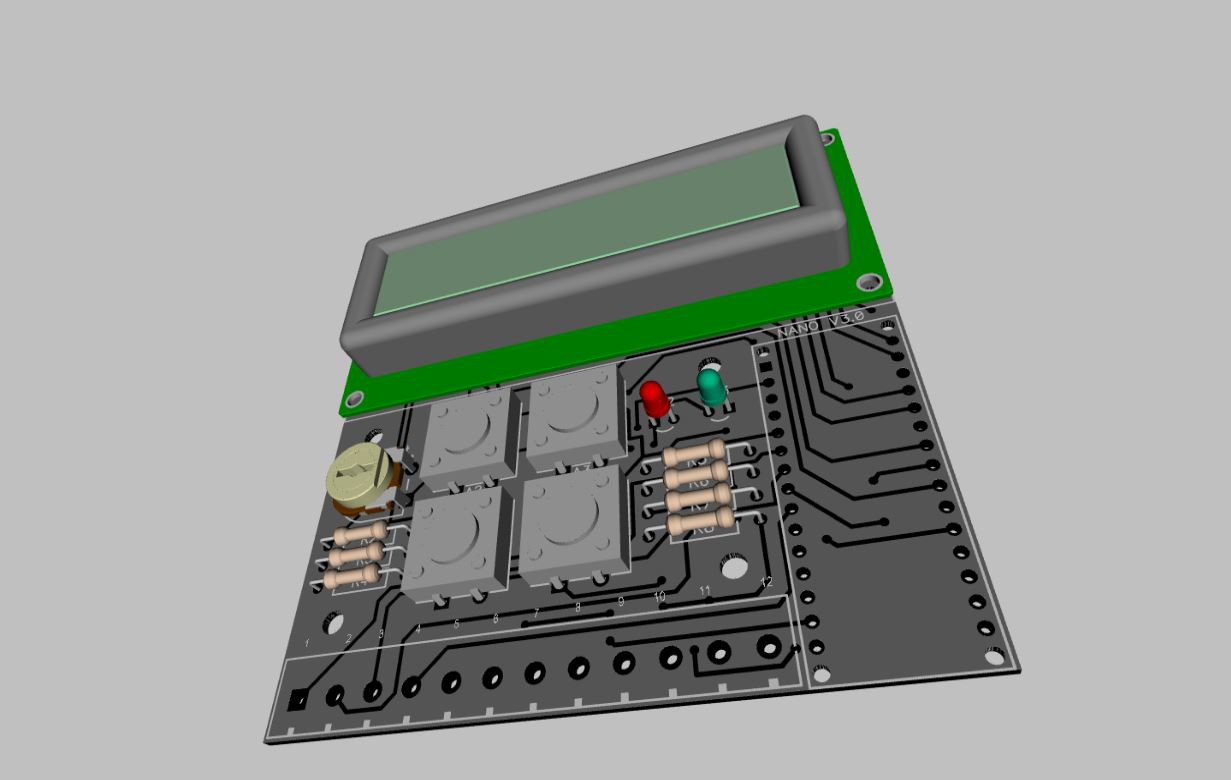

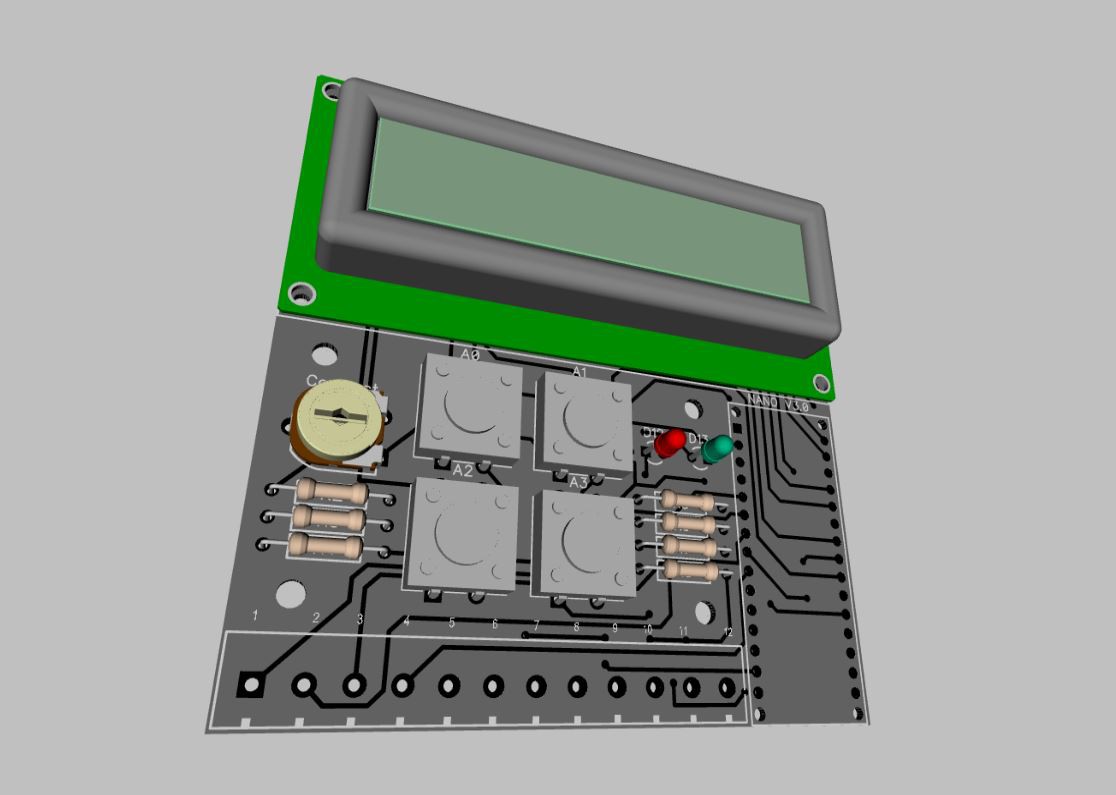

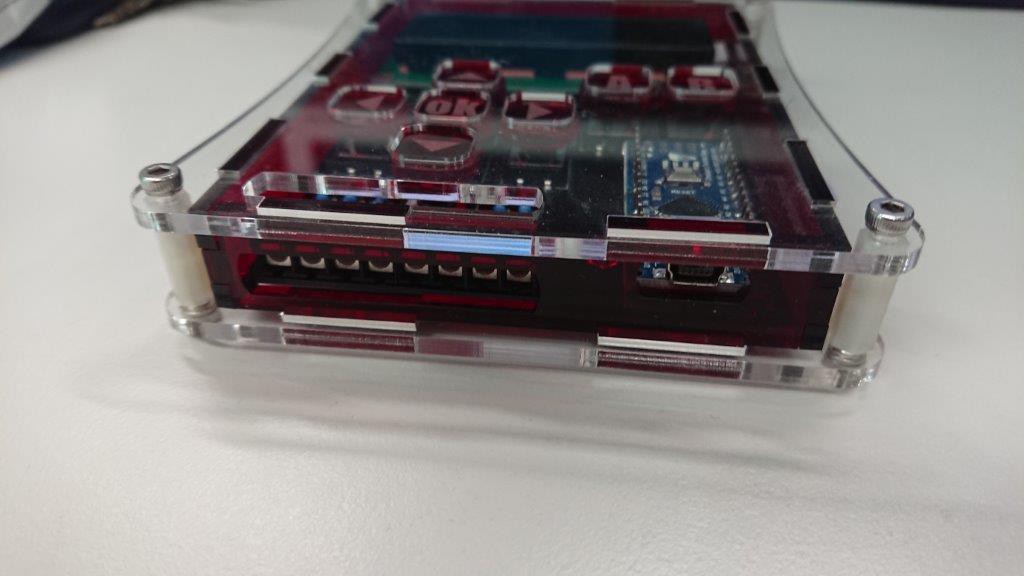

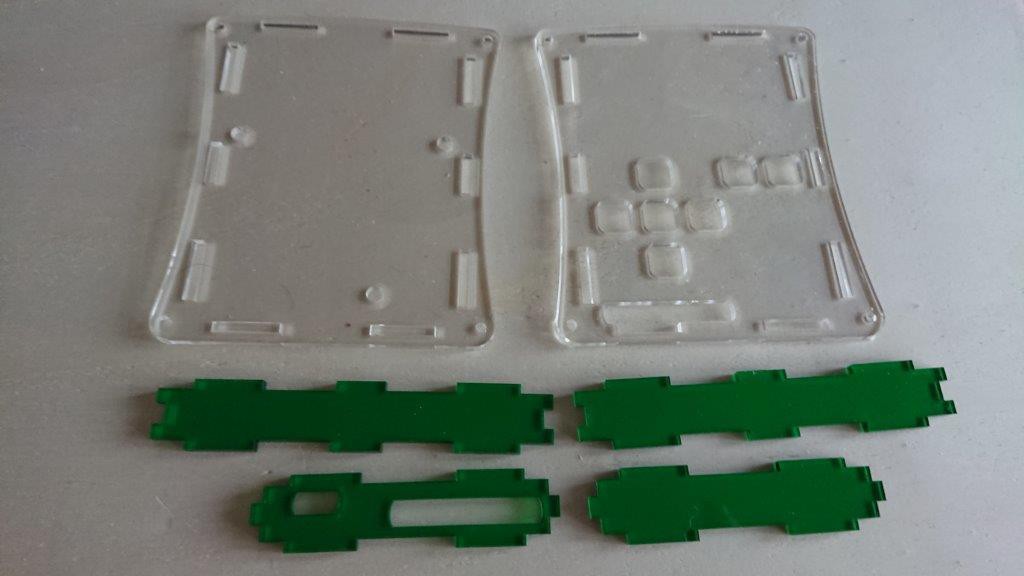

