Ive been working on this project for many months now and there is still much to do but the end is in sight!

In this post I thought it would be interesting to reflect how this project got here by sharing a summarized timeline of development milestones. Often when such a thing is done over time the details on the process are lost, but fortunately I have kept great notes in my google drive!

***Timeline of Design Decisions Chronically starting Jan 2018.***

*Idea Phase- My nagging interest to build 'a robot that builds other things'. Idea for hobby servo based drawing robot sparked by Makerblock's work on Thingiverse.

*Problem Statement- 'Design a profitable robotics kit that encourages kids to persue STEM interests.' Per that goal, the kit should be:

>Replicatable & Affordable- So others can copy this work.

>Unique: To be inspiring.

>Hands-on: Is critical to the learning process

>Expandable: Customization increases user engagement

>Open source: Because I am basing some work on open source SW & electronics and I am respecting their license, and can benefit from help by others,and giving things away for free facilitates advertising.

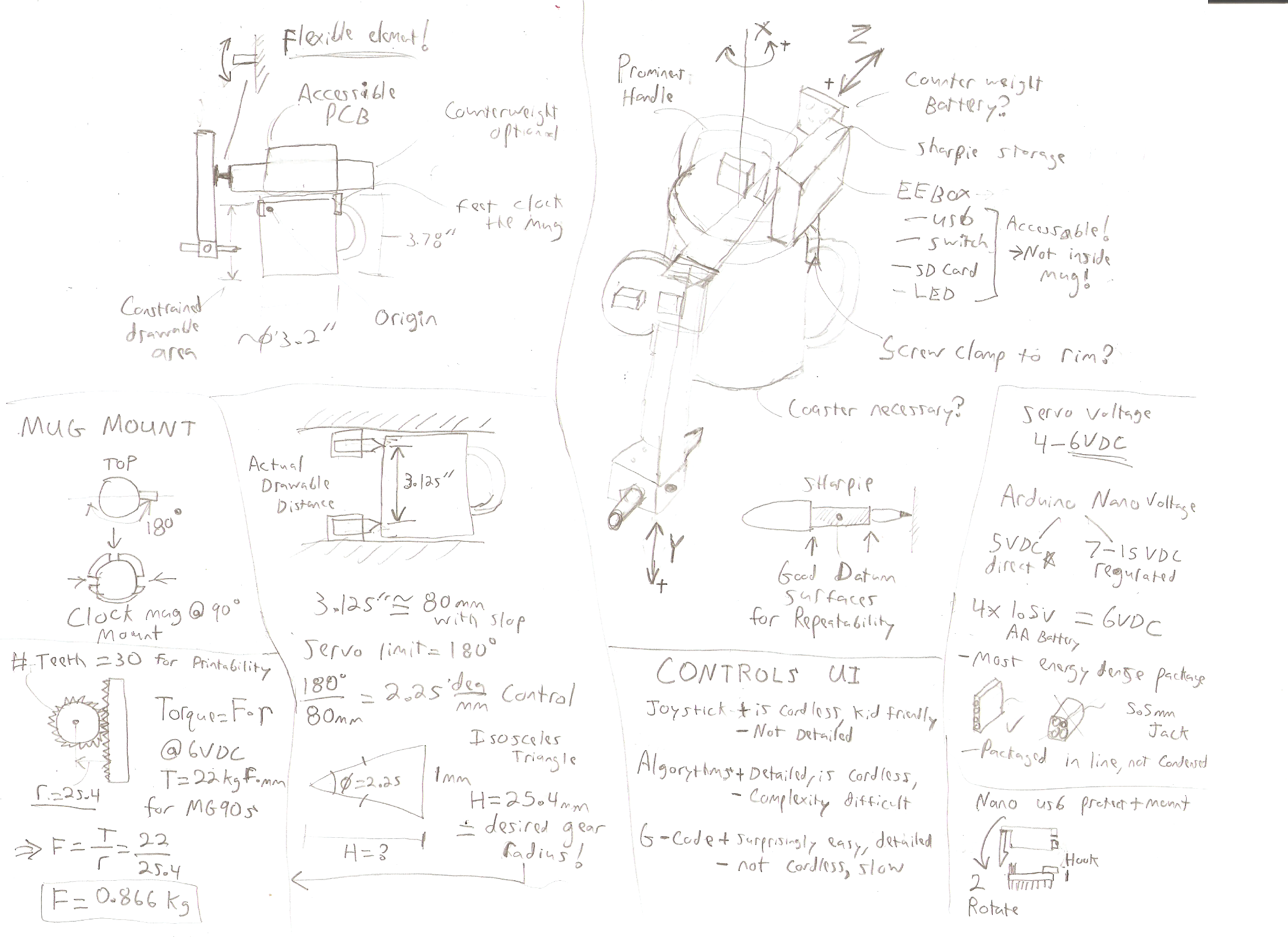

Concept drawings: (Originals done on scraps & on different mediums over time. This image is many design considerations condensed nicely.

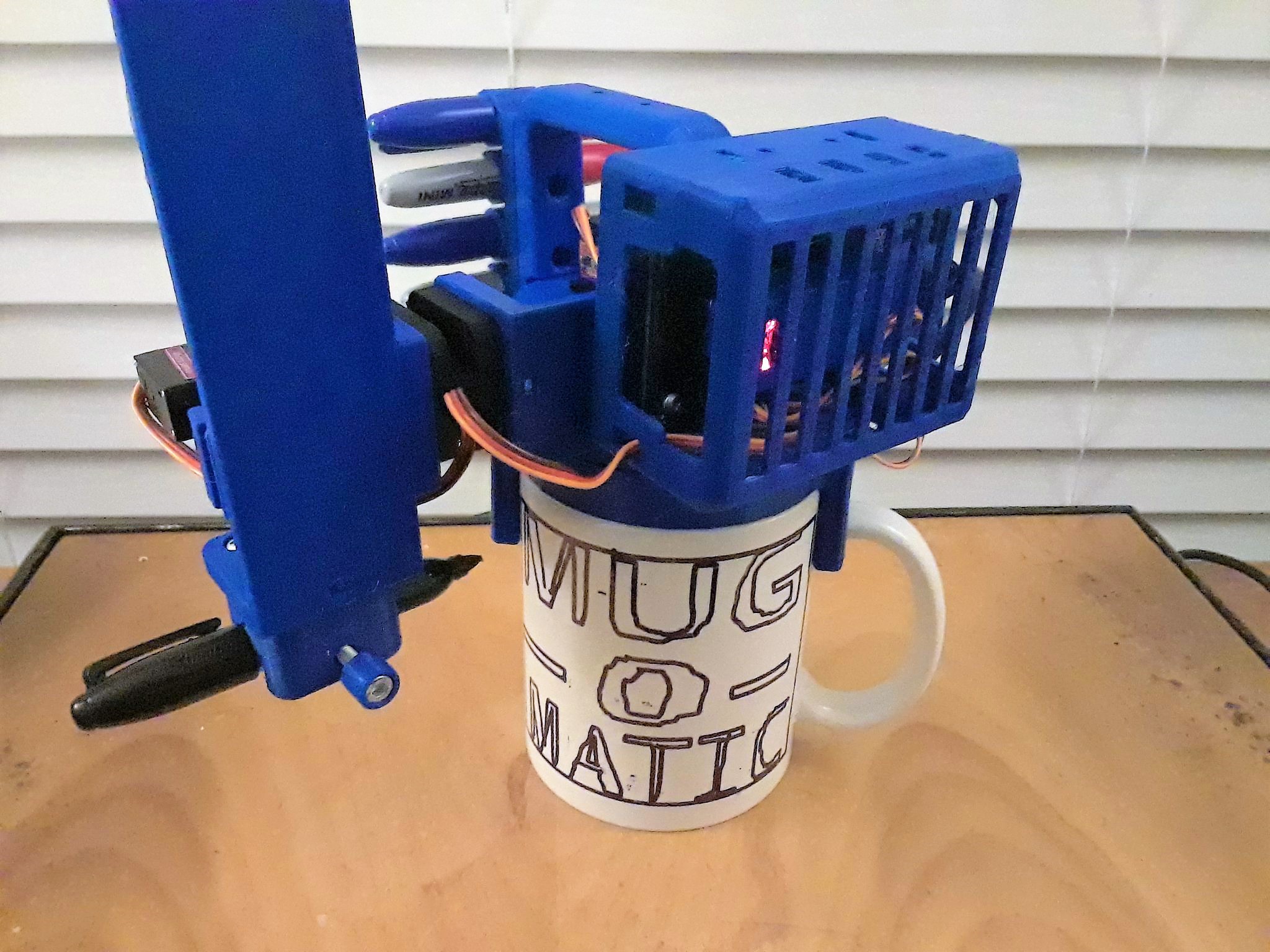

*Decide on the name "Mug-O-Matic" because its fun :) Stuck with it!

