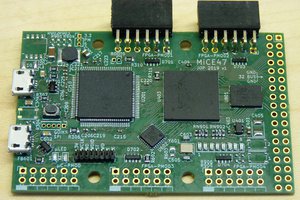

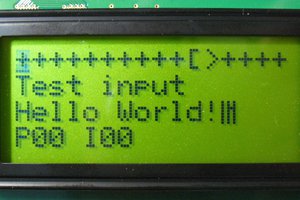

So after purchasing a OBD reader for Japanese based OBD I found that it worked on one out three cars, So infinite wisdom kick in and seeing the USB port on the bottom i proceed to software page of autophix's web site to install the latest firmware, problem is that I installed firmware for the OM126 colour screen unit and not my much needed OM127, worst still is we purchased two units and the other operator did exactly the same. Two units with wrong firmware and OEM wont provide firmware. To make matters worse is the bootloader+firmware is encrypted and so is the external eeprom, so we cant even patch the colour firmware to work on the b/w lcd. So sat with two dead OBD readers we did the usual take it apart.

Logged within the hallow pages of hackaday is our journey to produce a open source firmware for this unit

(Hi Bill H, I still have my C64!!, wish i had a C128)

Ok, enough Brown nosing,

Project so far,

As per the current readme

darkspr1te

darkspr1te

J.C. Nelson

J.C. Nelson

Jeremy Gilbert

Jeremy Gilbert

jaromir.sukuba

jaromir.sukuba