Specs:

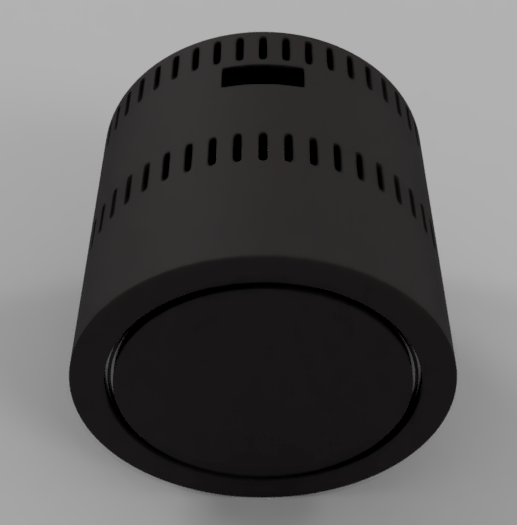

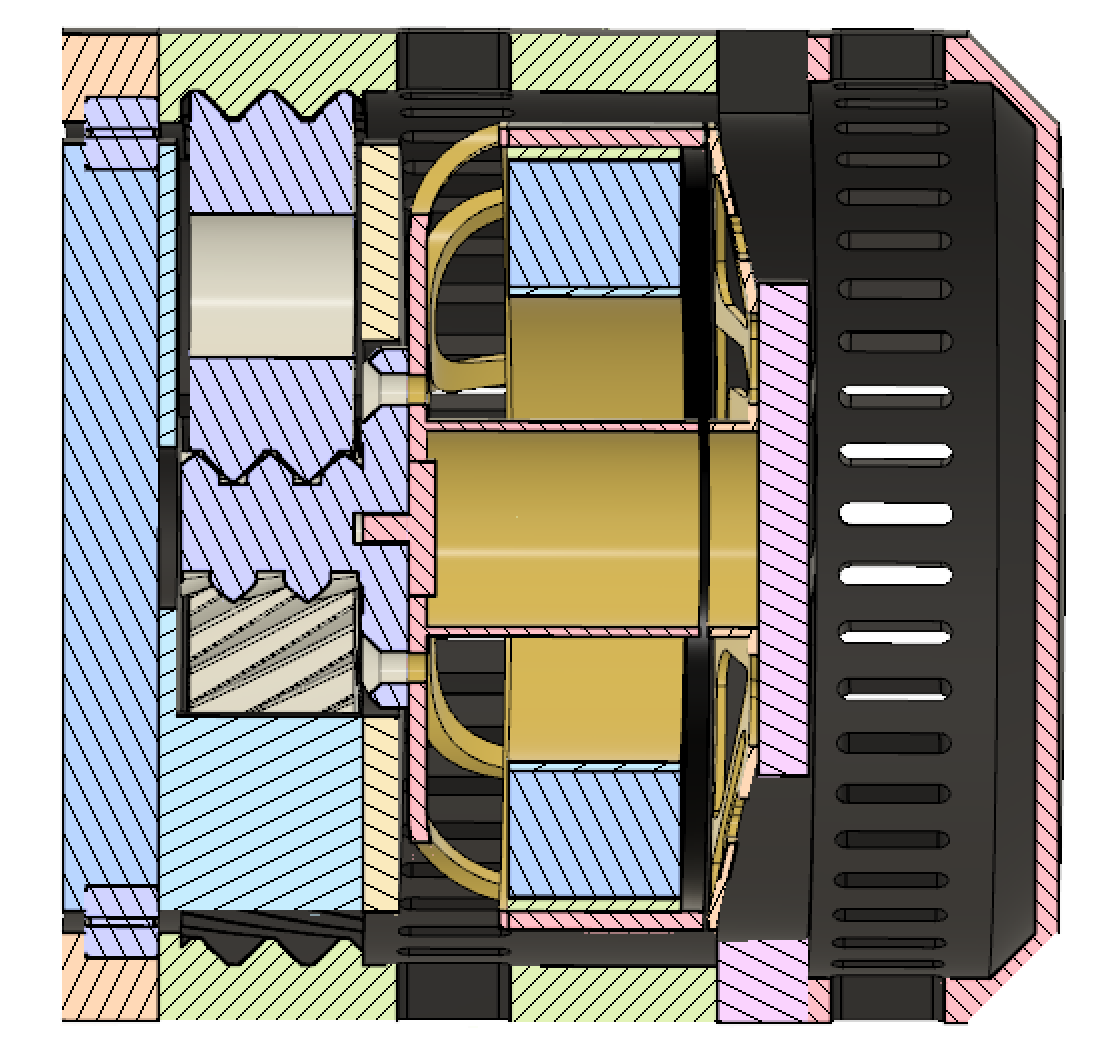

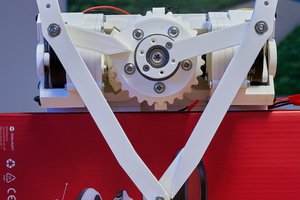

- Peak torque (theoretical): 80 Nm

- Weight: 1150 g

- Gear ratio: 8:1

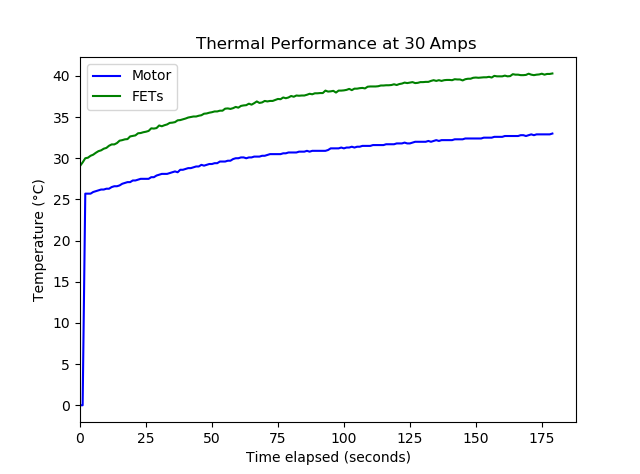

- Cooling: Passively cooled, active air-cooled version in the works

- Cost: ~$150

- License: Creative Commons Attribution - ShareAlike 4.0 International Public License

OpenTorque is being used in the Blackbird bipedal robot. Check that project page for links to the resources and inspirations I used when designing OpenTorque.

