3D Printed Robot Actuator

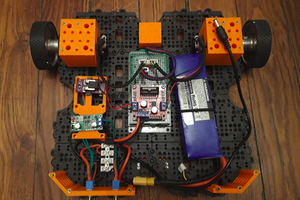

A high speed and high torque robotic actuator using low-cost brushless motors, custom controller, 3D printed parts and bearings.

A high speed and high torque robotic actuator using low-cost brushless motors, custom controller, 3D printed parts and bearings.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Leg.zipRepaired Pack and go file for SEA legx-zip-compressed - 28.52 MB - 04/24/2019 at 16:48 |

|

|

WS3.cywrk.Archive02.zipPSOC4 Project files Hardware and software (code) files More CAN comms and move instructionsx-zip-compressed - 1.76 MB - 10/23/2018 at 16:28 |

|

|

tail.zipFull Tail CAD Files Inventor Pack and Gox-zip-compressed - 21.73 MB - 10/21/2018 at 17:40 |

|

|

6807_tail.stpFull Tail Step Filesstp - 3.93 MB - 10/21/2018 at 16:28 |

|

|

6908_LEG.stpFull Leg (with SAE) Step filesstp - 5.83 MB - 10/21/2018 at 16:23 |

|

41:1 Dual Disk, Single stage

27mm x 102dia QM4208 motor, 6809 Bearing

Before Cycloidal Gearboxes, I research Concentric Magneti Gearboxes.

I made an improvement on the current design by drastically reducing the flux path length and hence increasing the torque handling ability.

standard flux path

New flux path

1x Brushless motor with extended shaft (6mm Silver Steel)

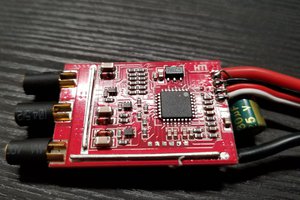

1x Custom Brushless Controller Board

2x AS5147 Absolute Position Boards

2x 6mm x 2.5mm Diametric Neodymium Magnet

12x 3D printed parts

16x 5x8x2.5 bearings

2x 6809 Bearings

5x 12x18x4

1x 6x10x3

8x 3mm dia x 30mm Silver Steel shaft

26 (or 13) 3/32" x 28mm Silver Steel shaft

26 (or 13) 1/8" x 16mm Brass tube (thin wall)

24x M3 bolts

10x M2 Bolts

3x PZT screws

1x M6 thin wall washer

1x 2mm dia x 11mm Silver Steel shaft

Suppliers

Favorite Makers

Create an account to leave a comment. Already have an account? Log In.

Your actuator looks good. Go to Discord->Odrive->robotics. Others are making this actuator in metal. I plan on running this on 8S (32V) MOSFETs are rated at 40V. I'm hoping for 20Nm with the 5010 motor. I'm looking at the 6215 Brushless 170KV.

I have just made a jumping stand for one leg. I haven't added the spring feedback sensor yet. I am trying to work out how to store the spring energy.

The more I work with SAMD21 (Arduino) and STM32fxxxx the more I like the PSOC4. If you are going to redesign the board, you should use the drv8323 instead. It is much better and has in integrated buck reg. I have started a design/PCB with it. Let me know if you want to see it. (What software are you using?)

I purchased a few AS5147 for testing last year. I am trying to find more but nothing yet.

I thought the 5010 was spec'd out at 6S 24v max? Maybe temperature dissapation is the limiting factor. In that case 32v sounds like fun.

I've been using KiCad. I grabbed Altium Viewer to get a closer look at your board. Electronics is a weak spot for me, but I can follow most of the datasheets and documentation. I'm using your Cypress codebase to learn PSOC creator.

Here's a sketch of what I have in mind. A circular board with an AS5147 mounted dead center, keeping the electronics close. No long SPI runs, just power and CAN to each actuator. motor shaft AS4187 mounted on a carrier board underneath. USBUART for pre-install configuration.

The 5008 is 6S max and the 5010 is 8S max but it is rated at continuous operation with a lot of air flow. The PSOC code needs to be tidied up, sorry. The round board looks good.

I've been using the AS5047 boards from massmind.org. However, they only sell assembled boards and not the ICs themselves, so I don't know if that's any use to you.

Yeah, looks like both the AS5047 and AS5147 are out of stock in the usual places.

Per Paul, the AS5601 isn't suitable.