*Research for existing projects similar to this to see if I'm reinventing the wheel. Most useful finds were inspirational but nothing else out there does what I want to do.

*Begin design work. Find a ubiquitous coffee mug. Take measurements to determine necessary drawable extents for actuator (80mm). Spec & order most likely hardware to be used.

*Utilize hardware & model elements from my SimpleSumo Robot project to get started quickly.

*Make high level design architecture decisions and set them in stone:

>Toy to use sharpies (mini's specifically.)

>Mug to be oriented upright with robot sitting on top. I considered setting the mug on top of the bot to segregate the degrees of motion and improve mechanical stability during drawing. BUT the overhanging crane arm is distinctive and looks WAY cooler in action which matters more for a toy!

>Arduino & batteries cannot sit inside of mug. Because there is no space, because you need to be able to access the USB cable to the computer, and because it would enable you to dunk the electronics if you weren't careful!

*Research for existing linear actuators. Come up short & start my design from scratch.

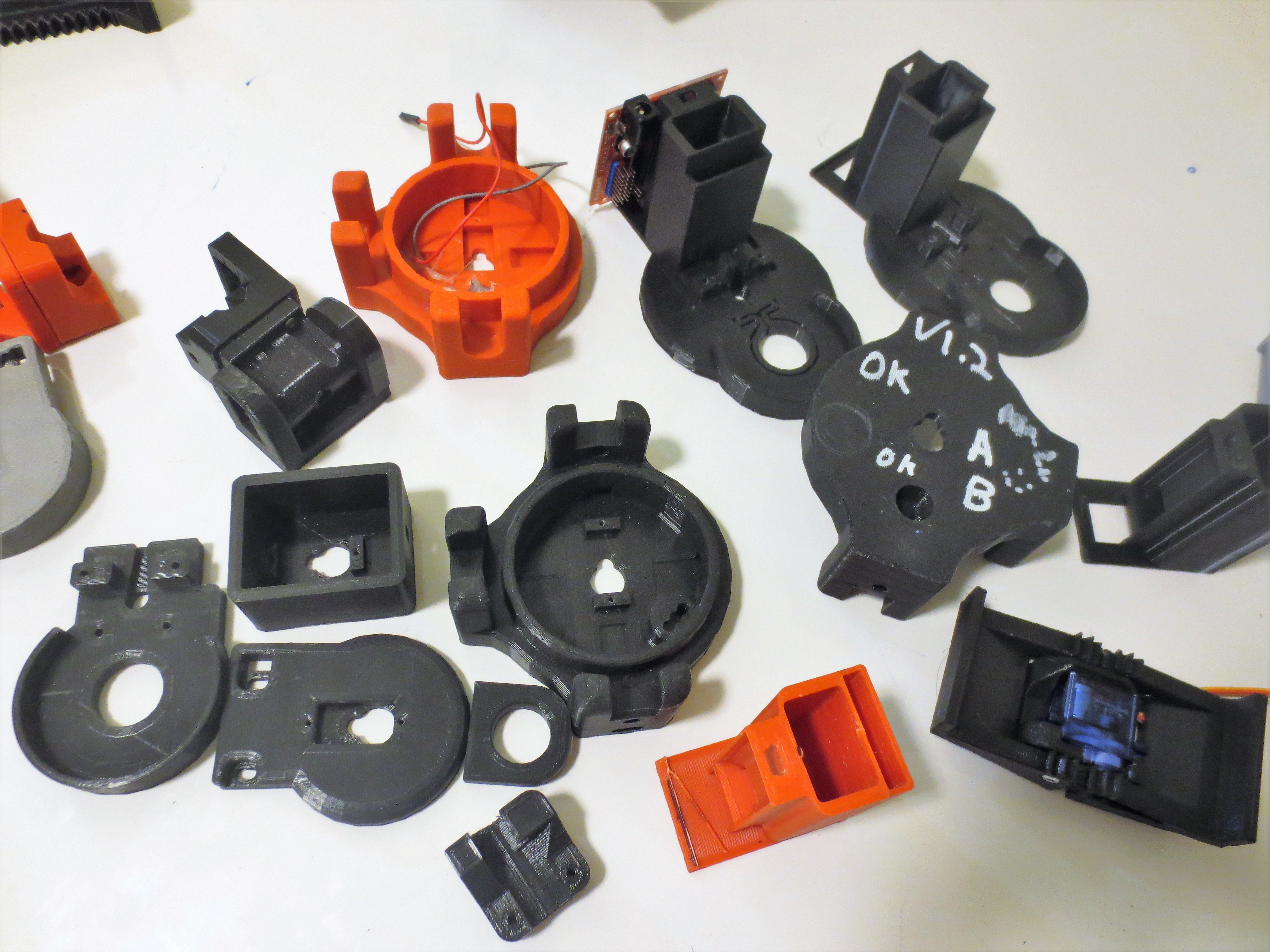

*Prototype assy #1. Very rough. The servos did not have enough power to move the actuator. Assembly freezes up. Asymmetrical parts unsightly. Focused on improving mechanics of the printed parts. (I threw out a lot of prototypes, this is what I had left!)

*Discover that the common arduino nano breakout pcb I was using limited the current that could flow to the servos. Begin searching for other options.

*Realize that modularity would save me effort because the Mug-O-Matic uses 2 linear actuators.

