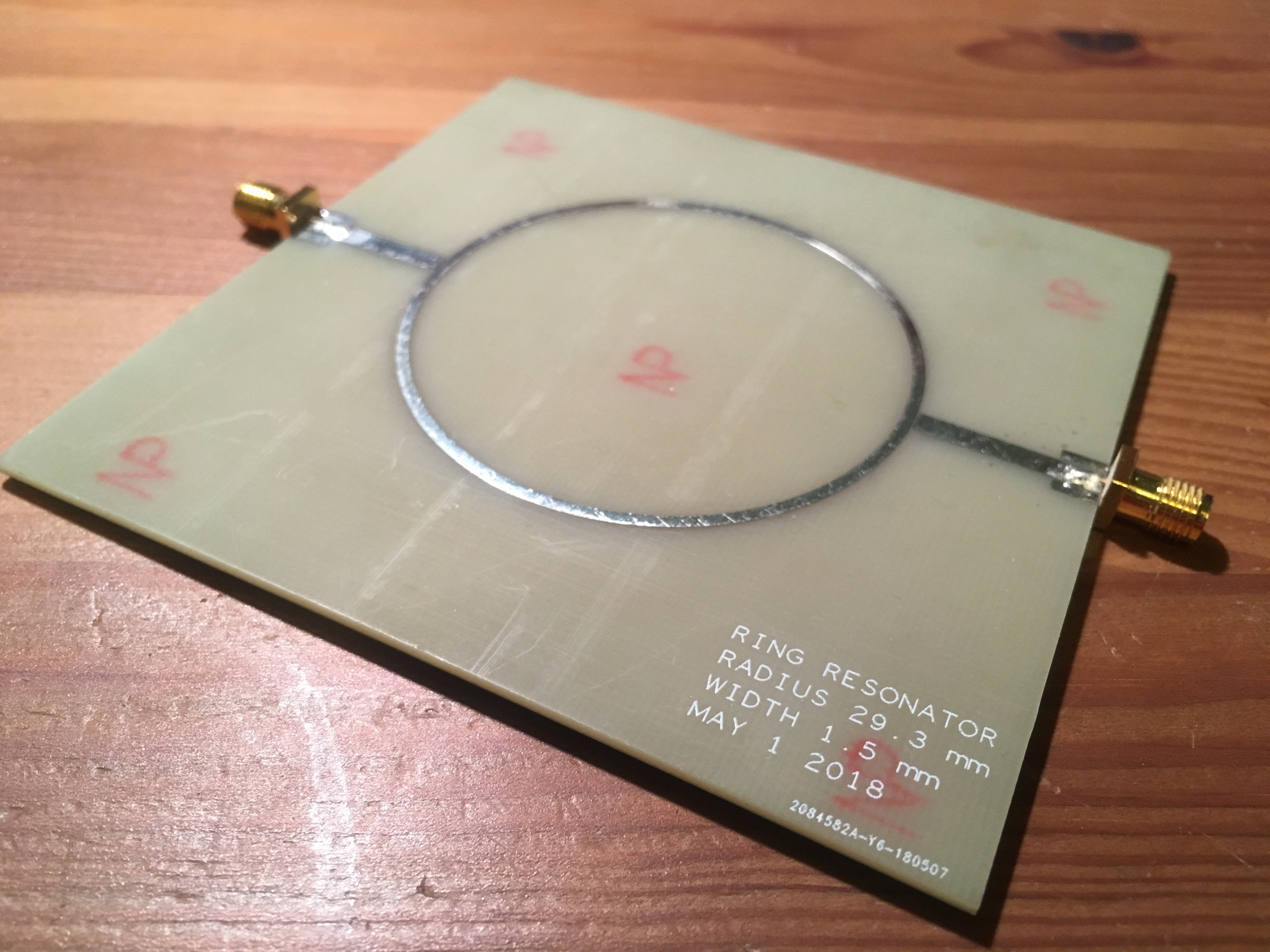

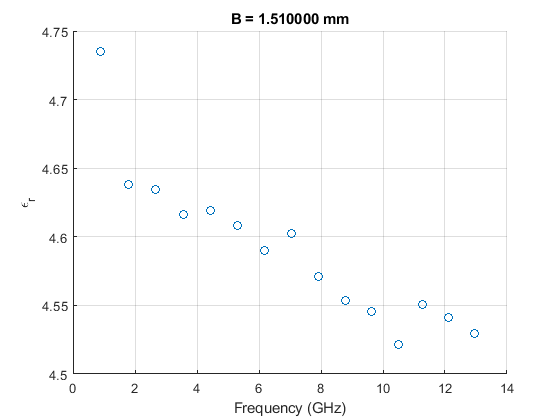

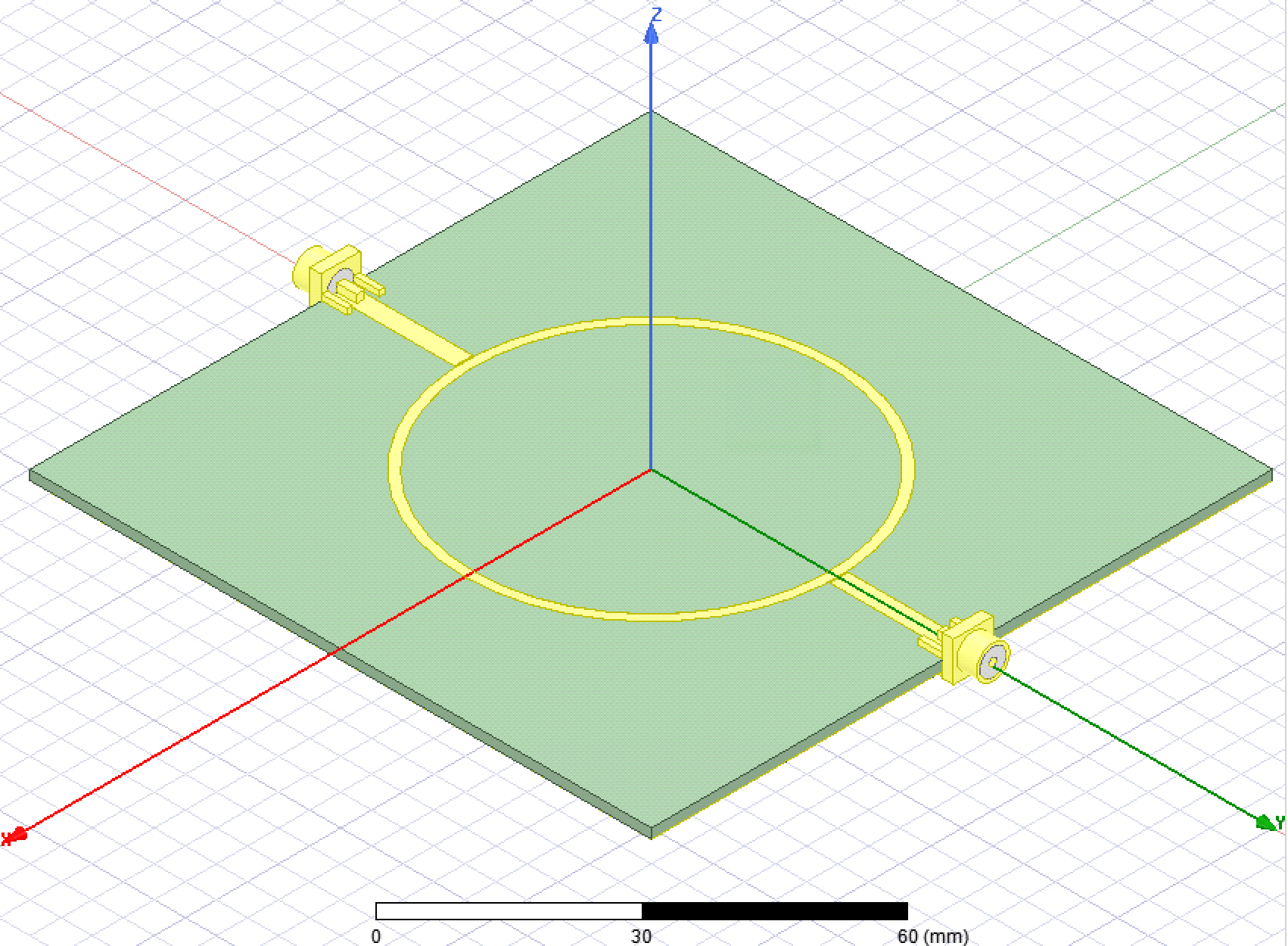

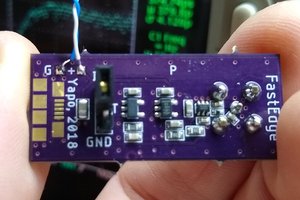

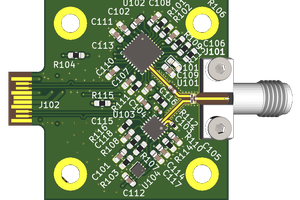

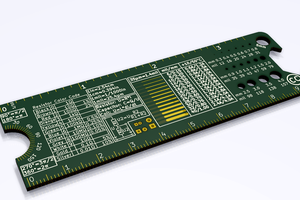

The cheap PCB fabricators don't have any sort of guarantees on impedance, which is part of the reason they are inexpensive. My thought is that if a specific impedance is required, you could fabricate this calibration