There's also a MA700GQ-P that support SPI, but would require a carrier board change and most likely some code changes as well. Paul says that this one might work.

Great design! Do you have an estimate of the torque-to-weight ratio? I'm working on a similar project (https://hackaday.io/project/159404-opentorque-actuator) that puts out 56 Nm of torque and weighs 1.2 kg. I'm curious how that compares to the specs of your actuator.

The actuator weights 536g with all the electronics and cables. (Not including battery).

Theory - The Multistar 5008 330KV has a Kt of 0.029 (Nm/A). Max Amps = 27A and a gear ratio of 25:1 x 75% Efficiency = 15Nm

Testing - (As in the video) Lifted 3Kg at 330mm = 10Nm (Voltage and Amps need to be rechecked).

I haven't pushed it to hard yet and I only have 1/2 the external pins in. 10Nm is enough for my application. I am hoping the big quad i'm making with Series Elastic Actuators with be about 10Kg (including some light/small batteries and with minimal sensors)

I like those large high pole count motors. I wanted to use them but I would have to change my control scheme and not use the magnetic encoder (only works well at 7 pole pairs). I just read that you are using the AS5047 magentic encoder with O-Drive. How well does it handle 0RPM holding positions?

The AS5047 has been working perfectly so far. No issues with holding positions at 0 RPM. Currently I'm just using the incremental ABI interface, but I'm going to set up the absolute position interface so it doesn't have to search for the index pulse on startup.

I see you're using the AS5147. How come you say it's limited to working with 7 pole pairs? That sensor has a resolution of 2048 CPR according to AMS' website, which should be plenty for any high-pole-count motor.

In regards to the efficiency of your gearbox, have you measured it at 75% or is that just an estimate? 75% seems low for a single-stage cycloidal reducer. If you're having issues with sliding friction, I recommend printing the cycloid disks out of nylon. I used Taulman Alloy 910 for the gears in my design and they run very smoothly.

Gabrael - The data sheet of the 5147 says the the UVW interface support 7 poles pairs, so I assumed that it should only be used with 7pole pair motors for all the interfaces. I might be wrong on this and will have to do more research. I would like to use the higher pole count motors with a lower KV and higher torque and lower gear reduction.

Did you try any other motor? How long does the 9235-100KV take to spin up to full speed? What RPM are you getting?

I haven't measured the efficiency yet, I would rather underestimate. I don't think I am having sliding friction problems, it is all rolling elements. I have some Nylon but I have to upgrade my printer so that it can reach a higher temperature.

The 7 pole pair limitation only affects the UVW interface, since it outputs commutation signals for each of the motor phases. Since you're doing the commutation from the microcontroller, you can use any number of pole pairs you want.

The 9235-100KV spins up really fast. See here: https://www.youtube.com/watch?v=0rMyaOB3w1Q

The max RPM should be 2400 (24 volts * 100 rpm/volt). I haven't confirmed this though.

These 9235 motors are great, by the way. They have so much torque you could use them in a quadruped with no gear reduction at all.

Your design is impresive! It got me to thinking about how animals and insects can jump so well. In biological systems that are "jumpers" (fleas, grasshoppers, kangaroos, even humans), the tendons are loaded before a jump, and then the "release" happens ... which basically adds a spring into the system. There are linear wound springs (like in a dog walking leash - but stronger!) that might be usable in your system. You would have to "pre-wind" the spring, and then trigger it. Given a strong enough spring, you could get some pretty decent "instant" burst of power from a "small" addition. You mention backlash; if you have rotational transducers, couldn't you just "fix" that with software? That might introduce too much delay, maybe. Best of luck, and keep posting! Between you and Mike's Robot Dog (see: https://hackaday.io/project/52956-mikes-robot-dog/discussion-108871), y'all are making me want to get a 3D printer, or learn to cast brass, etc!

I am working on creating a video of the parallel linked series elastic actuator that is on the big quad. I am trying to work out how to store the spring's energy on foot fall/ landing and release it later in the gait.

The backlash is quite small, it is the main reason I chose the Cycloidal gearbox design. It is more than good enough for e quad, maybe not for a robotic arm. I was after speed and torque rather than precision.