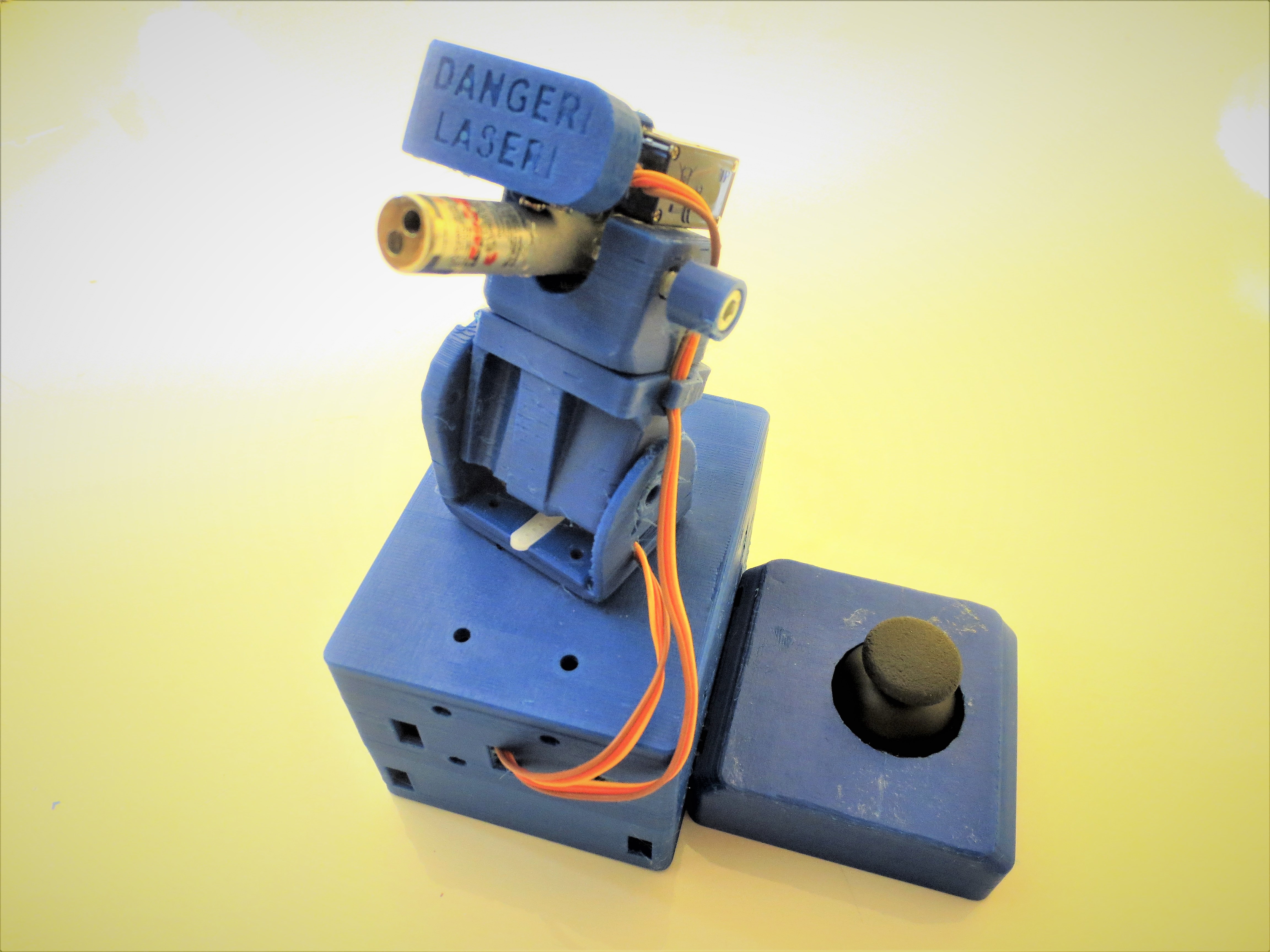

*Realize that modularity would enable a whole bunch of other cool creations. Begin the great distraction of creating the rest of the Tiny_CNC_Collection.

*Repeatedly iterate individual parts to test fit,form, function, printability, etc.

*Thought of the layout for the Post-It-Plotter.

