So its been a while since my last update but rest assured I am still working on the SolPak!! In the meantime I've been doing a lot of thinking/brainstorming about the pack design. Most of my efforts have been focused on narrowing down how many batteries and in what configuration as well as designing a case to hold it all together. When I'm done designing the physical pack I'll turn my attention back to the balancer/monitoring electronics.

For the most part the mechanical design of the pack hasn't changed much from my proposed diagram. Since the original post I have done bit more research notable reading Jack Rickards EVTV blog posts on the subject of the model 3 battery. I'm going to do my best to emulate the Tesla design as much as possible with DIY parts and fabrication methods. Right now I have a working CAD model in OnShape of the pack.

The design's bas is two 1/8in carbon fiber sheets. One has holes to mount the batteries the other has octagonal cutouts to keep the batters from falling through. The two sheets are sandwiched together to make one top and bottom plate for mounting the batteries. On the outside of these carbon fiber battery mounting plates will be stamped sheetmetal conduits for wiring the batteries together. I'm still working out my wiring configuration and what not so bear with me. These two mounting plats will hold together 72 18650 lithium ion batteries in 4 banks of 18. This pack configuration will require two balancer/monitor boards. The boards will be mounted in a space behind the batteries.

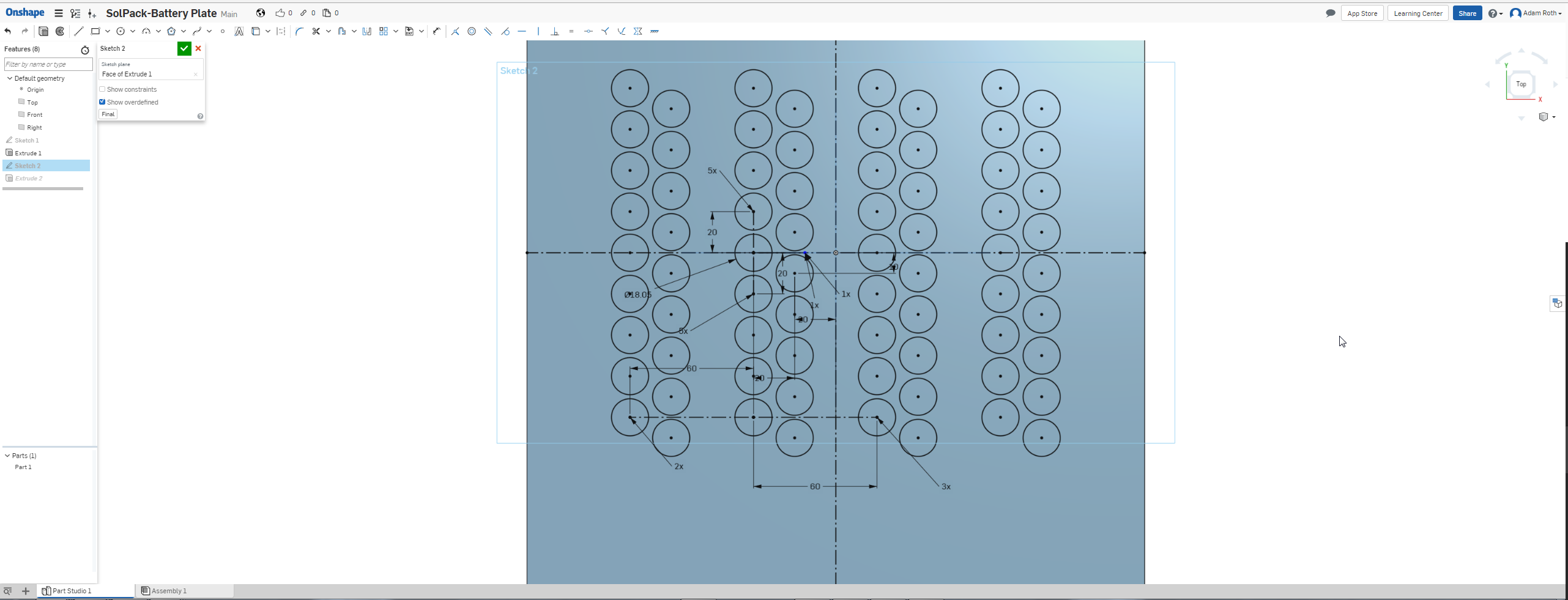

Here is what the CAD is looking like so far:

Defining the Geometry to mount batteries in the plate.

In Progress Assembly of battery pack. 72 battery cells currently mounted in module.

As you can see there is substantial space between the groups of batteries. The space is so that the cooling ribbon/piping can run through, its intended to snake through and around each bank of 18 like the block diagram in the last project log. As for what material I plan to use for the cooling ribbon piping, my plan right now is to make a jig for an arbor press so I can flatten copper pipe and bend indentations in the shape of the battery into it. I'm hoping to use a single long piece of copper pipe and careful metal-work it into shape. I'm still researching the cooling system so the idea is subject to change but the working plan is to sculpt copper pipe with an arbor press like a mad man.

So right now the CAD model is basic but there's more to the design. The carbon fiber sheets will bold onto a 2020 aluminum extrustion frame, or should I say the panels and the frame will sort of support eachother in their construction. I'm going this route since I have lots of the material on hand, its easy to cut and assemble. The box frame will be plated in carbon fiber sheet and look like a big carbon fiber box. I'm hoping to finish a decent amount of the mechanical model and get block diagrams for the electricals together by the end of the weekend.

AVR

AVR

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.