Hey Paul, I've been really studying your actuator model, and I have a few suggestions that I'm incorporating into my build. The rest of my parts should be arriving next week. Here's a link to my work in progress model: https://a360.co/2yxWgQO

- If you separate the eccentric lobes you can pin them separately during assembly. I'm pretty sure that having a single pin driving both lobes is going to be the weakest point at load. I'm also looking at 2mm v 3mm retaining pins.

- I've reduced the drive rollers from 8 to 6, and included 6 through hole bolts. The locknuts need to be trapped into the motor bracket earlier in the assembly. This should make the actuator much stronger. I'm on the fence between having 6 drive rollers and 6 bolts, or going 4 and 4.

I hacked together a parametric cycloidal gear box generator into Fusion 360, changing ratios is almost automatic by adjusting the parameters. I've been going back and forth between a 26:1 and 32:1 gear reduction for the Gartt 5010. Out of curiousity, what design software are you using?

https://i.imgur.com/29jmPCP.jpg

https://i.imgur.com/juXSZ5D.jpg

On the electronics side, I have even more catching up to do. How are things going on your next controller? Depending on how invested you are in your SAM D21 design, the stm32f103c8 may be another option. It's what's used in the "STM32 blue pill" board. They're cheap, fairly well supported, and include CAN as well as a bunch of other features.

Hi Alan, Adding the bolts is a good improvement. Just be careful you still have enough material at that diameter so that it doesn't weaken the gear. I tried to replace the 3mm rods with M3 bolts with a long shank. I had some problems getting the alignment correct. (It also took along time to take the unit apart).

I have just created a parametric cycloidal gear in Autodesk Inventor (All my CAD is done in this program, I have it on my laptop for my day job).

Have a look at the testing of the motors here http://build-its-inprogress.blogspot.com/2016/01/motor-characterization-for-small.html

This is main reason I choose the Multistar Elite 5010/5008. I am looking at Foxtech and Arris for their 5010 motors but I just searched the Gartt 5010 on ebay and they are 1/2 the price. mmmm

I got the SAM D21 up to the point where I don't like the CPU. The SPI only has a single buffer TX and RX and requires the DMA to use it properly/efficiently. I wanted to create an easy solution (Arduino) for brushless actuator control. I'm not sure if I can hide the DMA in an Arduino library. I have thought about using the STM32F3 family but the PSOC4 is just so good. The problem is that is too complex for most makers.

I have some STM32Fx development boards so I will see what i can up and running. The stm32f103c8 will still require the use on DMAs for the SPI unless I change the structure of the code/interrupts.

Hi! In your video you showed it pulling 10 Nm @ 12 V with a peek of 5 amps. This is with the Multistar elite 5008 & a 26:1 gear ratio, right?

I love the results, but am a bit confused. The 5008 is 330 Kv, which would be a Kt roughly 0.029 (Nm/A).

0.029 * 5 = 0.14 Nm * 26 = 3.75 Nm

Which is way under 10 Nm. Is there something I'm missing?

Hi MattB, Your maths is right. I have never done the Kt calc befre. Where did I go wrong?

The arm is ~330mm between the centre of the 3kg weight and the pivot point. The battery is 3 cell Lipo ~12V. The cheap current sensor from Hobby King max value shows ~5Amps. I would guess that the filtering / averaging / update rate of the current sensor is not showing the actual peak. Is it the measurement Amps RMS?

I wonder what the efficiency of the cycloidal gearbox is. I would be surprised if it was over 80%.

Hobbyking claim that the KV is 330. I should be able to check this. Does the KV change as the speed approaches 0RPM/stall?

Does the Saddled Sine wave output of the controller give a different reading than a normal sine wave. Could this effect the Kv and Kt values?

As the arm moves from Vertically down to horizontal the torque required will increase. Maybe it is better to use a large pulley with a weight as this torque will be constant.

I will set-up the test again with better equipment and post the results. It would be nice if the theory matches the actual.

Hey Paul, this is an outstanding project, and congratulations on your win!

For the parts that require you to center them, it would be a snap to design and print a centering spacer to use during assembly.

I've been eyeballing the failure modes, and I think the first part to fail at load will be the eccentric bearing lobes. That's based on the stresses between the top and bottom lobe and a single eccentric bearing pin, which I assume is going through the center of the top lobe. Maybe sticking a second pin through the center of the lower lobe would help mitigate that?

And, did I see that you can backdrive the actuator? I wouldn't have expected that.