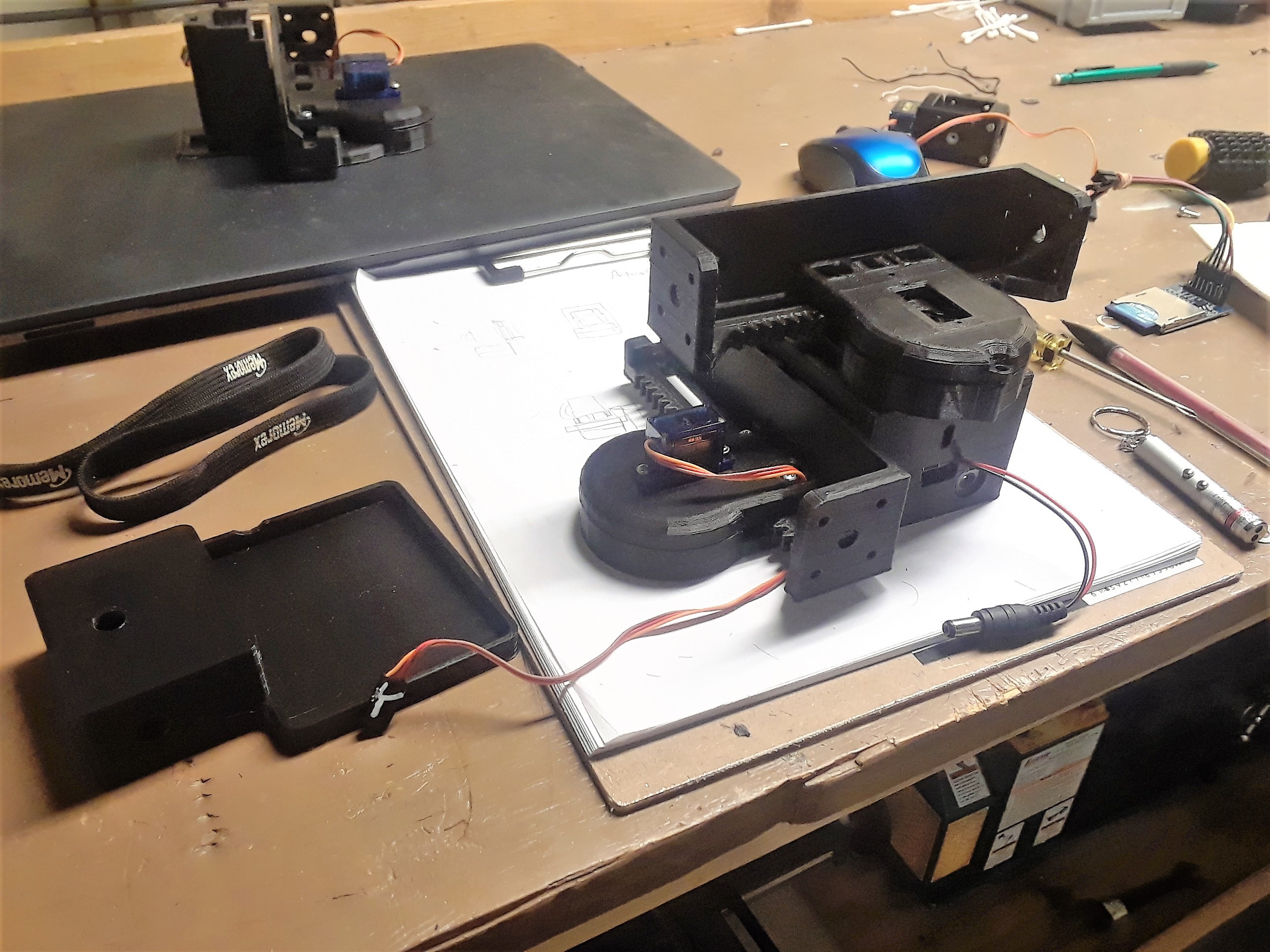

*Prototype assy #2: Getting better. But still had a hard time drawing vertical lines. Realized that I needed to add a flexible element to free the vertical axis from dependence on high 'pen to mug' accuracy to relieve excessive load.

*(You can see the arduino layout is much different than what I ended up with!)

*Lots more repeated iterations of individual parts and sub assemblies. All 3d models custom designed. Enjoyed plaing with gripper & different actuator designs & imagining different uses for a tiny CNC.

* Realized need for line segmentation algorithm to prevent momentum caused overshoot issues.