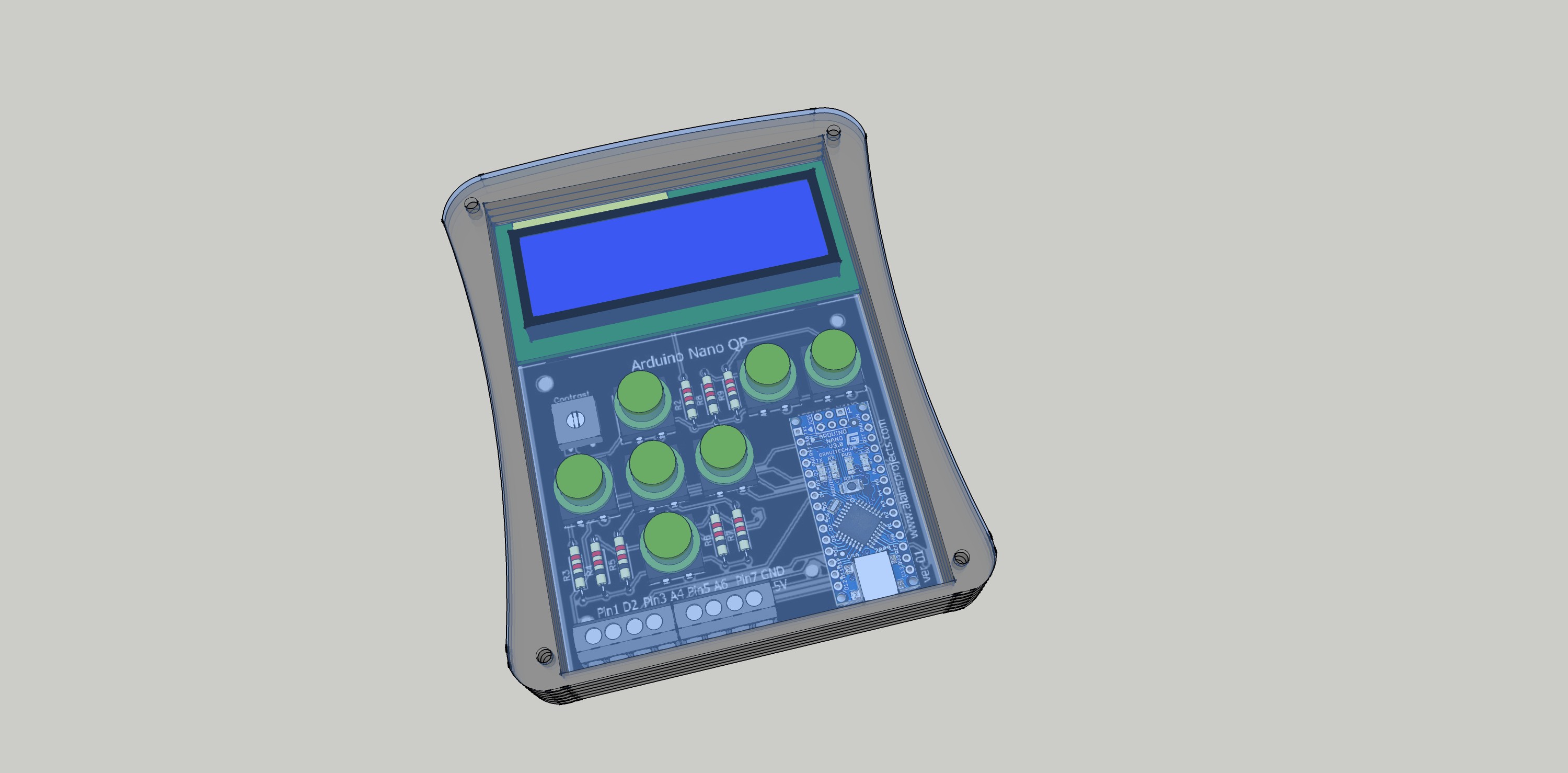

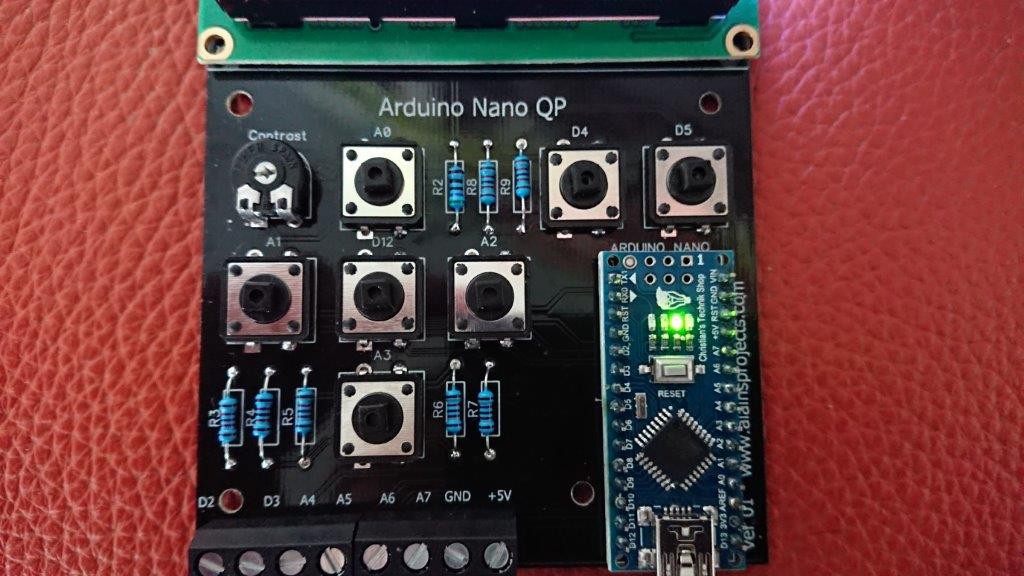

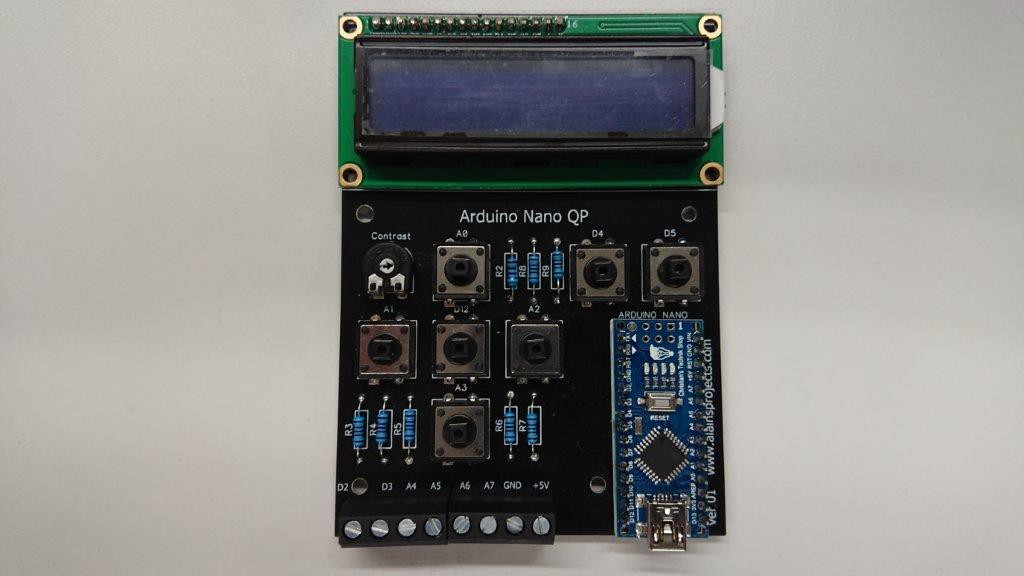

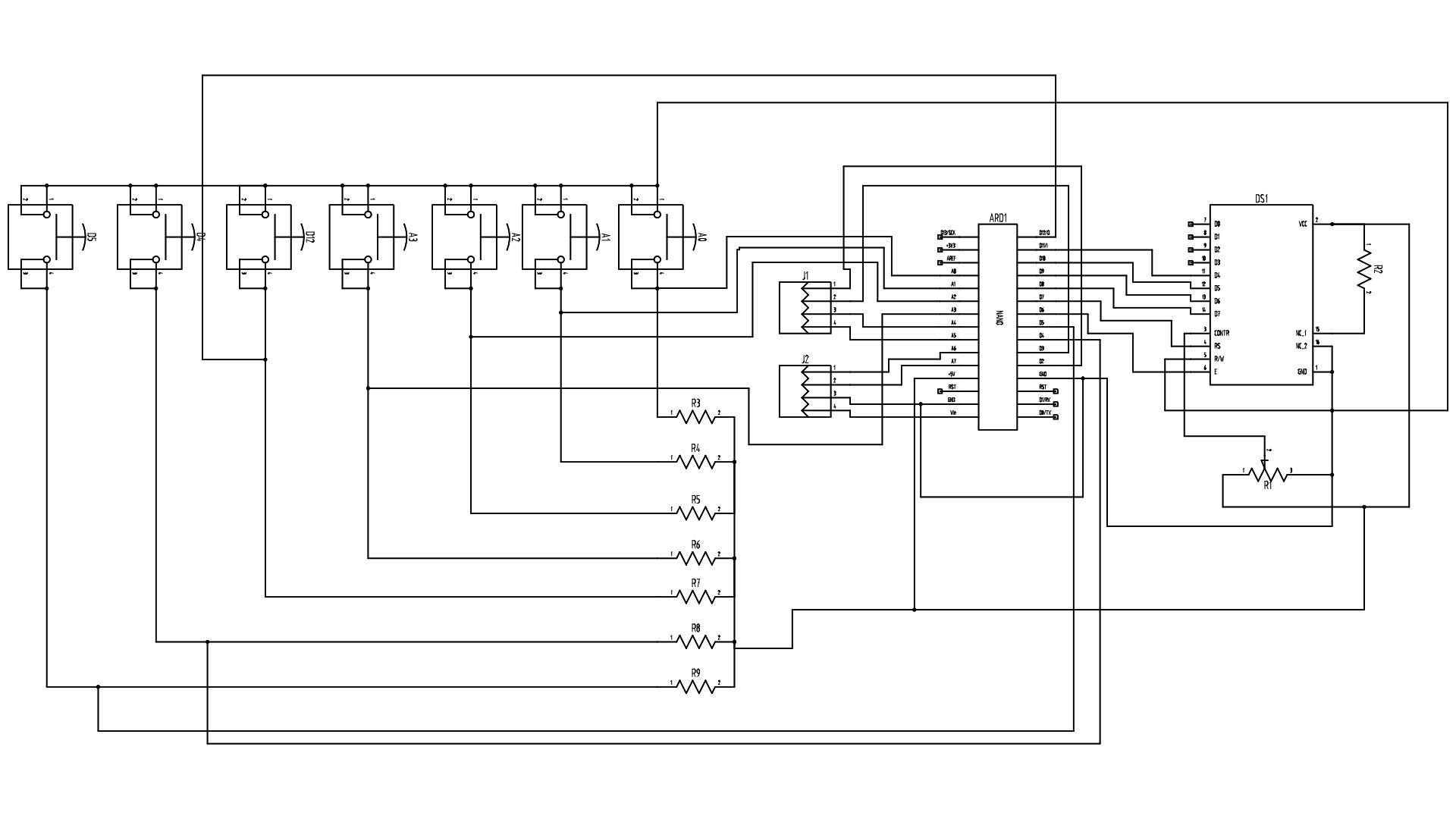