Get the latest CAD files and instructions from the GitHub repository:

Ted Huntington

Ted Huntington

Roald Lemmens

Roald Lemmens

Petar Crnjak

Petar Crnjak

Hello Gabrael, your project is really very interesting.

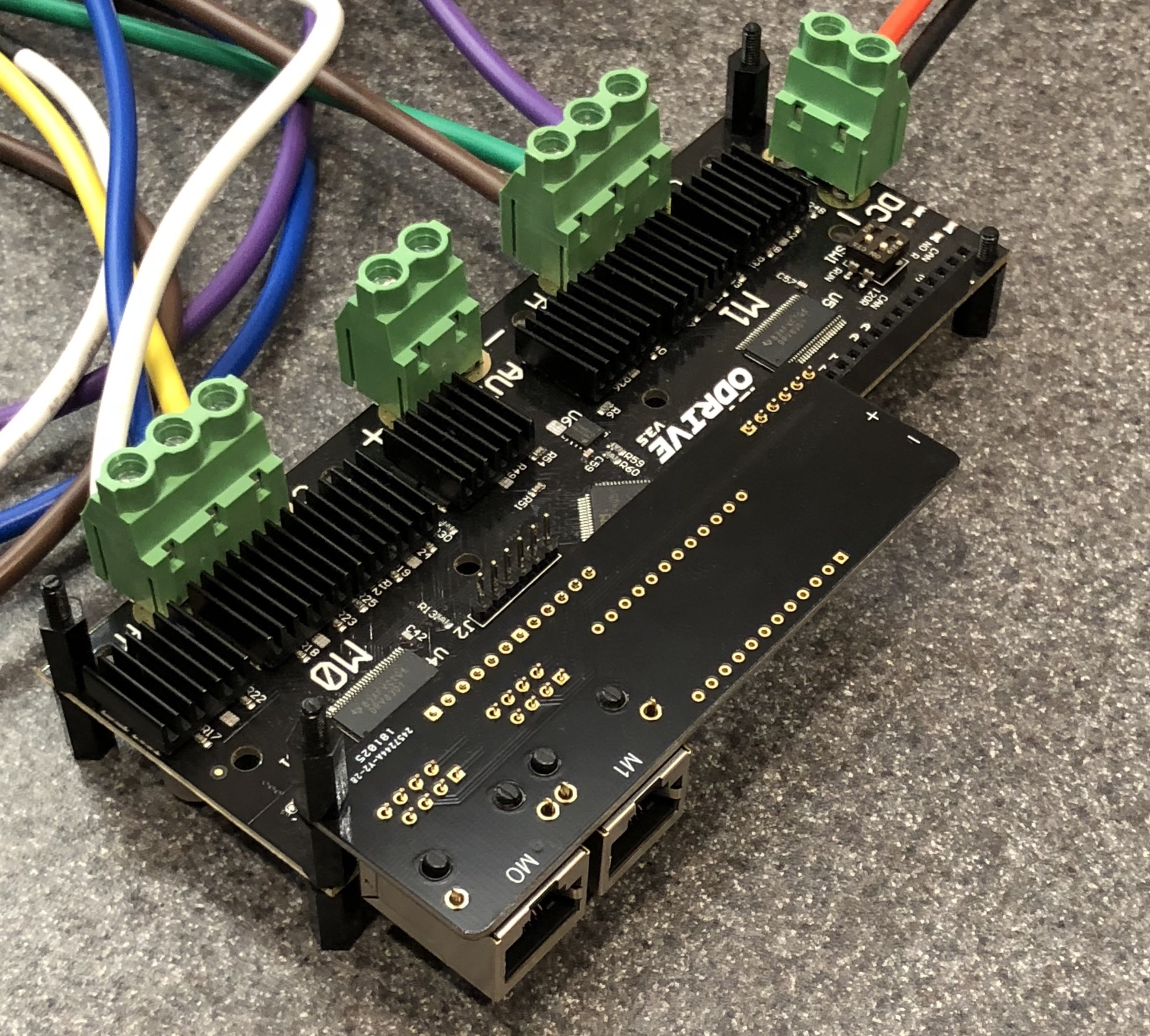

I am currently developing a project with a BLDC motor, and with an Odrive v3.5 controller, which I need to control the torque of the motor. To do some initial tests and get to know the Odrive controller, how can I program it to handle the torque control?

Thank you very much Gabrael and Congratulations!