I constructed the prototype described in the previous log entry, with the buttons on top and display on the bottom. All the sensors worked perfectly (see previous log entry) and I got the display showing some text.

I mounted it on a prototype "neck unit" which is the formed wire support for use in hands free mode. Sorry I don't have a picture of the prototype with the buttons as I took it apart before taking pictures.

However what I learned from it was that the 80mm long mouthpiece housing just feels and looks too long. I decided that the mouthpiece module does not really need to contain the user interface because when used as a breath controller it could be configured with a host computer, and when used with a finger unit, the finger unit could contain the display. Also as a breath controller power could come over USB and when used with a finger unit, the finger unit could contain a battery.

Also making the holes in the housing for the display and buttons was an unnecessary complication in building mouthpiece models and I want assembly of the basic module to be as easy as possible.

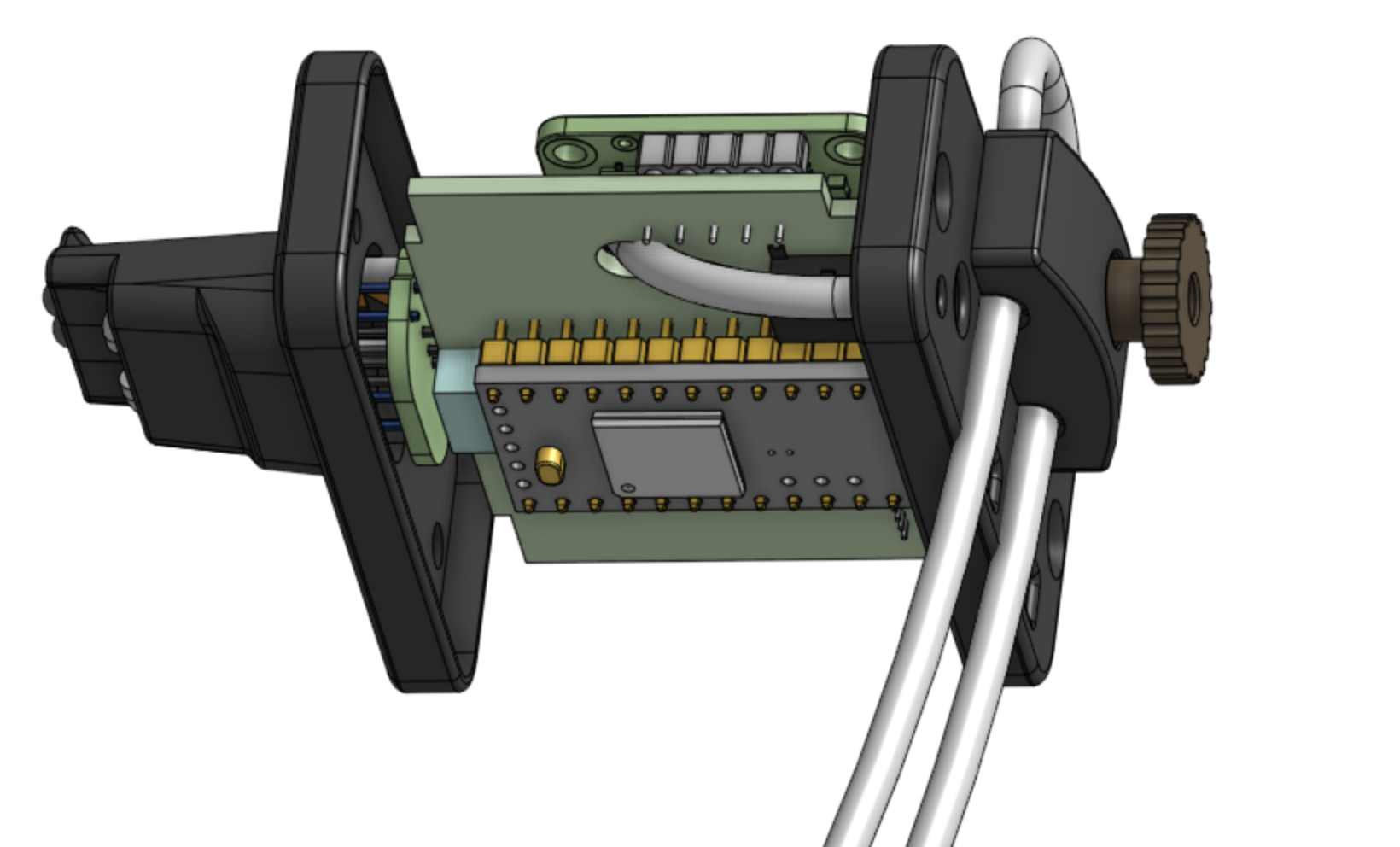

I eliminated the display and buttons from the mouthpiece module which allowed me to shorten it to 45mm long which feels and looks better:

The mouthpiece still includes a header to mount any of the three types of Adafruit IMUs. I also also added a MIDI out. The connector is a 2.5 mm TRS jack compatible with various 2.5mm to standard MID adapter cables that are available. You can see the MIDI connector in the opened image of the bottom of the PCB. It's the black component behind the tube on the lower right.