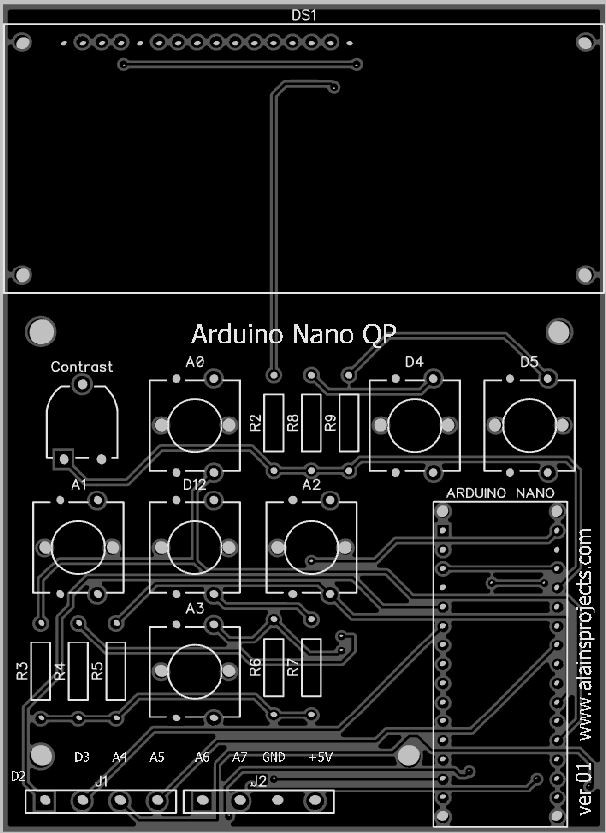

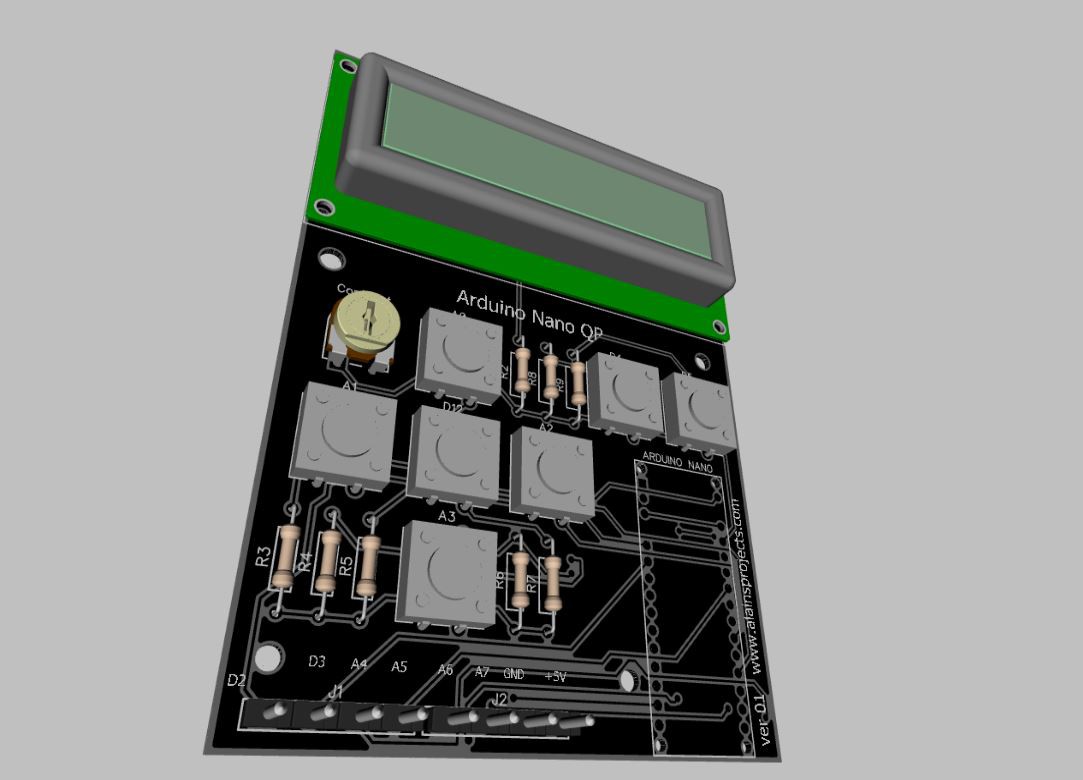

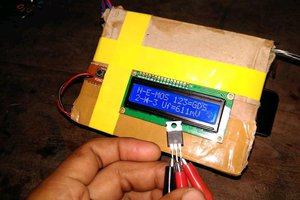

Do you also have the occasional problem, that you want to create something with an Arduino, but the workshop is a mess, you find neither a suitable display nor the right button, and finally, if you have everything together, you lost the desire, to realize the idea. That's why I have developed the Arduino Nano Quick Project.

