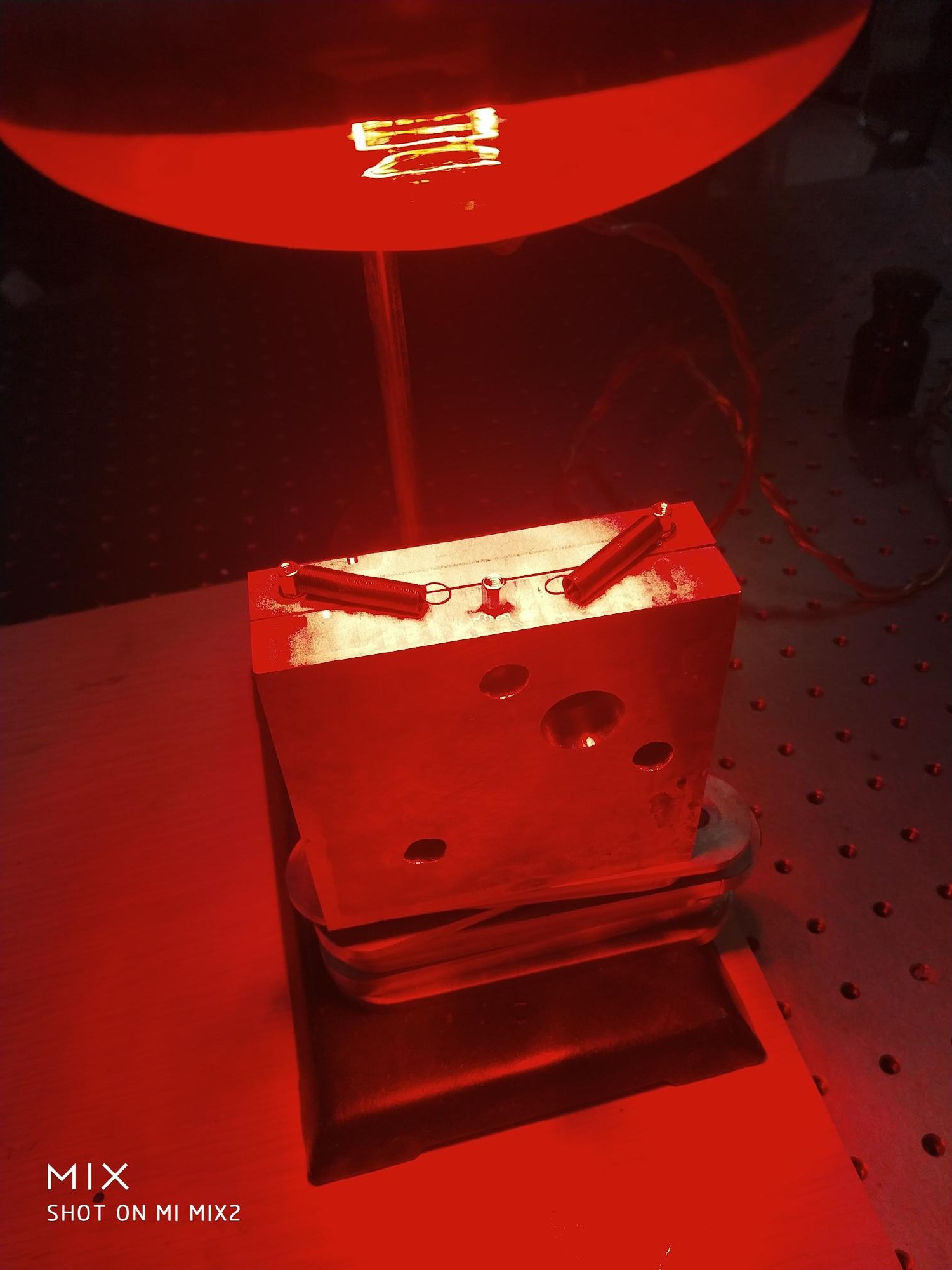

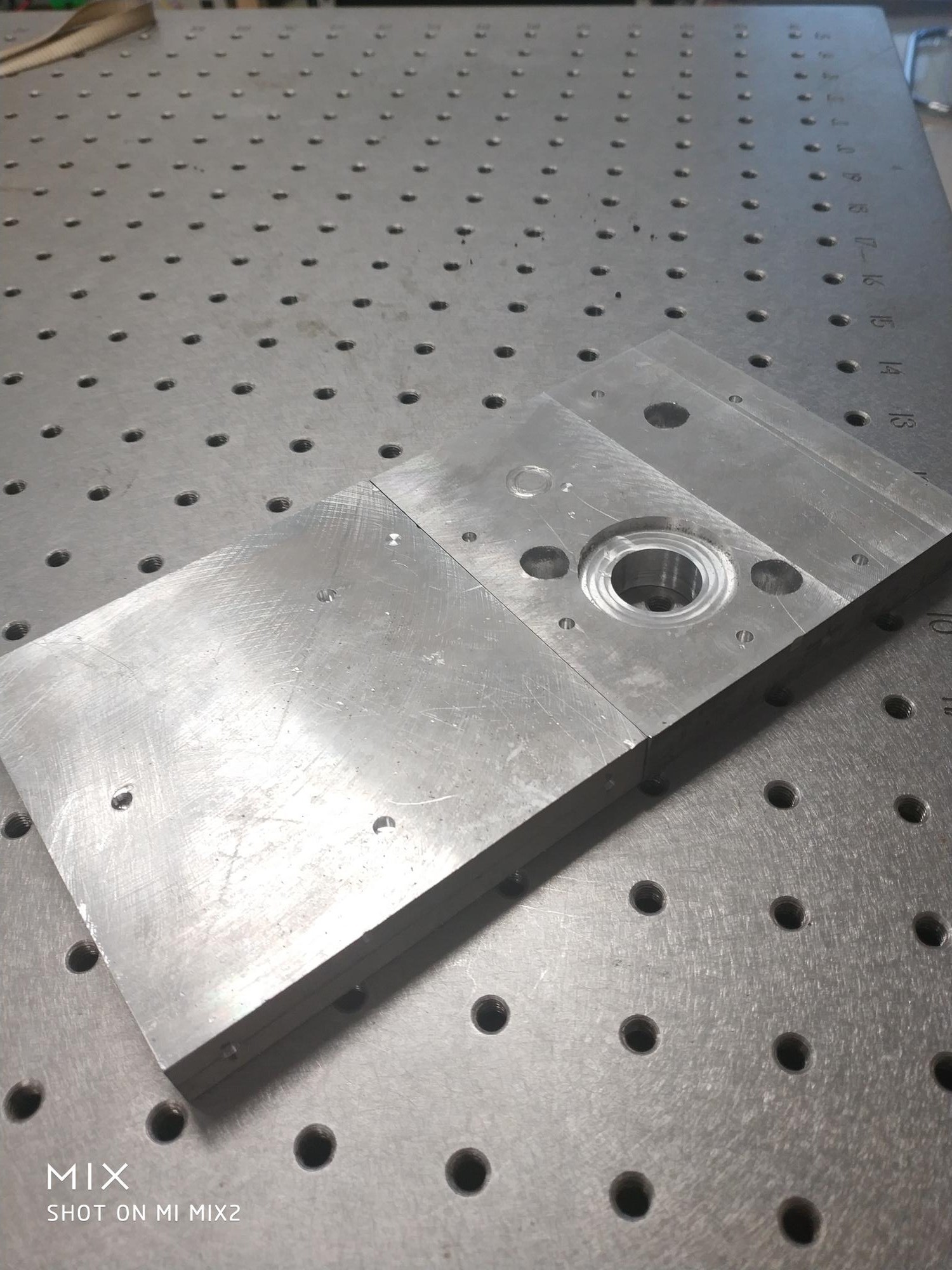

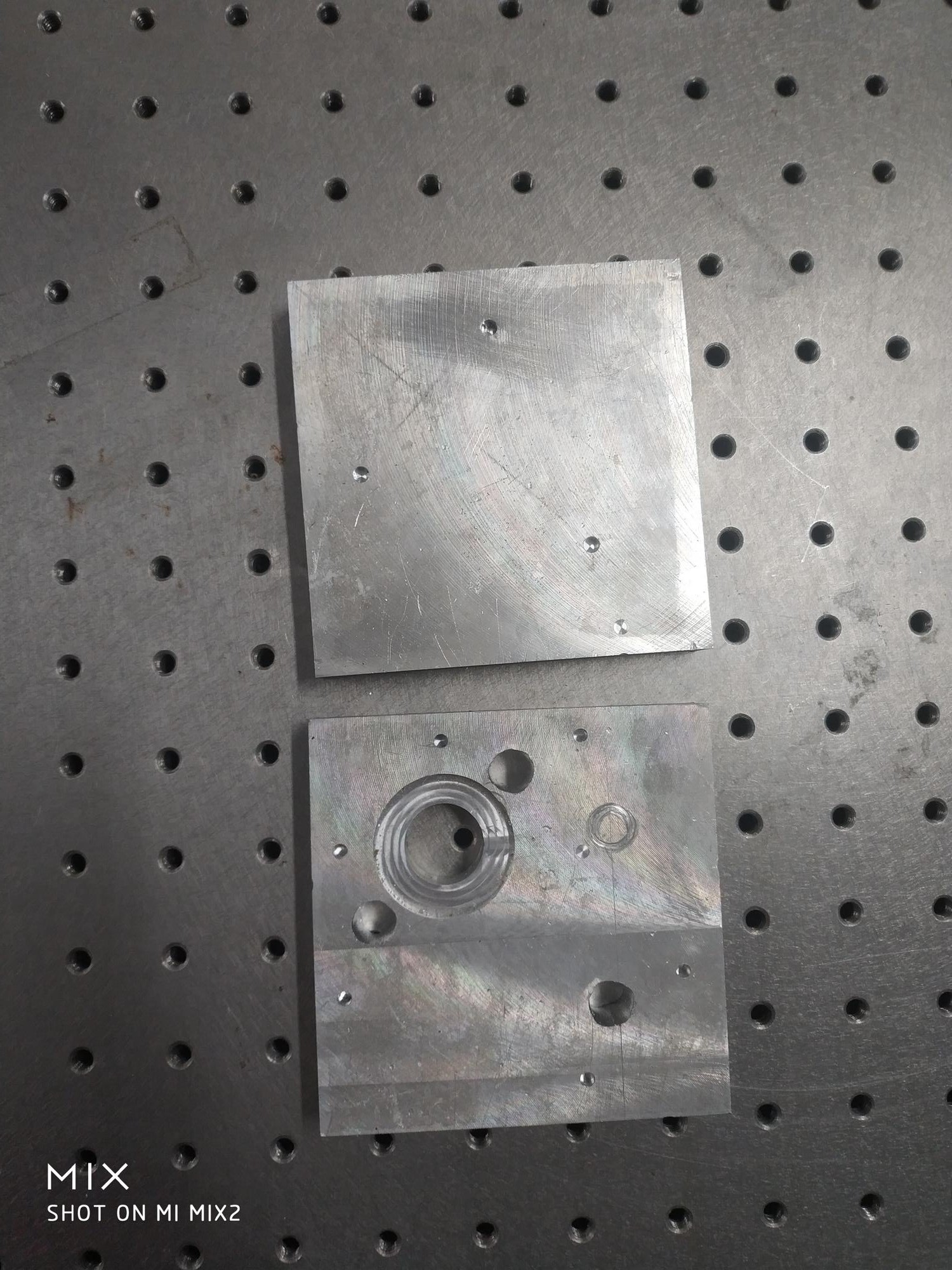

Today I went to the University CNC shop to get the aluminum block processed. Unfortunately, this being a university shop, people who are in charge of the place has a master in Mechanical Engineering, yet, new comer when it comes to CNC stuff. We ended up spend quite a lot of time for just the most basic drilling action.

University shop is mostly concerned with teaching 18 year old that such a thing exist, therefore, they don't have the whole set of tools. For instance, that M3 threaded hole should be the most common thing there is, yet we can't find the drill for that one. So I just decided to drill any kind of hole and then glue stuff to the aluminum using that high temp cured epoxy.

Also, the screw set has a diameter of 9.6mm which has to be exact for this design to work. YET I GOT A HOLE THAT IS 9.4mm!!! Initially, he tried to hammer it in, but that damaged the screw set such that it no longer turns around. So we force it out, and decided to manually increase the hole. USING A FILE!!! MANUALLY!!!

BaiLiping

BaiLiping

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.