So we decided to have our lawn guy come over and aerate the lawn. Seems like the appropriately suburban thing to do, and the lawn really needs some help. He's got a nice machine, good plug-type deal, and he went over the whole yard good, leaving plenty of dog-turd looking plugs scattered about.

A day or two later, I'm up when the sprinklers come on. I spied an extra fountain of water coming from the lawn, not coming from one of the sprinkler heads. Uh-oh... he must have hit one of the lines.

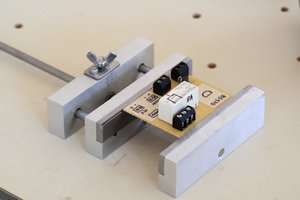

When I dug the area up, it was clear why -- the lines were at most 2" below the surface. There were a couple of half-moon shaped holes in a 1" main, and a slice out of a smaller lateral. No big whoop, just head to Depot and pick up some fittings and repair pipe.

The 1" main was easy peasy. The lateral, though, kicked my butt. I had bought 1/2" because that was the smallest they had, but the tubing was even smaller. Went back to Depot, nothing. Went to Lowe's, nothing. Finally resorted to a supplier to the irrigation trade. Dude didn't want to know about a homeowner problem, and said he'd never seen the stuff before. Not at all helpful with the few questions he deigned to let me ask.

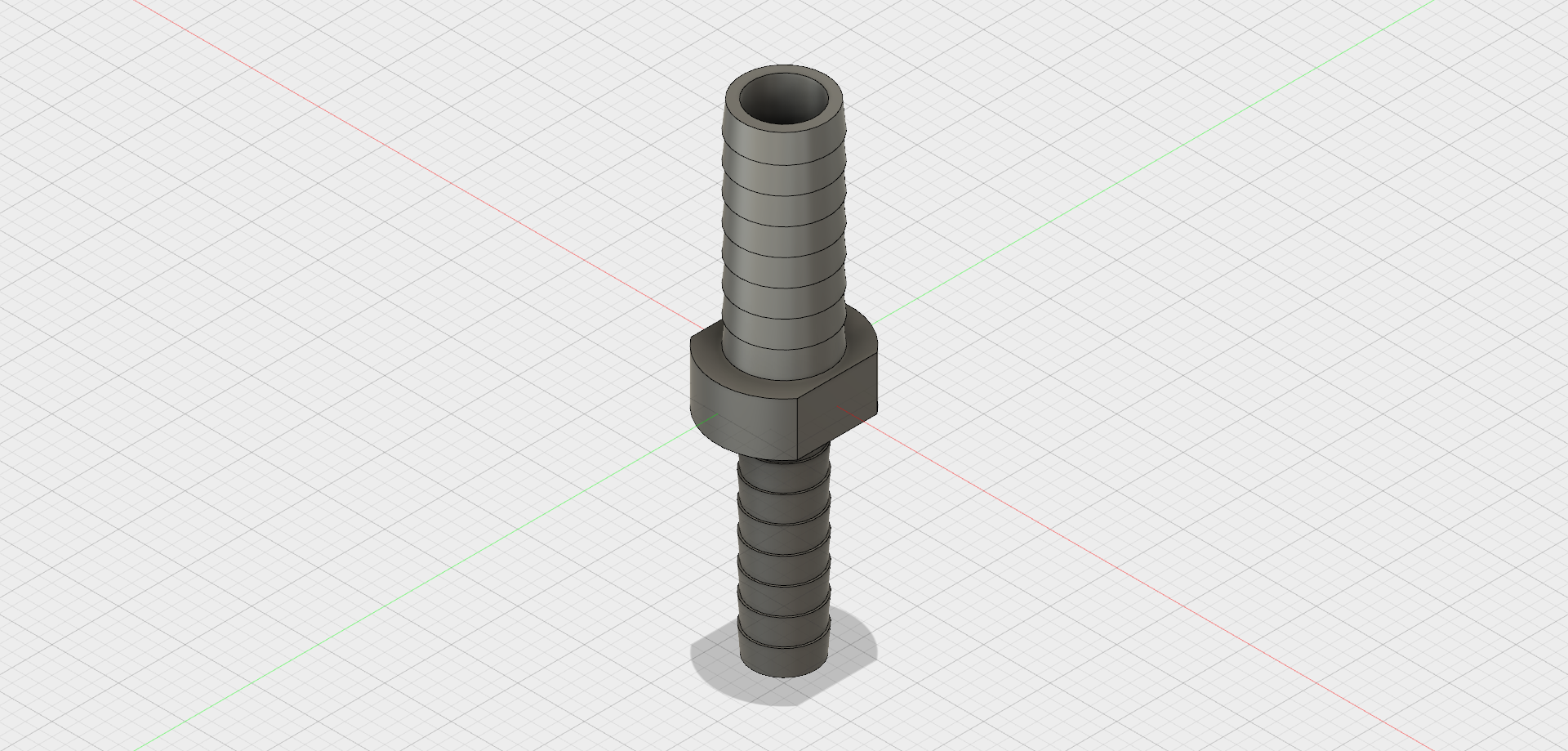

"Oh, well," I chirped. "Guess I'll just have to 3D print my own fittings," I told him. He looked at me like something was crawling out of my ear. Time for me to have the last laugh.

Dan Maloney

Dan Maloney

Jan

Jan

Cedric Anné

Cedric Anné

kristina panos

kristina panos

You've been wait your whole life to flip up your collar and tell someone you'll be 3D printing your own replacement parts. Hahahaha. Good hack Dan!