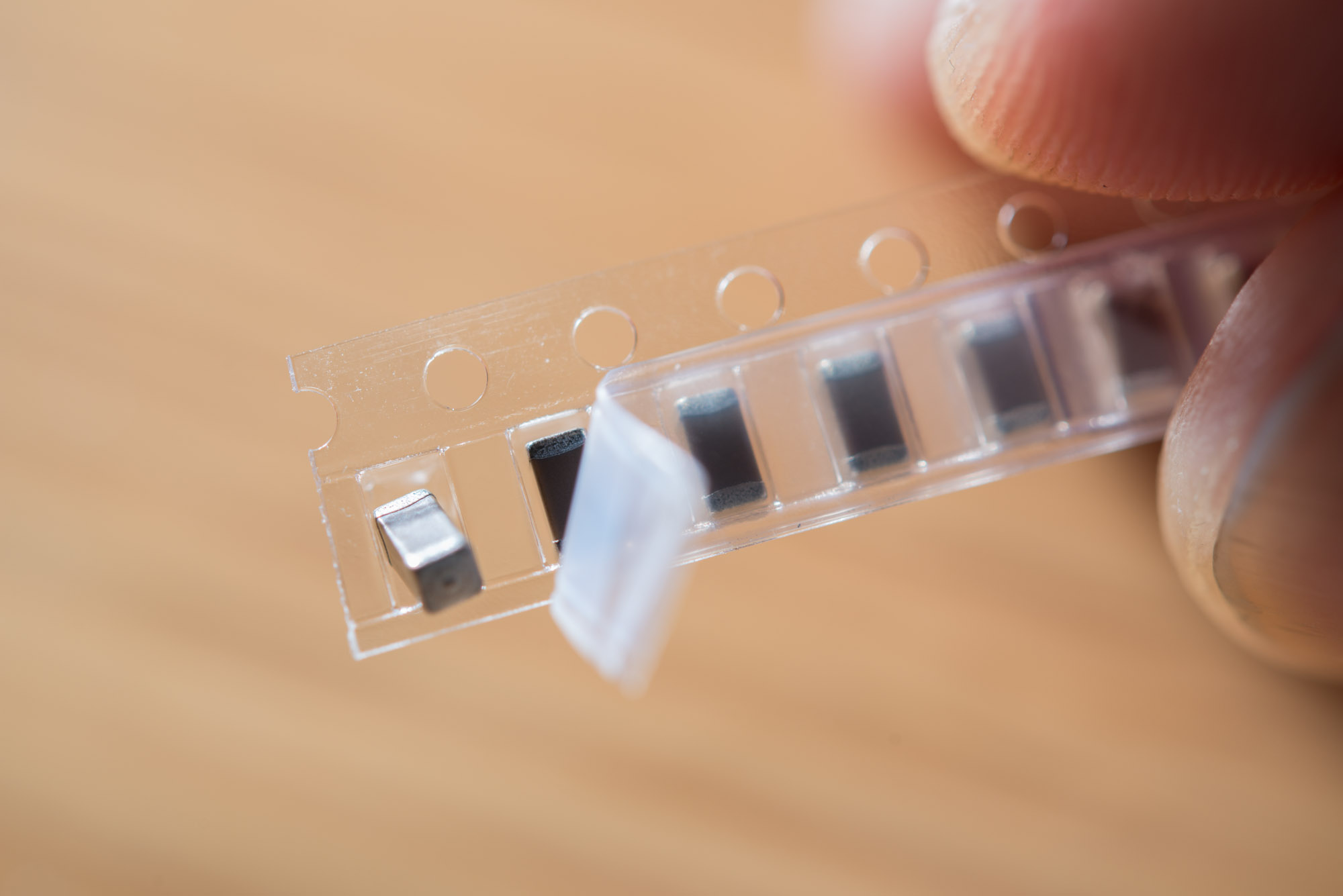

Many SMD parts are provided by their manufacturers on an embossed plastic or paper tape. A thin, transparent cover tape is placed on top of the carrier tape to avoid the components from falling out. The carrier tape has a fixed spacing hole pattern on one side (or both, if the tape is sufficiently wide). Normally, a sprocket wheel meshes with these holes and is spun to advance the tape.

SMD capacitors in tape & reel packaging by Filip Wahlberg. Licensed under the Creative Commons Attribution-Share Alike 4.0 International license.

