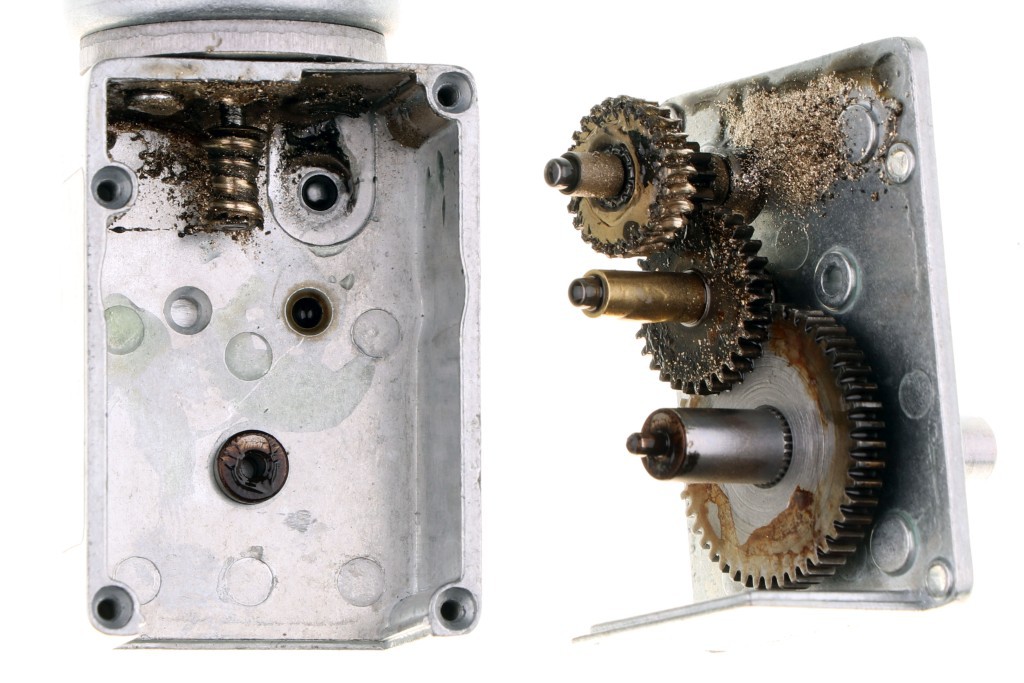

It's loaded with weight to simulate water resistance. The motor made over 3 million cycles under decent load until it failed. You can see in the picture that the worm gear is completely worn off.

It's not bad – it means about 7-9 months of continuous operation in the ocean which is more than the expected time frame (less than 3 months). There are two ways to improve it even further without much additional work:

- Add extra lubricant into the gearbox. Experts say that the worm won't wear off as long as it's properly lubricated. It starts to wear off very quickly after the lubrication fails.

- Steer less frequently. If the boat corrects its heading every 5-10 seconds on average, it can function for over an year or two.

The motor will be controlled by a separate Arduino-like PCB connected to the encoder:

Source code:

https://github.com/OpenTransat/ServoEncoder

Hatch Testing

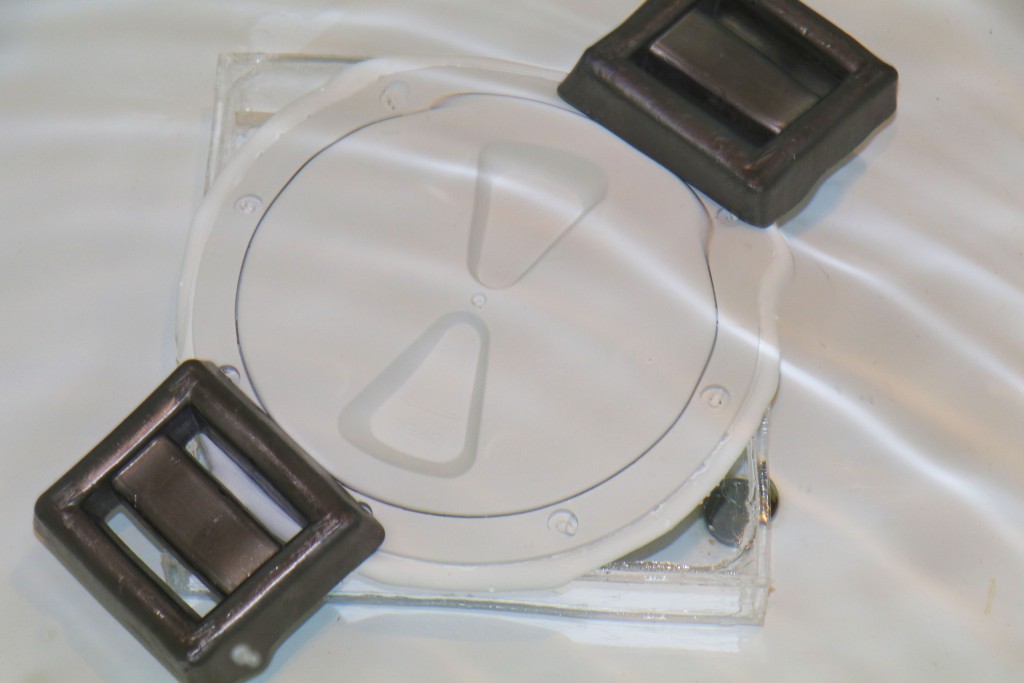

The hatch can be opened in order to access the electronics and it has to be perfectly watertight. The hatch in the picture is from a yacht shop and has been mounted on acrylic “aquarium” for testing. It was left underwater for 7 days and there was not a single drop of water inside the aquarium.

To compensate the air pressure inside the hull (remember that the air expands during hot days and contracts when it cools down at night), a Gore membrane vent has been fitted on the hatch. The Gore vent is a little magic that allows air to pass through the membrane, but it doesn't let any water in. Again, it has been tested underwater for a week.

Andy Osusky

Andy Osusky

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.