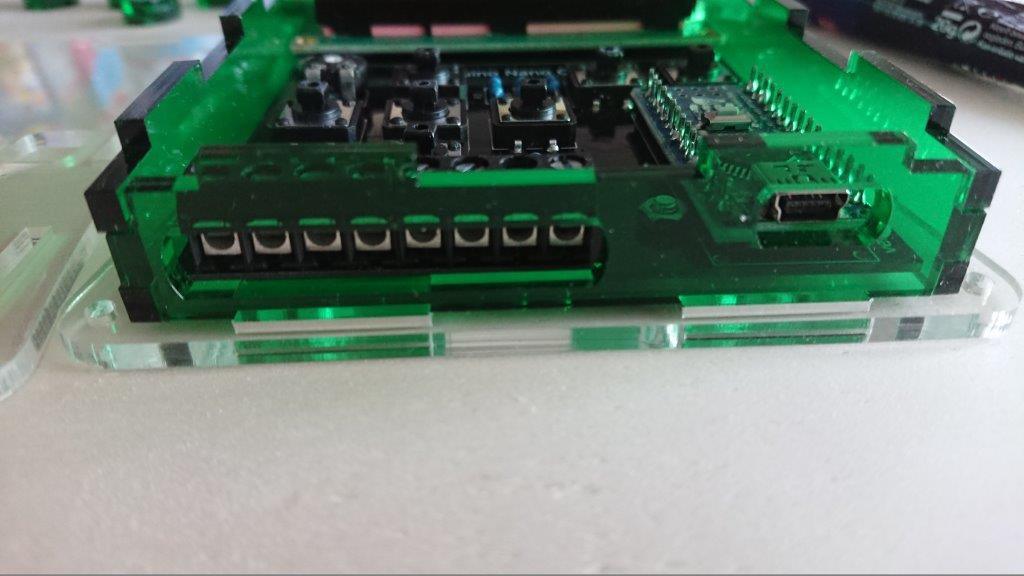

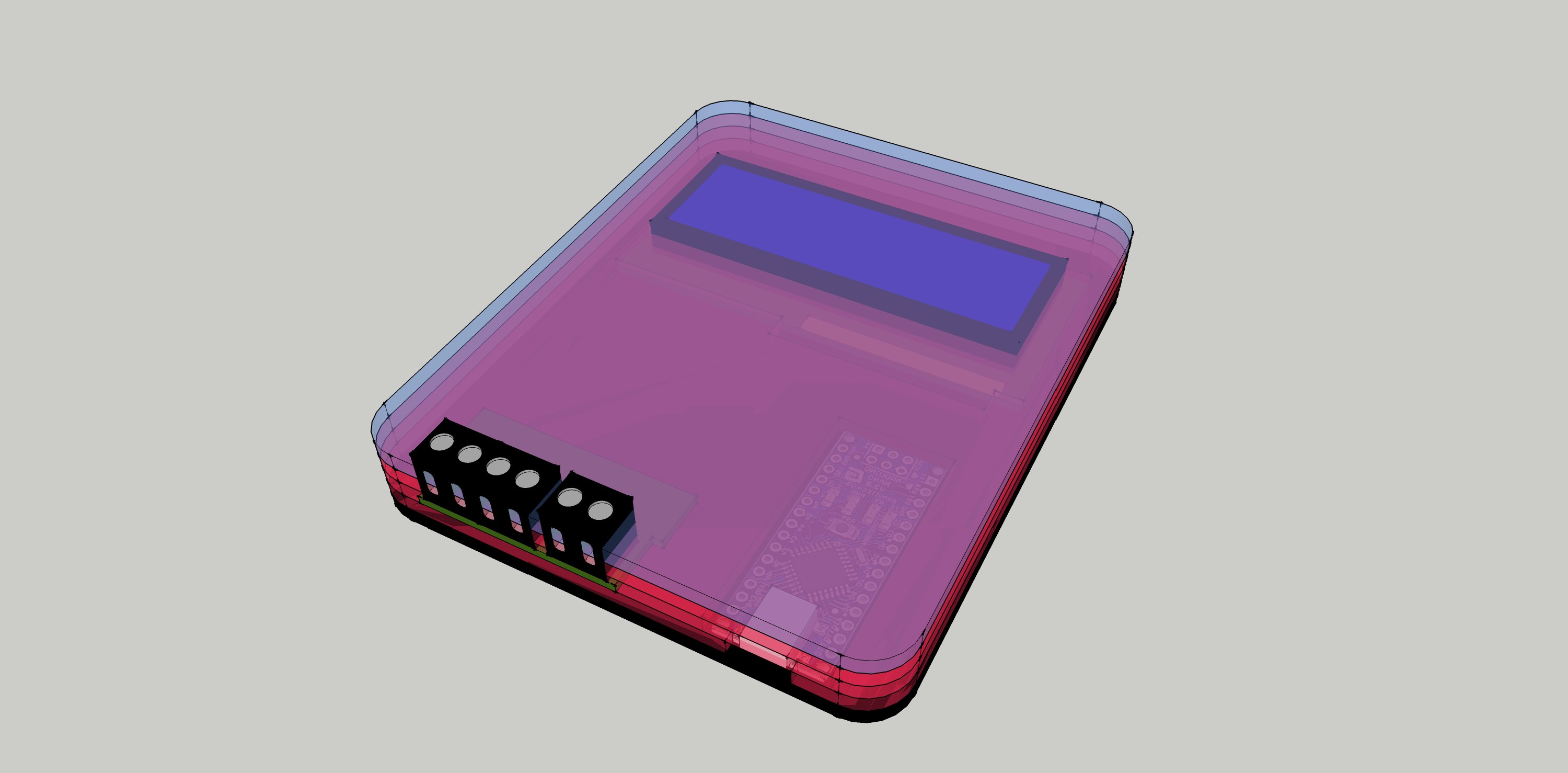

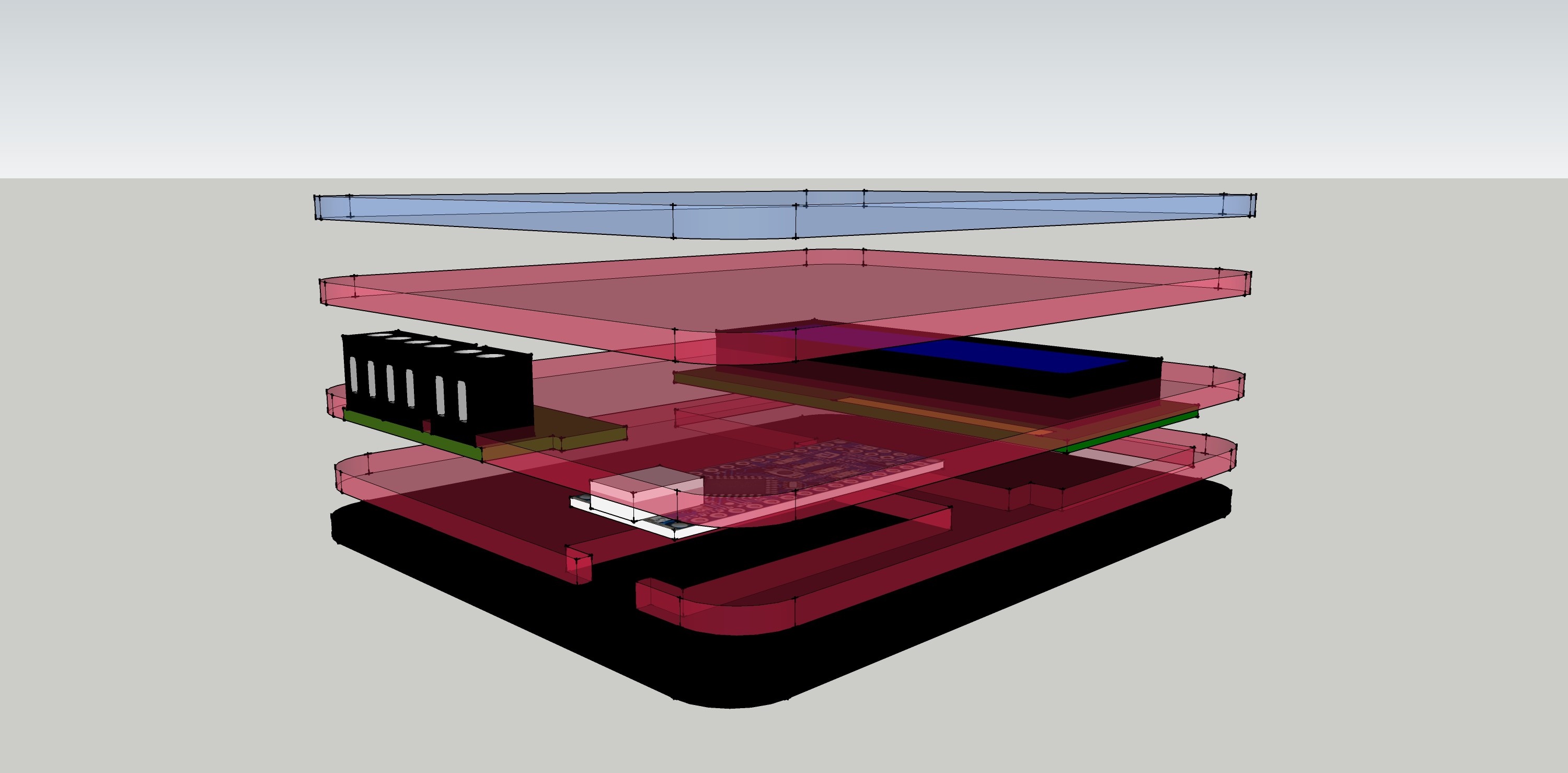

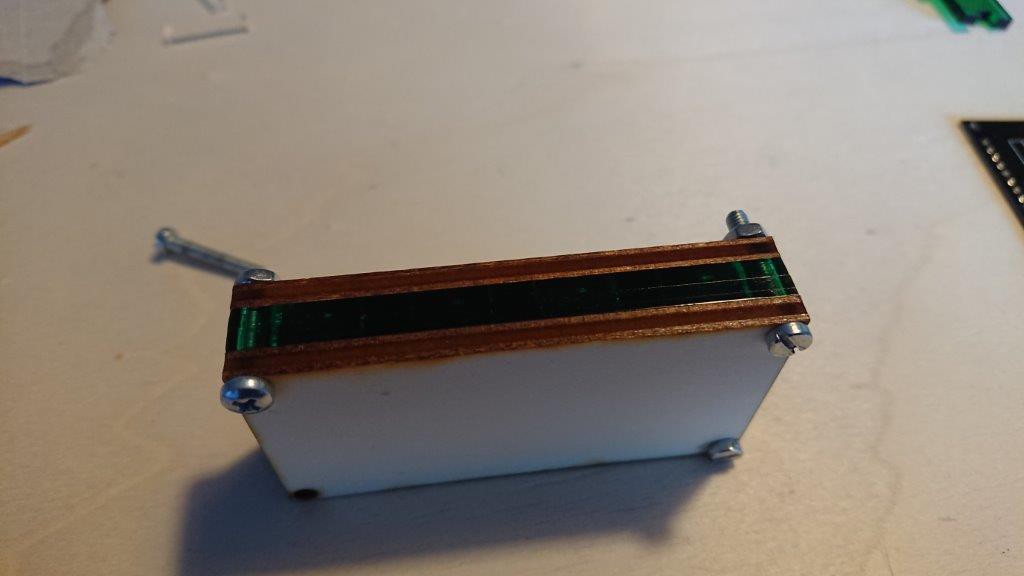

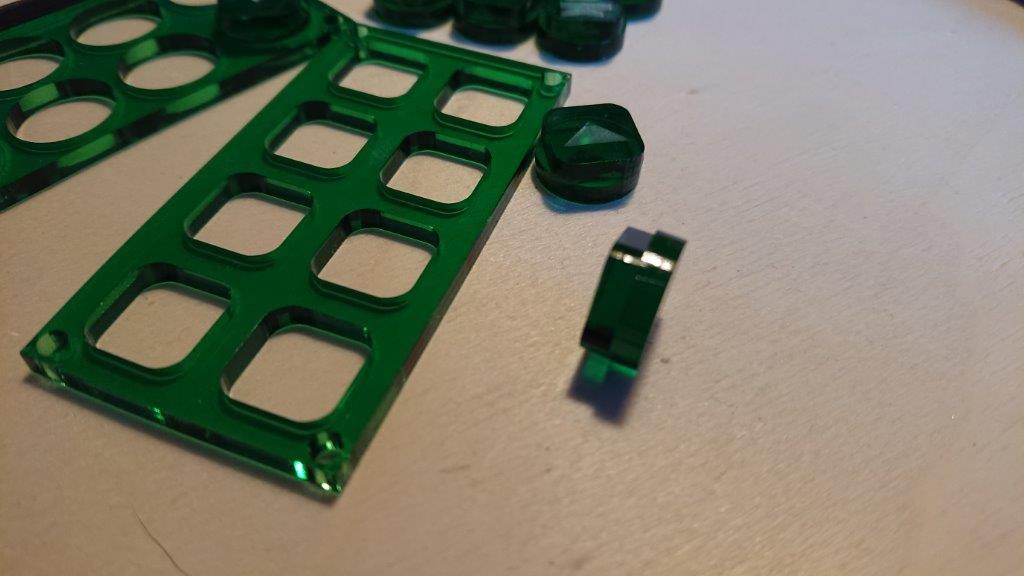

It's a ready to use box, which should be able to realize 85% of all the small ideas somebody can have. You have buttons, inputs, outputs, a display, serial (USB), a I2C interface and the onboard LED's. No more searching or soldering for a 10min project. Just take the Arduino Nano Q.P., upload your program and that's It. Use your Arduino where you want, in the lab, in the kitchen, in the bus ..... no more limits.

Alain Mauer

Alain Mauer

Jacob Christ

Jacob Christ

Romeo hackster

Romeo hackster

DIY GUY Chris

DIY GUY Chris

Jefferson Bueno

Jefferson Bueno

how contact you dear friend?