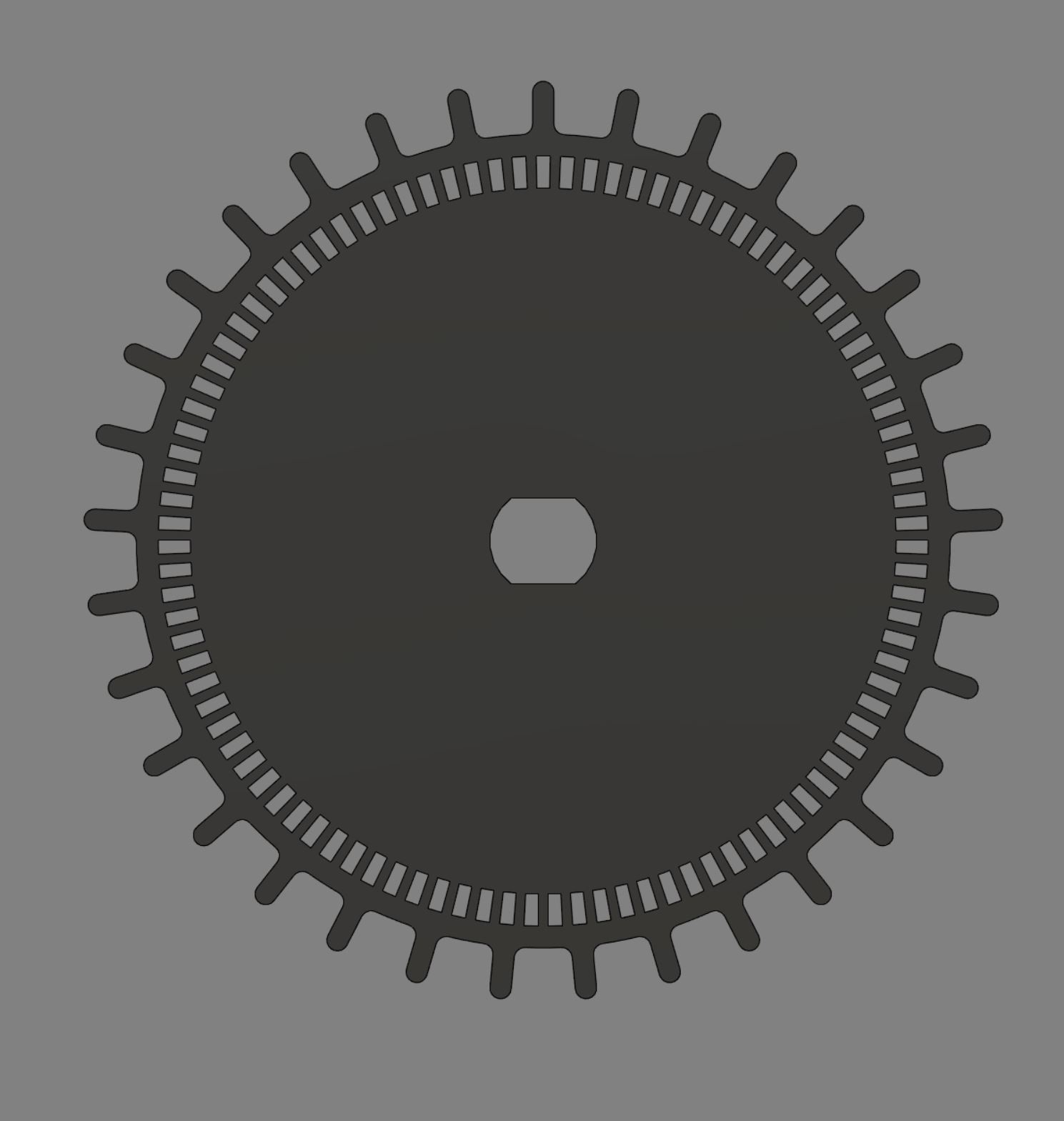

The purpose of an automatic tape feeder is to move a new component to a known and fixed location each time the pick and place machine needs to place the part in question on the PCB. This feeder design uses a sprocket with a DC motor to accomplish this.

Some existing feeder designs use a small gearmotor and a worm gear to reduce the overall thickness of the feeder. I opted to use a not so short gearmotor that doesn't require extra mechanical parts, with a hollow, internally threaded output shaft to greatly simplify the mounting of the sprocket. The same motor is going to be used to peel off the cover tape by winding it up in a small reel.

The angular position of the sprocket needs to be set accurately. A quadrature encoder will be needed to read a pattern in the sprocket wheel so a microcontroller gets position feedback for the closed loop control of the sprocket. A pair of tiny reflective reflective sensor will be used to create the quadrature signal.

ottoragam

ottoragam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.