I have to admit that I've watched this video about 12 times already to understand how you've accomplished this. I'm looking forward to building a couple of these to see how they work.

Aliexpress would be a great source for most of the parts like the bearings, bulk 2mm x 28mm steel dowel pins, and 3mm (2.6mm internal) brass tubing. the 2mm pins are a bit smaller (15%) than the 3/32". Do you think those will work? Otherwise there are other sources for true 3/32" x 1 1/8" steel dowel pins.

Can you share a bit about the modified axle/shaft? Did you fabricate it? Or is that something that can be found and ordered online?

Hi Alan, I tried to put a second pin in the eccentric top lode but the "order of assembly" did not allow it to happen (unless I press fit the motor on the main shaft after assembly, this was not going to happen). I get silver steel rods from minitech and the brass tubes from the local hobby shop. I always buy local if I can get the right part (no matter what the cost) and only order overseas if I have too. i prefer to make parts from scratch if I can. Hacksawing a rod and filing the ends are easy to do.

The main 6mm shaft is a silver steel rod from https://www.minitech.com.au/. i just file a flat spot for the motor's bell grub screw and drill a 2mm hole for the pin at the right distance for the second lobe. I don't have many tools. (Cheapest 3D, cheapest drill press, cheapest vice and files and that's it). I can use my vice as an arbor press. I pressed out the motor's original shaft and pressed in longer 6mm silver steel shaft

Can the actuators be backdriven? I suppose if you want it to stand passively, you would not want that, bu it seems like putting the bearing in, on at least the interior pins, could greatly reduce internal friction.

Since your external pins touch two of the cycloid rings at once, would bearings not help there? Your cad odel appears to have bushings over the exterior pins, but i feel like they might have the same issue.

Backdriveable actuators are especially nice when you want to do force control, or try to map motor current to torque, which might be useful when trying to make this robot walk or jump.

The Actuator is backdriveable. It is only a 26:1 ratio. I think that having it backdriveable with regenerative capabilities is a must for overall efficiency. I had a prototype with bearings on the outside pins but the reduction ratio was lower because of the bearing spacing around the circumference. Also that is a lot of additional bearings, which increases cost and weight. Series Elastic actuator is also much better for efficiency (the big quad design has this). I am also trying to work out how to store potential energy from the elastic actuator (spring). Store the energy on a foot fall and release when going to jump/step.

I saw a project recently that used an atmospheric pressure sensor (very small) wrapped in a rubber material. When the rubber touched a flat surface the pressure on the sensor was registered. Made for a really quick contact sensor for feet. Might be useful for your quad walker.

That is a nice idea but it will only tell you after you have hit the ground. It would be nice to know just before then so that you can turn off the motors so the joints are a bit "softer".

how about... if the motor senses resistance and the foot is not touching then we know it's not ground interference. not sure what the logic branch from there would look like, tho it's an interesting edge case...

The sensor deforms make contact before the leg reaches all the way down and transfers its full weight. It is like the pads and hairs on the bottom of a cat's feet can provide feedback for the cat to walk quietly. Or your keyboard keys making contact before it reaches full stroke.

Pressure can travel, so the sensor doesn't need to be where actual impact happens;

Maybe just to re-state one point. I had the idea that a motor controller should live INSIDE a length of the 25x25 tube.

I had a robot fire a year of so ago. I has dumb and THOUGH the cable has protected from overcorrect but the design was faulty and I vaporized a #8 cable (3mm diameter copper conductor) I

I saw that 25x25 tube and though "use it as conduit", "use it as housing for electronics", "use it as a heat sink", "EMI shielding if you ground it." "I wonder of batteries will fit inside?"

I thing the most valuable space in the robot might is the inside of the 25mm square tubes

Robots like these and to fall and take bubbles down stairs or worse the limbs get into self-collisions and rip wires from each other. At least until the motional planner is fully debugged.

I know first hand that LiPo battery fires can't be put out, you just have to wait.

I think a good way to design a motor driver is to look at what controls the driver. I think anyone building a walking robot is going to be using ROS/MoveIt or ROS/TOWR so you'd want to run ROS Serial and a joint controller node on the driver. It would save a ton of work to build the controller on a CPU platform that can run ROS Serial. Not looking upward at the higher level controller might mean you later have to introduce a layer between. A chain of controller adapter PCBs is ugly.

STM makes the STSPIN32F0 with builtin MOSFET drivers the chip is designed for robotics and BLDC motors.