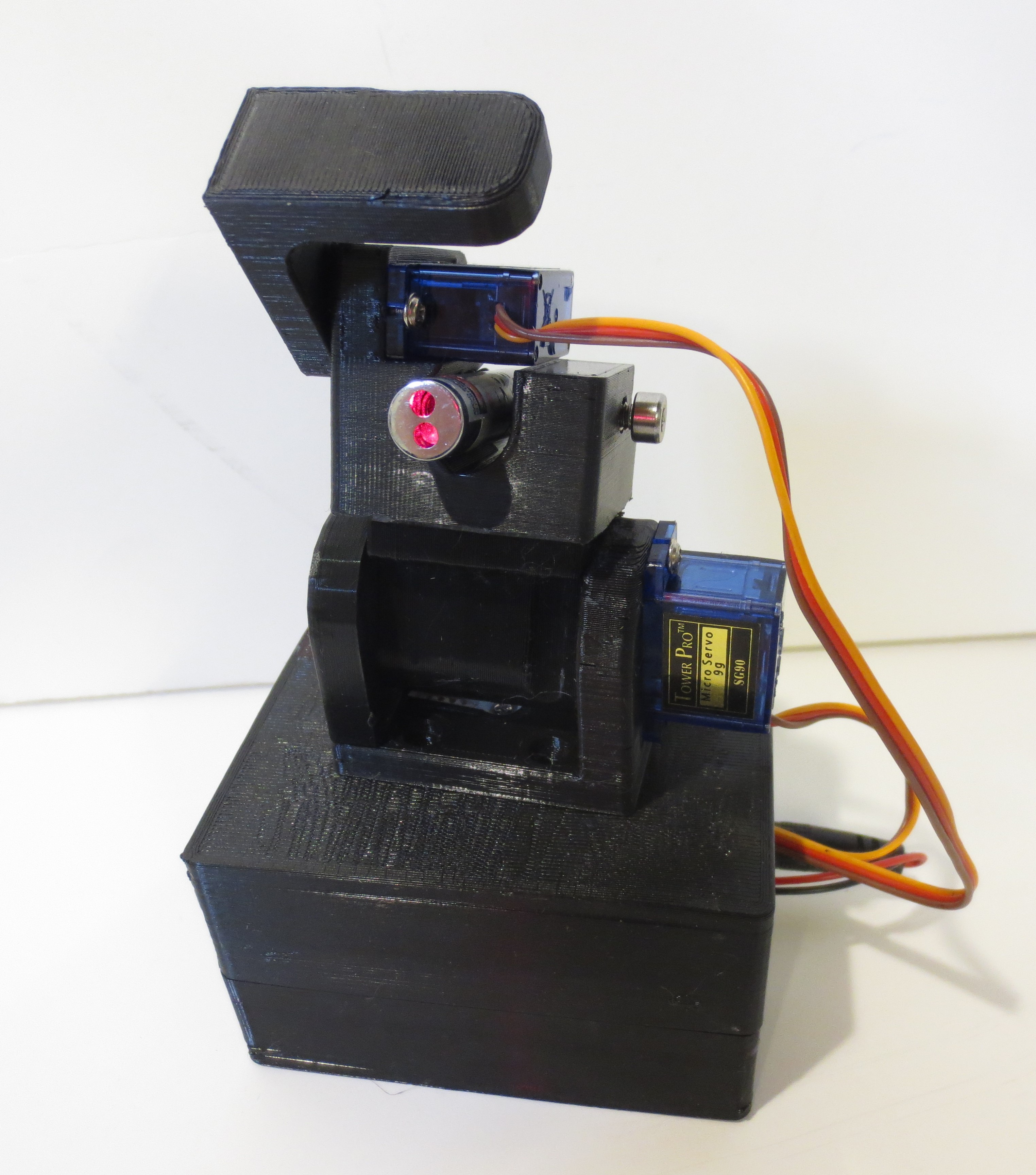

*Determined that MEPED PCB is a great option for this robot.

*Decided to design new PCB based on MEPED PCB. (Also a good excuse to learn KiCad.) Make design adjustments to remove unneeded functions, move things to improve fit, add elements for desired functionality. PCB design quoted, PCA BOM pending.

*User testing- Play with prototypes with middleschool robotics club. Determined ciritcal need to optimize designs + tools for small inexperienced hands and to create more concise & user friendly instructions.

*Complete mechanical BOM. Decide on use of batteries > wall wart for standard device. Have to find a place to mount batteries.

*Still getting distracted designing fun extra modules & assemblies.

Prototype design above. Final Design below.

*Kickstarter tease announced on EngineerDog.com. Trying to determine consumer demand for the Mug-O-Matic. Still not 100% sure if I can pull it all off.

*Decide to pick solid blue PLA+ as the offical material & color scheme. Black was considered because it looks professional, but it is hard to photograph. White was considered because then you can paint it any color you want, but painting is tedious and white lacks personality.

Blue is more playful and more suggestive that this is a toy. All parts being the same color & material helps the logistics of producing them as kits. Parts are designed to work in any material but PLA+ is a good balance of printability, cost, rigidity, and finished appearance.