structure, measure it, and use it to tweak your line width (or other geometry). Then order the PCB form the same supplier quickly and hope that the εᵣ is still the same. Or, you can fabricate it along with your PCB just out of curiosity as a way to check the εᵣ.

Measuring the Effective Permittivity of PCBs

Find out how you can measure the effective permittivity (a.k.a. dielectric constant) of your PCB substrate.

Ted Yapo

Ted Yapo

Michael Schembri

Michael Schembri

MS-BOSS

MS-BOSS

Jan B.

Jan B.

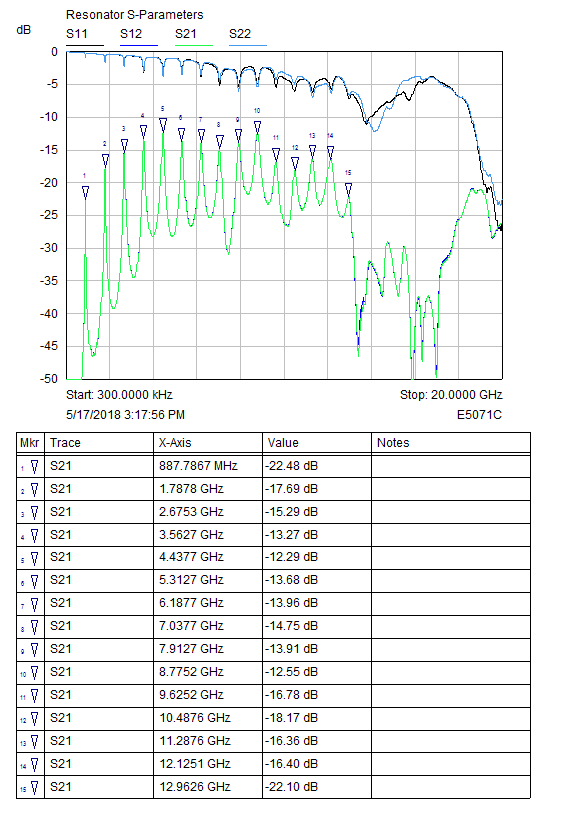

Not to leave anyone hanging on that last comment; I found this paper which is the answer about loss tangent: https://aspocomp.com/wp-content/uploads/2020/03/Microstrip_ring_resonator_method160604.pdf

tl;dr Measure the loaded (Ql = frequency of peak / 3dB BW of peak) and unloaded Q (Ql / (1 - 10^(IL,dB/20))) of the resonator, use this to determine the alpha, and from that convert to Df.