The higher level controller likely a "Joint Trajectory Action Controller" attempt to place joints in space at a given time and velocity within the limits of the hardware. This is the controller this driver will need to interface with. best to make it seamless.

All that said. I'm pretty sure I'll be using a stepper motor at fist. Steppers are easy to control.

> I think anyone building a walking robot is going to be using ROS/MoveIt or ROS/TOWR so you'd want to run ROS Serial and a joint controller node on the driver.

If you look at the walking robot projects (https://hackaday.io/list/29475-walkers), you will notice that very few of them use ROS in any way.

But they also lack any interesting behavior other than walking. What's the point of that? I would think the reason you use legs rather then wheels is because wheels can't work for you application. But so many of these robot have no application.

As a minimum, I'd want antonymous navigation and route planning that gets from point A to point B without attempting to walk through solid objects, replannrng aroubd obstacles.

We see this a lot with hobby robots, nice mechanics with no software

Some of them have pretty interesting behaviors. Also, lack of application is not an exclusive feature of ROS-less robots.

For "antonymous" navigation you need sensors that cost two orders of magnitude more than the whole budgets of those projects. But they usually do obstacle avoidance, so they don't walk into things.

No software is often better than crappy and bloated software. At least you get to learn how it actually is done.

Albertson.chris - can you tell me about the joint controller have you have made?

The PSOC4 controller can be configured to support the following communication protocols PWM, I2C, SPI, UART, RS485, USB, CAN, Step/Dir and LIN. I like CAN the best, as the packet handling is supported in hardware and it has a higher immunity to noisy environments. The CPU is running at 90% idle, so i'm sure adding some sort of Trajectory planning should be possible.

The current big quad I'm designing requires interaction between the joints as the two actuators are joined as one parallel linked series elastic actuators. Two controllers, two gearboxes and one series elastic actuator. This will most likely require a centralized controller.

The CPU in the STSPIN32F0 is not a "high end" controller. 4KB of RAM is not much for a Robot controller.

I think a robot controller for a robot that has as many degrees of freedom is a quadruped is going to be hierarchical. Every group of 6 MOSFETS controls one motor has one CPU. The cPU only has to run a position and velocity feedback loop and monitor temperature. I would bolt the mosfets to the 25x25 mm tube as a heat sink. These controllers could live inside the structurel tubes and all connect to a bus and DC power. 4K is easy enough to run a couple loops and control one motor if not get a bigger uP.

The next layer of control like does coordinated movement. It receives as input a series of vectors. The vector has a target position and velocity for every joint and also a time tag for when those positions are to be realized. It then sends commends to all the motor controllers to update their set points such that every point gets to it's target at the same time.

The next level above os motion planning. It's output is the vector of joint targets

Above that is the SLAM and navigation. The robot needs to know where it is and how to get to where it needs to be and hw to rout arub fixed and moving obstacles. This means a LIDAR, Vision, IMU, Kalman filters and so on. This is where ROS is best used. One person could never write a modern SLAM and sensor integration suite in one lifetime.

The level above is what decides the where it needs to be part which is likely based on a high-level command give by the owner of the robot who just said "go downstairs and fetch me a beer"

Using the "fetch me a beer" scenario is a great place holder. It the design can do that is is general enough. I don't need a beer fetcher but I do want a personal assistant for a blind person. A machine that cn read signs and not bump into walls and communicate by voice.

I've been looking for motors. Hoby King has the one in the you tube video. But then checked industrial brushless motors and found a line of them a StepperOnline.com One of them has a Kv of 111. That means 3X more torque per amp. Same price but physically larger in the axial direction by a lot, but on the other hand I doubt it needs cooling. Likely more weight.

Maybe suitable for an indutrial robot arm that with base fixed to platform

I just read the comment about casting. It is not hard. You can print a mold, pour in the resin then, here is the key: the mold comes apart in two or three sections. The mold parts have flanges that bolt together. and have registration indents for precision alignment. Coat the inside with some kind of mold release and car past wax.

I will have access to CNC mill just as soon as I finish my CNC conversion project. Milling from mild steel is not as hard as it seems

Comercial cscloidic drive this size use grease only the larger ones need a oil bath. I'd stay with white lithium grease

Now to find suitable motor

I have been looking for an actuator for the exact same reasons you were. My goal was an affordable quadruped that could jump off the ground. Yours is great and (I say this in a positive way) there is room for modification which means it could be even better.