Similiarly, settling on official layer thickness of 0.2mm balances finish quality & printing speed.

*Prototype assy #X: Completed design optimization + verification. Optimized line segmentation drawing algorithm. :) Realized stall detection impossible. :(

*Lay out & photograph step by step assembly of different robots. Whiteboard style instructions.

*Enabled Gcode functionality! Enabled basic bluetooth functionality! Robot kicks butt!

*Realized the benefits of grease for vertical linear actuator. (A tiny addition with outsize benefits!)

*Confidence in design is skyhigh. Designed Mug-O-Matic Logo in MS Paint in 2 hours late at night + Create Business Cards.

PENDING "TO-DOs" by Oct 22:

*Enable joystick functionality (Nice to have not required.)

*Enable dot matrix functionality- (Nice to have not required.)

*Complete detailed instructional video to go along with images. (Must Have)

*Makerfaire PDX- Toys in lots of Kids Hands! (Must do)

*World makerfaire appearance! (Nice to have.)

*Final Video of FULL DEMO + brief demo of alternative assemblies of Tiny_CNC_Collection . (Must do)

*Shareable files (HaD) + Buildable BOM(Google Docs) (Must Do)

*HackADay Prize Ends Oct 22.

*Kickstarter for Improved PCB's + component volume order. (Still gathering followers so timeline TBD)

Michael Graham

Michael Graham

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.