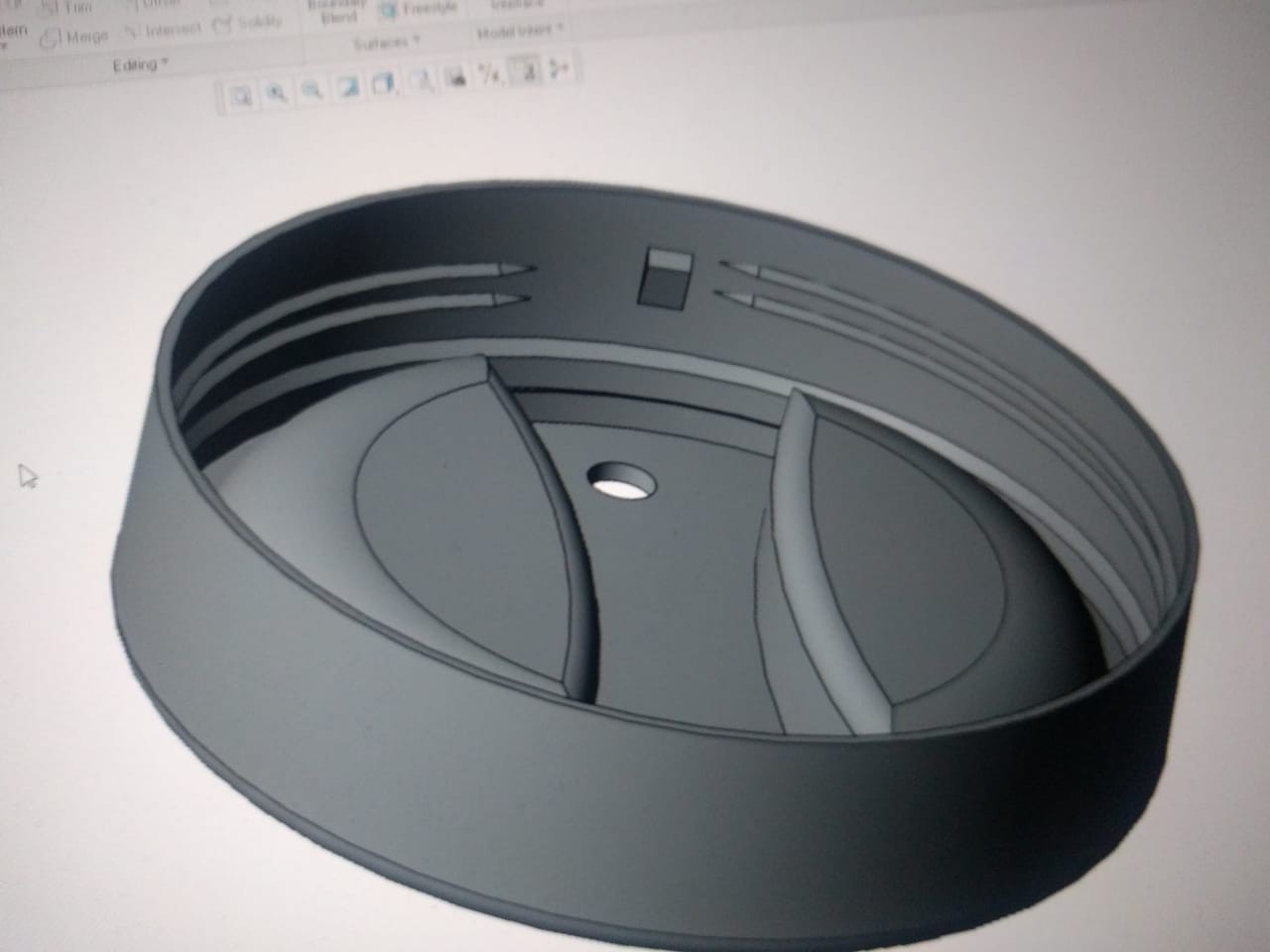

The first iteration will use an existing thermally isolating container with a new 3D printed lid. Almost every part of this project will be housed inside this lid, so that anyone already owning one of these popular thermal containers could add some fancy new functionality to his terere gear.

IoTerere

mechatronics and mate/terere

engineering for Paraguay or anywhere else

And the last one is clunky and sounds like a tractor, but it works. At 5V it needs around 300mA, and there still flows enough water to empty the entire 2,5L in a very short time. For now, this might do:

And the last one is clunky and sounds like a tractor, but it works. At 5V it needs around 300mA, and there still flows enough water to empty the entire 2,5L in a very short time. For now, this might do:

Michael Barton-Sweeney

Michael Barton-Sweeney

Xo Ne Un

Xo Ne Un