I think the electronics can be very much simplified. and I don't know how your position/velocity feedback works yet or anything about the magnetic encoders.

About cooling, yes, the motors likely can run hotter than you are letting them get and remember that heat flows in proportion th the difference in temperature. So hot is not bad. My first try would be putting a fan in the shaft then making the mount out of aluminum and a thermistor some place to measure temperature. I'm going to have to build one of these and study it. Thanks for all the hard work

I need to buy a brushless motor -- Sorry I've not read everything yet, do you a source for the motors? Or a model number i can google.

Any ideas and improvements are always welcome. For the electronics you can get a uC with inbuilt FET driver but then I loose the ability of the PSOC FPGA section (which is very useful). The advantage of the magnetic encoder is you can get full torque at 0RPM at angle angle using FOC. The motors are from Hobbyking Multistar Elite 5008/5010 or from Arris Hobby 5008/5010/5020 or from Foxtech 5010 or T-motor 5008/5012

Really cool project! I'm interested in motor control myself. What resources did you use when helping design the motor control electronics? Specifically related to the PWM, DRV chip, etc.

ODrive and VESC are a good starting point. For the FET Drivers, I like the smarter chips of TI's DRV8xxx family. They offer various control and fault detection options. Gate control can be tricky and these chips handle them easily. The main reason for my custom controller was to have full motor torque at 0RPM.

[this comment has been deleted]

I was comparing the actuator to the DYNAMIXEL PRO line of robot servos. They start about $500. I will update the BOM over the next few weeks.

Nice work! I’m very interested in your project. I’ve tried to make cycloids in the past. My sixi robot arm needs a min holding torque of 20Nm at the base. What kind of play are you getting? (How’s the repeatable accuracy?)

The backlash is quite small but that is all relative. It is good for a quad, not sure about a robot arm. It depends on the tolerances of the 3D printed Cycloidal gear. The joint position sensor is 14bits but getting the magnetic sensor and diametric magnet concentric will effect the accuracy. I have seen people have a calibration table for the magnetic sensor, so maybe the usable accuracy is only 12bits.

It reminds me of transformers and other robots that have rotating discs in the joints, and you made it real, waaaah !!

Khudos, I really hope you were one of the individuals in the top 20 who got the $1000 prize, this concept is really cool and I love it!! It could be used in any joint in robotics.

Thanks Josh. I was one of the 20 finalists. I think that the electronic part of the actuator is not the easiest for makers to implement into their designs right now so I might improve it a bit. The PSOC4 is not an easy chip to learn. Maybe something Arduino compatible.

I hope the prize encourages you to keep developing it, I normally use high torque servos on my robots but I would like something better and purpose built like this, if there is any way I can help .... even testing some setups I’m happy to be involved

Can only second my previous comments. The level of work and detail on this project is incredible. I am very excited to see the outcome!

Become a member to follow this project and never miss any updates

Anthrobotics

Anthrobotics

Scott Duckworth

Scott Duckworth

matop

matop

Christopher Xu

Christopher Xu

I have an updated design. The bolts helped, but the actuator still binds when the assembly is compressed axially. This new version includes aluminum spacers. Switch back to version 50 for a better view.

https://a360.co/2yxWgQO

I built a prototype of the base design. Clearances look good, I'll print out a new prototype when the spacer parts come in with PETG.

https://i.imgur.com/kwM9mN0.jpg

It looks like you're planning on using these at 12v. Would it be reasonable to assume that it should approach 20Nm of force at 24v?

I've been looking at your spring compliance setup. I don't see a 3rd sensor for spring deflection. I think... that if you're measuring shaft count / position and joint position after the spring you should be able to derive force and imitate compliance. I have an idea or two on how to integrate that into the actuator.

And after futzing about a bit with the stm32f103, and then moving to the stm32f302 after realizing that the 103 makes you choose between CAN and USB, it dawned on me that there is no point. The PSOC 4 is a good fit for this application and seems to work well. PCB design isn't my strong suit, but I'm working to convert your design to a circular board integrating an AS5147 in the center, and using one of your carrier boards underneath for the motor shaft. This minimizes the SPI cable length, and puts the electronics right on the actuator.

Speaking of which, where are you guys finding the AS5147/AS5047? Mouser and Digikey are out.