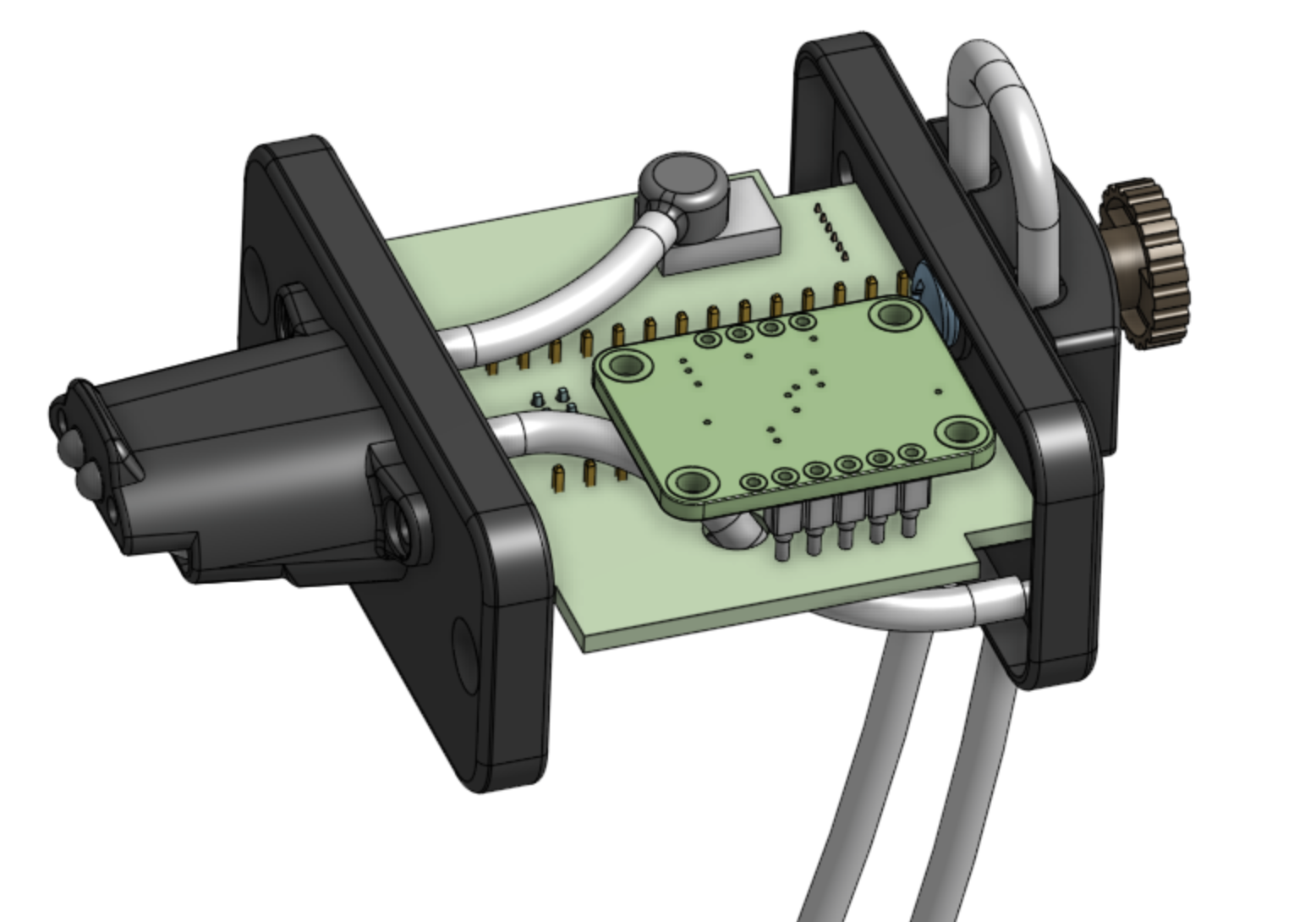

The mouthpiece still includes a header to mount any of the three types of Adafruit IMUs. I also also added a MIDI out. The connector is a 2.5 mm TRS jack compatible with various 2.5mm to standard MID adapter cables that are available. You can see the MIDI connector in the opened image of the bottom of the PCB. It's the black component behind the tube on the lower right.I then built a real version of the 3D model . Here are some pictures of the real assembled mouthpiece module on the formed wire neck unit.

You also see the mouthpiece mounted on a real "neck unit" for the first time. This is the support that allows it to be used as a hands free breath controller. This neck unit was hand made, which is quite challenging. I sent a 3D printed model of it to a wire forming company who should be able make them in large quantities if needed, very inexpensively.

The nice thing about this formed wire design is that it provides very stable support for the mouthpiece which is needed because the sensors are so subtle. Also the user can easily adjust the shape slightly for a perfect fit by hand-bending the steel wire. Yet another benefit is that the pivot has enough friction to hold the mouthpiece steady but the support can be tilted outward to temporarily get it out of the way and then brought back into position still perfectly aligned. Other breath controller supports (e.g. Yamaha BC3a or TEControl) tend to leave the mouthpiece in your mouth unless you remove it completely.

This mouthpiece housing you see here does not yet contain the circuit board. I designed a new version of the PCB and ordered some to be made. They should be here later this week.

If you look closely you can see another significant addition I made to the design: I added a small "fin" 3mm high across the top front of the mouthpiece. This is something I had in my best prototypes in the past but had eliminated to save cost. It allows the mouthpiece to be further stabilized using the upper lip or teeth. When I finally was able to try the current version of the mouthpiece on the neck unit I was reminded how much benefit came from the extra stabilization.

I realize it's unconventional to have a "fin" on the top of a mouthpiece as no existing instrument has it, but when you try it, it just feels even more perfect.

The fin causes an undercut for injection molding the mouthpiece shell which makes the mould more complex. I'm waiting to hear from Protomold whether they can make it and how much more it will cost. Based on past experience it could add about $1000 to the up-front cost of the mold but after that the unit cost of the mouthpiece shells should be about the same. I'm willing to pay this much because the benefits are significant.

Chris Graham

Chris Graham

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.